3DEXPERIENCE DELMIA

Efficiently Plan, Manage and Optimize Manufacturing Operations

What is 3DEXPERIENCE DELMIA?

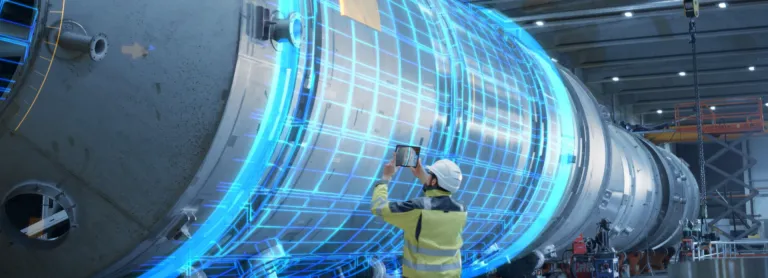

The 3DEXPERIENCE DELMIA platform seamlessly connects the virtual and real aspects of value networks. It empowers companies to enhance operations swiftly, fostering innovation and new business models.

With a four-step framework — Model, Perform, Optimize, and Collaborate — it ensures agile, resilient, and globally responsive operations. Through 3D solutions, the platform allows for virtual modeling of enterprises, enabling design, simulation, testing, and training of supply chains, assets, products, and processes. The Virtual Twin Experience provides an accurate virtual model, minimizing costs and waste, and accelerating planned changes.

The 3DEXPERIENCE platform offers flexibility, allowing real-time access to actionable intelligence and reporting from the Virtual Twin Experience model, driving operational efficiency and continuous improvement.

Explore the transformative impact of DELMIA 3DEXPERIENCE across various business processes and subdisciplines within your organization.

5 Benefits of 3DEXPERIENCE DELMIA

3DEXPERIENCE DELMIA offers a range of benefits across various industries, especially in the realm of digital manufacturing and engineering.

End-to-End Digital Continuity

3DEXPERIENCE DELMIA provides a unified platform that connects different stages of the product lifecycle, fostering seamless collaboration and ensuring digital continuity from design through manufacturing to service.

Improved Collaboration

The platform facilitates collaboration among multidisciplinary teams, allowing designers, engineers, and other stakeholders to work together in a shared environment.

This can lead to enhanced communication, faster decision-making, and a more integrated approach to product development.

Efficient Digital Manufacturing

DELMIA's digital manufacturing solutions, including simulation and virtual validation tools, help optimize production processes, reduce costs, and minimize the need for physical prototypes.

This efficiency can lead to quicker time-to-market for products.

Enhanced Productivity

With features like process optimization, workflow management, and virtual prototyping, 3DEXPERIENCE DELMIA aims to improve overall productivity in product development and manufacturing.

It allows for better planning, validation, and execution of processes.

Innovative Product Design

The platform supports innovative product design through advanced 3D modeling and simulation capabilities.

Designers can explore ideas, iterate quickly, and validate concepts in a virtual environment before committing to physical prototypes.

DELMIA Key Subdisciplines

Enable Digital Continuity Between Design and Production

Boost precision, reduce programming time, and streamline workflows with DELMIA’s advanced CAM automation for efficient manufacturing.

Enhance precision, efficiency, and scalability in 3D printing with DELMIA’s advanced additive manufacturing solutions for polymer and metal production.

Achieve and Sustain Manufacturing Excellence with an Enterprise Approach

Effectively Fulfill Requirements to Meet Forecasted Demand

Finding and Solving Ergonomic Problems in 3D for Safer Workplace in Real Life

Connect People, Ideas, Data and Processes

Optimize Resources, Increase Quality, Eliminate Waste

Optimize Operations with a Unified Monitoring Environment

Unlock the Factory of Tomorrow, Today

Unlock the Potential of Service Operations

DELMIA software products are packaged as Roles on the 3DEXPERIENCE platform to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

What's New in DELMIA R2025x

Introducing groundbreaking solutions to streamline your robotic material handling, predict and prevent 3D printing issues, and create and manage 3D work instructions

DELMIA manufacturing and production continues to broaden its extensive portfolio with new introductions in Robotics, Additive Manufacturing, and Process Engineering. These new roles enhance crucial functions within each discipline and aim to further enhance the capabilities of the 3DEXPERIENCE platform.

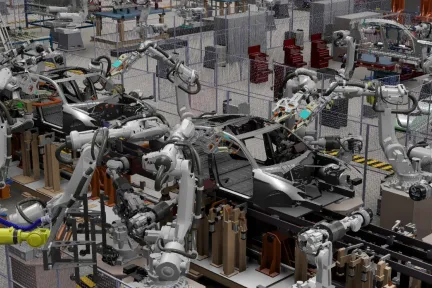

DELMIA Robotics is revolutionizing Robotic material handling with a new solution that automates design and programming, including palletizing. DELMIA Material Handling Robot Programmer comes with a user-friendly interface that helps to configure your robotic system, providing offline programming without disrupting production. It provides a robot palletizing simulation that helps to visualize and optimize palletizing patterns with conveyors and sensors.

DELMIA Process Engineering’s new cloud-based solution empowers you to author, update, and publish textual as well as 3D Work Instructions. Work Instructions Creator uses Manufacturing and Service processes and operations as input for authoring work instructions in the right 3D context thanks to the build-up calculation functionality.

And finally, DELMIA Additive Manufacturing’s innovative new role, Additive Manufacturing Quality Analyst leverages the power of data to identify potential issues and forecast the shape of the next part based on previous prints. This is accomplished through the analysis of historical data to spot potential problems. This proactive approach enables successful production runs, ultimately driving significant cost savings and improving time-to-market.

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

With the help of the 3DEXPERIENCE platform, we transform the way we work within our business unit and innovate to continue offering our products at a competitive price.

Useful Resources

FAQs

You can visit the 3DEXPERIENCE platform Resource Center to access the latest insights, customer stories, and other resources related to the 3DEXPERIENCE platform. The Resource Center is a repository for all information on the Dassault Systèmes 3DEXPERIENCE platform.

Additionally, you can check out the 3DEXPERIENCE Edu SPACE, an online learning portal that provides learning experiences for Dassault Systèmes products and solutions. The portal offers learning resources by domain, industry, and product, and can be accessed anywhere, anytime.

Discover More DELMIA Products

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering