Robotics

Enabling digital continuity between design systems and robotic simulation for seamless integration into manufacturing workflows.

What is DELMIA Robotics Software?

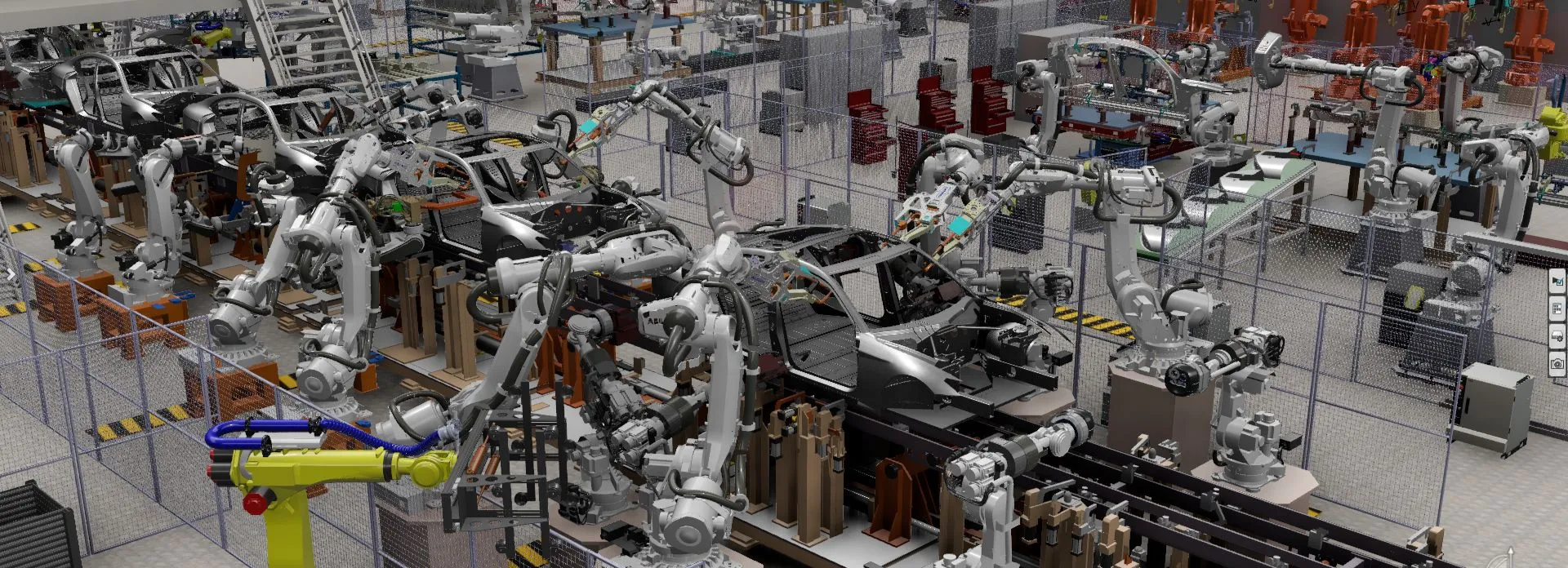

DELMIA Robotics validates production systems and robot programming within a 3D collaborative environment. Robotics software continues to evolve with advancements in artificial intelligence and machine learning technologies. These innovations have opened new horizons for robot simulation, programming and modeling across various industries.

Part of the 3DEXPERIENCE platform, it enables manufacturers to virtually design, program, and optimize robotic systems with speed and precision. Define robotic work cells, program and optimize robots and simulate the manufacturing environment and product flow virtually, reducing the need for physical trials and accelerating deployment on the shop floor. This facilitates offline robot programming without disrupting production while providing accurate virtual validation using virtual twin technology to save time and cost.

Robotics Software Ranked #1 Offline Programming by ABI Research

DELMIA Robotics software has secured the top spot in ABI Research’s prestigious Technology Vendor Competitive Rankings. DELMIA Robotics software stood out for its comprehensive capabilities, offering an unparalleled solution for simulating, validating, and optimizing production systems and robotic programming—all within an immersive 3D collaborative environment. This enables manufacturers to fine-tune every aspect of their production processes before real-world implementation, significantly enhancing operational efficiency and productivity.

Integrate Robot Programming & Modeling in Production

Seamlessly integrated with CATIA, SOLIDWORKS, and the broader DELMIA Industrial Engineering portfolio, DELMIA Robotics software delivers true digital continuity.

It connects product design, process planning, robotic simulation, and production execution in a single collaborative environment.

Global Reach, Local Support

Support and sales teams in 100+ countries. Access to a strong expert partner network that provides specialized assistance and integration services.

Up to 80% Reduction in Robot Programming Time

Our customers have reported reduction in programming time by up to 80% through offline robot programming and reuse of existing code.

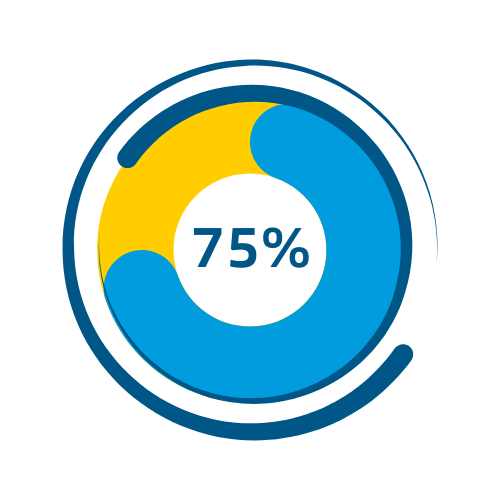

Up to 75% Reduction in Commissioning Time

Virtual commissioning capabilities allow manufacturers to simulate and validate robot programs before deployment, reducing physical commissioning time by 75%.

Faster ROI Within the First Year

The cost savings from reduced programming and commissioning times typically result in a return on investment within the first year of deployment.

DELMIA Robotics Software Capabilities

A single source of truth for product and process engineers.

- Material Handling

- Curve Simulation

- Virtual Commissioning

- Spot Simulation

- Surface Simulation

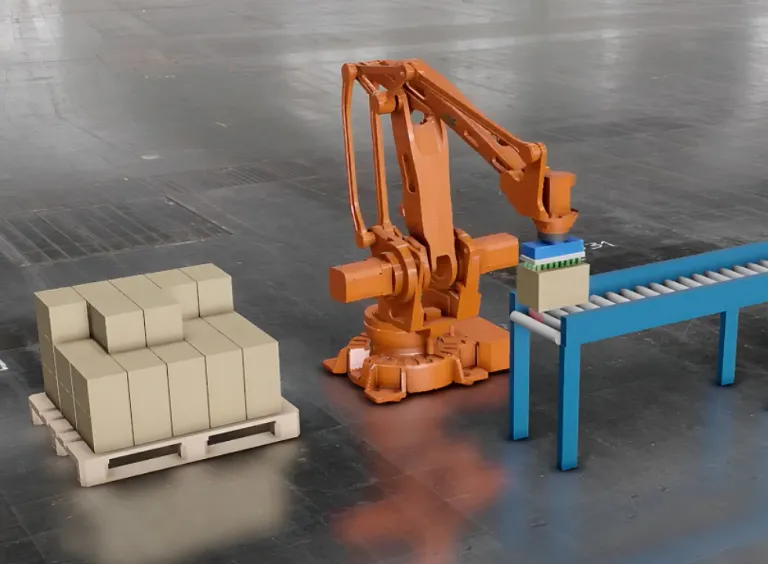

Material Handling

Generate complete palletizing programs in a few clicks. DELMIA Robotics Material Handling is a software solution designed with the user in mind.

The application allows for easy creation of palletizing programs. Our wizard guides you through the whole process, from resource definition, to product/pallet layout and simulation.

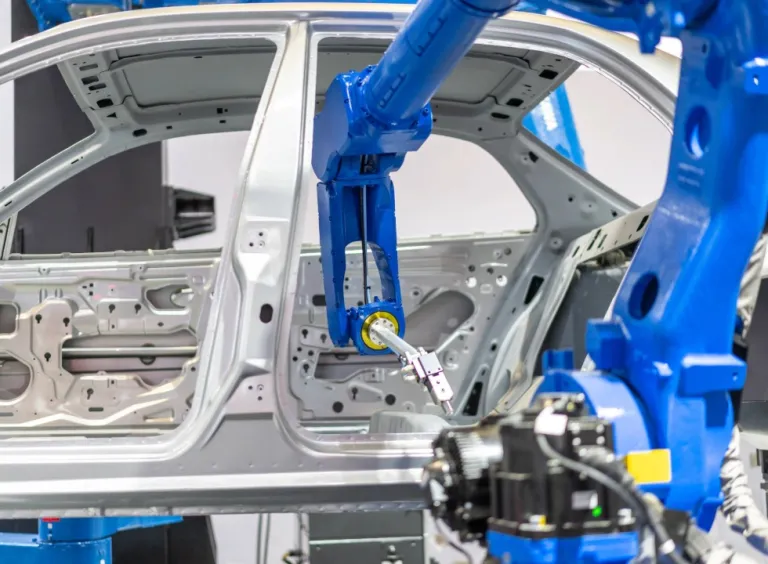

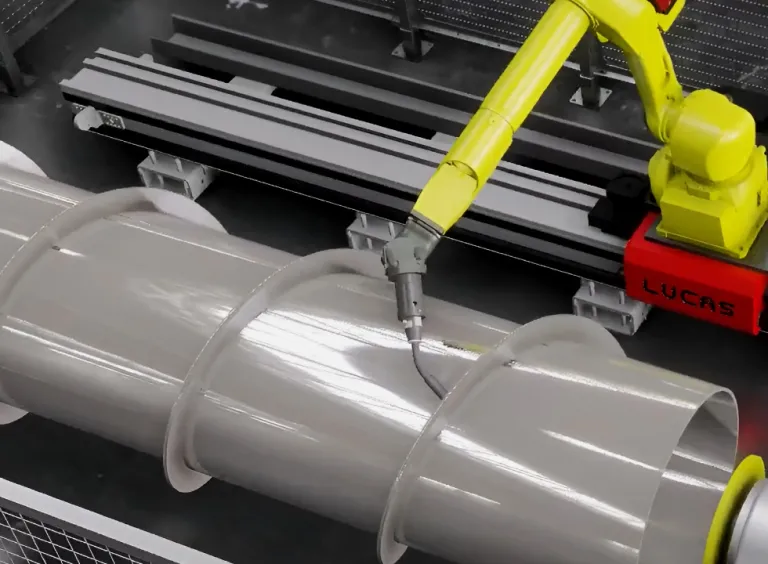

Curve Simulation

Our solution for continuous robotics processes. DELMIA Robotics Curve Simulation is a software solution that allows users to easily program robots for curve-based processes like arc welding, glue deposition, etc.

Virtual Commissioning

Our solution for Virtual Commissioning of robotic systems. DELMIA Robotics Virtual Commissioning is a software solution that allows users to easily program robots and communicate with a virtual PLC.

The software model and hardware in the loop are all supported through DELMIA Virtual Commissioning and CATIA Control Build.

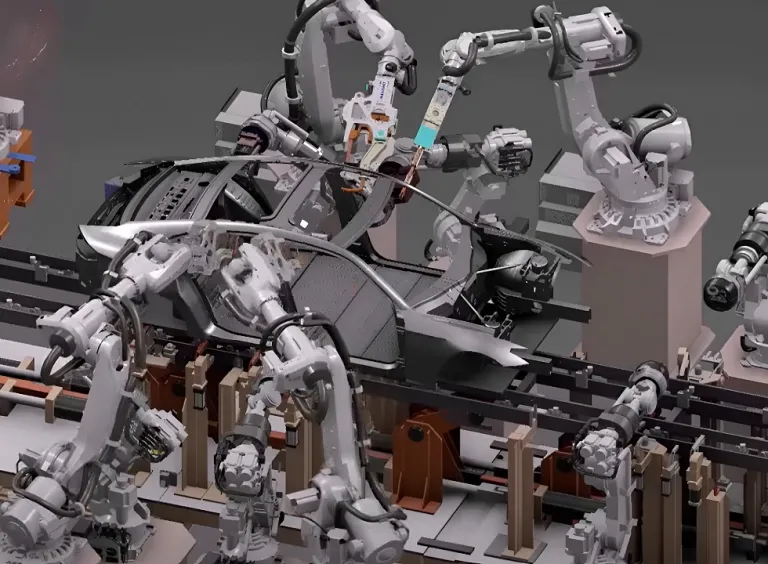

Spot Simulation

Our solution for point-based robotics processes. DELMIA Robotics Spot Simulation is a software solution that allows users to easily program robots for point-based processes like spot welding for automotive body-in-white or drilling and riveting for aerospace.

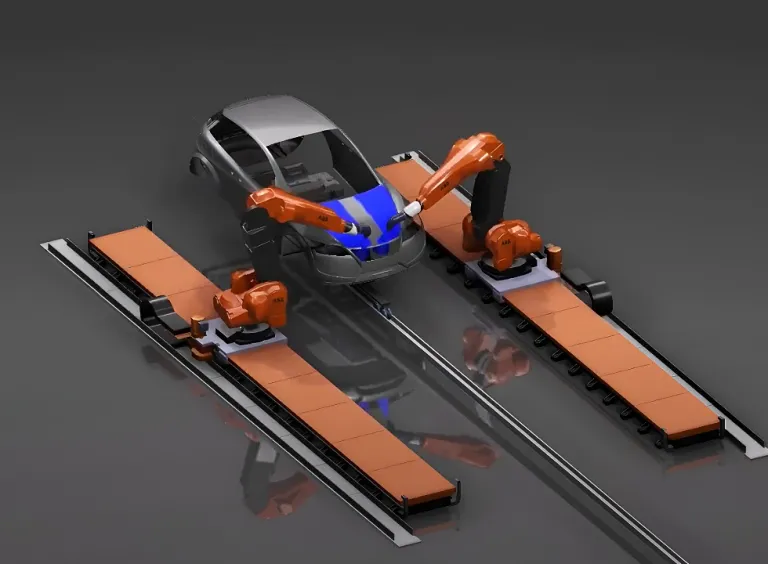

Surface Simulation

Our solution for surface robotics processes. DELMIA Robotics Surface Simulation is a software solution that allows users to easily program robots for surface-based processes like painting, polishing, laser Ablation, Shot Peening, etc.

Key Benefits of DELMIA Robotics Software

DELMIA Robotics Software & Virtual Twin Technology

Create a living virtual twin powered by generative capabilities—import point cloud data to automatically reconstruct real-world environments, enabling precise, continuously updated simulations for accurate decision-making.

- Test and validate robot programs offline without disrupting production

- Simulate complex manufacturing processes with realistic physics

- Optimize robot trajectories and cycle times before deployment

- Train operators in a risk-free virtual environment

- Troubleshoot issues without physical equipment access

DELMIA Robotics Software & Roles

DELMIA Robotics software empowers professionals across various disciplines to excel in their specific roles within the robotics implementation process. Each role-based package provides targeted functionality to address the unique challenges and requirements of particular applications.

Robotics Software Customer Success Stories

Discover how industry leaders like Robot at Work, Yutaka Electronics, CNBM Triumph Robotics, Prodomax, and CIS Optim'Axes use DELMIA Robotics software to simulate, design and program.

We are now selling complete logistics solutions on DELMIA, and we’ve seen revenue in our robotics business line double in the last year alone.

Start Your Journey

The world of robotics is changing. Discover how to stay a step ahead with DELMIA Robotics software.

DELMIA Robotics Software at Work

Video Gallery

FAQ about Robotics Software

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering