3DEXPERIENCE DELMIA

Efficiently Plan, Manage and Optimize Manufacturing Operations

What is 3DEXPERIENCE DELMIA?

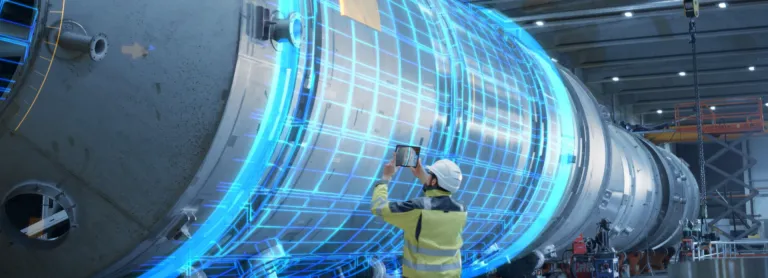

The 3DEXPERIENCE DELMIA platform seamlessly connects the virtual and real aspects of value networks. It empowers companies to enhance operations swiftly, fostering innovation and new business models.

With a four-step framework — Model, Perform, Optimize, and Collaborate — it ensures agile, resilient, and globally responsive operations. Through 3D solutions, the platform allows for virtual modeling of enterprises, enabling design, simulation, testing, and training of supply chains, assets, products, and processes. The Virtual Twin Experience provides an accurate virtual model, minimizing costs and waste, and accelerating planned changes.

The 3DEXPERIENCE platform offers flexibility, allowing real-time access to actionable intelligence and reporting from the Virtual Twin Experience model, driving operational efficiency and continuous improvement.

Explore the transformative impact of DELMIA 3DEXPERIENCE across various business processes and subdisciplines within your organization.

5 Benefits of 3DEXPERIENCE DELMIA

3DEXPERIENCE DELMIA offers a range of benefits across various industries, especially in the realm of digital manufacturing and engineering.

End-to-End Digital Continuity

3DEXPERIENCE DELMIA provides a unified platform that connects different stages of the product lifecycle, fostering seamless collaboration and ensuring digital continuity from design through manufacturing to service.

Improved Collaboration

The platform facilitates collaboration among multidisciplinary teams, allowing designers, engineers, and other stakeholders to work together in a shared environment.

This can lead to enhanced communication, faster decision-making, and a more integrated approach to product development.

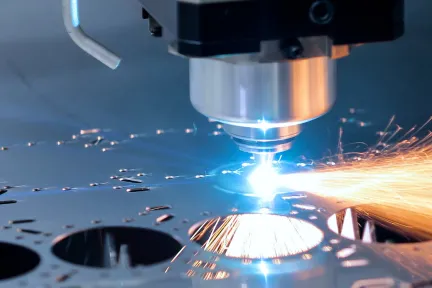

Efficient Digital Manufacturing

DELMIA's digital manufacturing solutions, including simulation and virtual validation tools, help optimize production processes, reduce costs, and minimize the need for physical prototypes.

This efficiency can lead to quicker time-to-market for products.

Enhanced Productivity

With features like process optimization, workflow management, and virtual prototyping, 3DEXPERIENCE DELMIA aims to improve overall productivity in product development and manufacturing.

It allows for better planning, validation, and execution of processes.

Innovative Product Design

The platform supports innovative product design through advanced 3D modeling and simulation capabilities.

Designers can explore ideas, iterate quickly, and validate concepts in a virtual environment before committing to physical prototypes.

DELMIA Key Subdisciplines

DELMIA software products are packaged as Roles on the 3DEXPERIENCE platform to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

What's New in DELMIA R2024x

Introducing new features in DELMIA Manufacturing & Production!

- DELMIA Virtual Factory now includes the Factory Layout Designer, a user-friendly 3D tool that validates and optimizes factory layout plans, reducing costs and expediting production ramp-up. It accommodates brownfield scenarios using 3D scans for virtual layout adjustments.

- In DELMIA Sales & Operations Planning, the Inventory Planner, a cloud-only role, ensures optimal inventory levels by managing quantity, location, and timing. It enables planners to share crucial demand and supply information, contributing to inventory optimization.

- DELMIA Fabrication introduces Collaborative NC Engineer for Machine Code Simulation, streamlining the integration of external NC machine code simulation systems with DELMIA Machining on the 3DEXPERIENCE platform. This reduces program validation time and simplifies error correction, enhancing efficiency in NC programming.

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

With the help of the 3DEXPERIENCE platform, we transform the way we work within our business unit and innovate to continue offering our products at a competitive price.

Useful Resources

FAQs

You can visit the 3DEXPERIENCE platform Resource Center to access the latest insights, customer stories, and other resources related to the 3DEXPERIENCE platform. The Resource Center is a repository for all information on the Dassault Systèmes 3DEXPERIENCE platform.

Additionally, you can check out the 3DEXPERIENCE Edu SPACE, an online learning portal that provides learning experiences for Dassault Systèmes products and solutions. The portal offers learning resources by domain, industry, and product, and can be accessed anywhere, anytime.

Discover More DELMIA Products

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering