DELMIA Quintiq

Drive Continuous Improvements across the Supply Chain

What is DELMIA Quintiq?

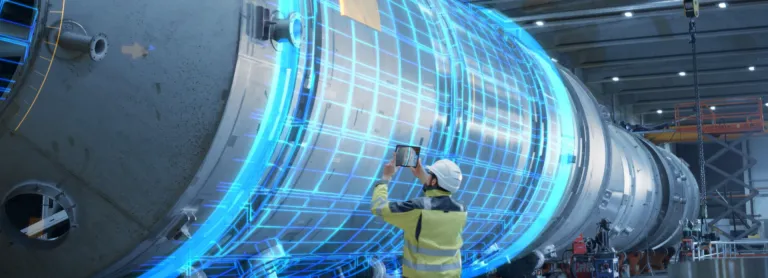

DELMIA Quintiq is a market leader in supply chain planning and optimization. It provides organizations with end-to-end supply chain modeling solutions to balance operational and business goals, leveraging world record-breaking optimization technology. As with all DELMIA products, DELMIA Quintiq connects the virtual and real worlds so that organizations can create a virtual twin of the supply chain. Achieve supply chain optimization with DELMIA Quintiq, driving continuous improvement across the entire supply chain. Leveraging Artificial Intelligence (AI) and Machine Learning (ML), it delivers real-time visibility and collaborative synchronization across all planning and operations stakeholders within the organization and the extended value network. Manufacturers and service providers can plan and optimize any or all areas of their supply chain—from complex global production, detailed logistics and diverse workforce operations.

DELMIA Quintiq supports Planning & Scheduling of Manufacturing and the Supply Chain, Logistics and the Workforce with key capabilities, such as predictive and prescriptive data analytics and forecasting. In addition, it provides unlimited what-if scenario and business-based KPI planning to enable agile decision-making and mitigate the impact of disruptions. With DELMIA Quintiq, manufacturing planners and organizations can build resilient supply chains to improve productivity and efficiency, ensure on-time delivery with shorter lead times and take advantage of opportunities for innovation and sustainable growth.

Discover DELMIA Quintiq solutions for seven domains: Advanced Analytics for enhanced reporting & analysis, Logistics Planning for increased profitability, Optimized Supply Planning for performance efficiency, Production and Sales & Operations Planning for higher ROI, Rail Planning for higher service levels and, finally, Workforce Scheduling for employee productivity.

Benefits of DELMIA Quintiq

Enhanced Supply Chain Efficiency

By establishing a cohesive ecosystem that facilitates seamless collaboration among crucial external partners, cutting-edge technology introduces flexibility and resilience into supply chain optimization. This mitigates the adverse effects of disruptions, ensuring smooth operations and enabling manufacturers to sustain continuity across their supply chains.

Holistic Connectivity in Systems

Utilizing the 3DEXPERIENCE platform, you have the capability to link essential touchpoints across the manufacturing, engineering, sales and operations, and supply chain domains within a unified ecosystem. This ensures coordinated decision support for Integrated Business Planning and operations.

Advanced Optimization Technology

DELMIA Quintiq is comprised of a synergy of five robust technologies: mathematical programming, constraint programming, path optimization algorithms, graph programming, and a proprietary configuration language.

Key Features of DELMIA Quintiq

- Advanced Planning and Optimization

Utilizes advanced algorithms and optimization techniques to enhance planning processes, ensuring efficiency and cost-effectiveness. - Real-time Decision Support

Provides real-time insights and data analytics to support informed decision-making across various operational aspects. - Visibility and Control

Provides comprehensive visibility and control over various aspects of operations, allowing managers to monitor and manage processes in real-time. - User-Friendly Interface

Features an intuitive and user-friendly interface to facilitate easy navigation and use by planners, managers, and other users. - KPI Monitoring

Includes key performance indicator (KPI) monitoring and reporting tools to track and measure the success of planning and optimization efforts. - Supply Chain Visibility

Enhances supply chain visibility by tracking and managing the movement of goods, inventory levels, and production processes.

DELMIA Quintiq Solutions

Predictive Analytics Software for Greater Insight

Create Profitable Logistics Plans from the First to Last Mile

Optimized Planning Software for Higher ROI and Performance Efficiency

Support your Production with Powerful Planning Software

Improve Your Railway Operations

Strategically Plan and Optimize Your Business End-to-End

Integrate planning and scheduling processes in a single workforce planning software for full visibility. Create schedules, track hours and assign tasks.

Not only has the amount of manual work we do been reduced, but we’re now able to optimize our processes and end up with better results.

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

Useful Resources

FAQs

DELMIA Quintiq uses powerful algorithms to analyze large amounts of data, providing valuable insights, predictions, and recommendations. This technology helps improve planning and scheduling by learning from your business, leading to a more efficient and informed supply chain, often referred to as a Self-Learning Supply Chain.

DELMIA Quintiq Workforce Scheduling revolutionizes workforce management. With integrated planning and scheduling, it ensures optimal productivity and profitability. This solution offers full visibility and control, covering everything from long-term planning to daily scheduling and real-time adjustments.

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering