Robotics

Enable Digital Continuity Between Design and Production

Robot Programming & Modeling in Production

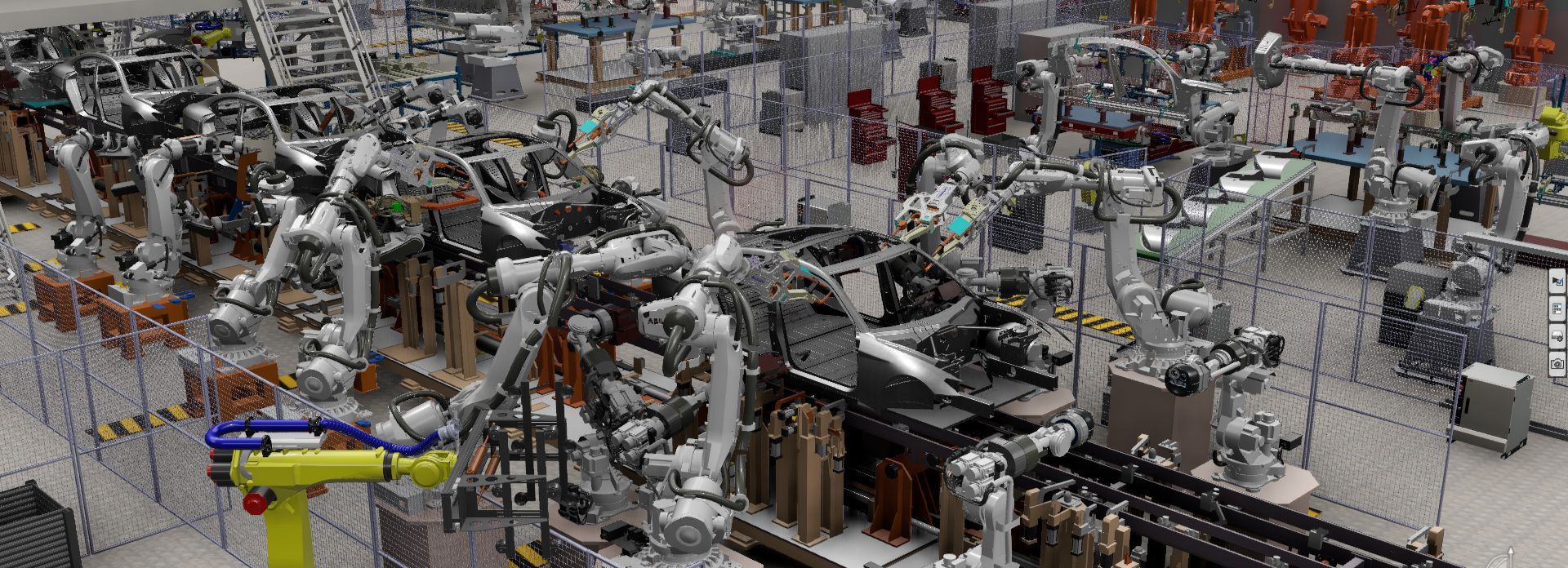

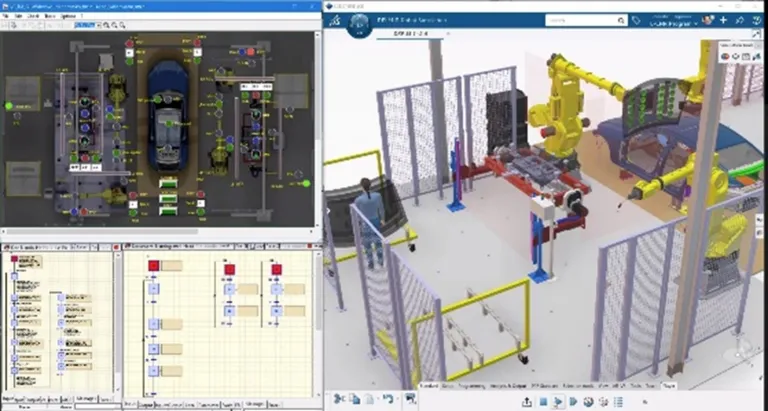

DELMIA Robotics software validates production systems and robot programming within a 3D collaborative environment. The software seamlessly integrates with CAD solutions, reflecting adjustments in real-time, leading to a streamlined workflow, minimized errors, and reduced time-to-market.

Define robotic work cells, program and optimize robots, and simulate the manufacturing environment and product flow virtually, eliminating the need for deployment of physical resources. This feature facilitates offline robot programming without disrupting production while providing accurate virtual validation using digital twin technology to save time and cost. It allows manufacturers to ramp up their systems with confidence the robots will perform as expected, while keeping production downtimes as short as possible.

Solution Capabilities

- Work Cell Design

- Spot Process Simulation

- Contour & Surface Simulation

- Robot Programming

- Virtual Commissioning

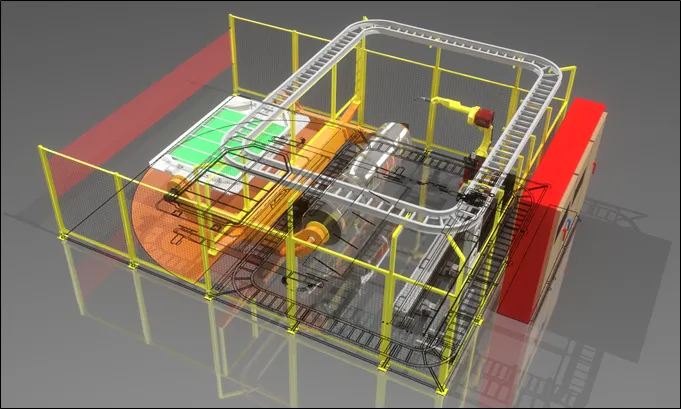

Work Cell Design

- Create, simulate, and validate tooling and equipment

- Design your work cell by importing parametric objects from catalog or by creating your own and adapt them to the required conditions

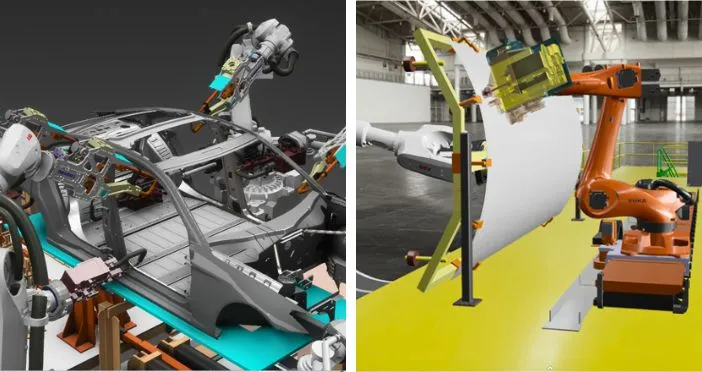

Spot Process Simulation

For Body in White and Aerospace & Defense

- Define, validate and offline program Body in White robot systems in the Virtual Factory

- Balance fasteners among multiple robots

- Create, simulate, validate and optimize drilling and riveting robot programs

- Waypoint templates to allow collision-free movement between cycles Program

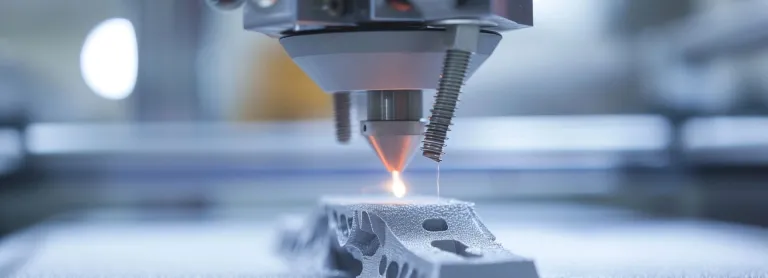

Contour & Surface Process Simulation

- Design and optimize any trajectory that is based on part intersections and contours, whether it is welding, cutting, or any other application where precise path planning is required.

- Design and optimize trajectories to achieve optimal coverage and treatment

- Manage enclosed areas, and accurately represent the actual treatment process

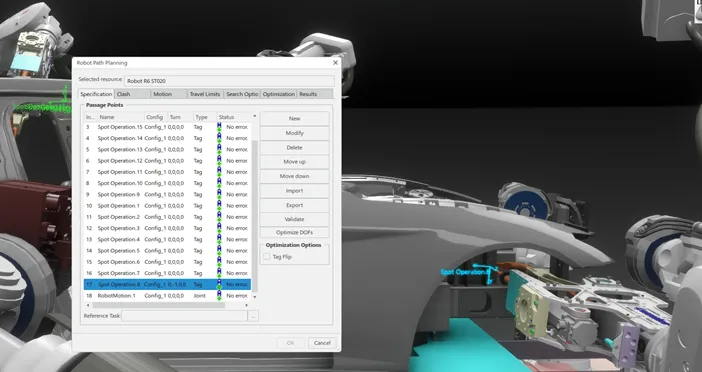

Robot Programming

- Upload and download robot programs to and from a calibrated virtual robot cell

- Translate the native robot syntax, advanced logic and IO

- Create and modify custom translators in VB.net

- Calibrate the virtual twin to match the as-built robot cell

Virtual Commissioning

- Virtually validate and fine-tune robot and PLC communication

- Communications can be connected to PLCs, the virtual robot controller, and the simulation - all in the context of the production environment

- Enable Operator virtual training on work cell operation before physical build.

- Seamless integration with automated systems through various types of connectors, including FMU, RRS-2, and specific connectors to robot virtual

With the rapid development of artificial intelligence and machine learning technologies, robot simulation, programming and modelling opened up a new horizon. Manufacturers in many industries use our software to validate robot processes such as drilling & riveting, arc welding, spot welding, material handling, paint, sealant application and shot-peening.

Key Benefits of DELMIA Robotics Software:

- Reduce time to rework due to digital continuity between design and production. Any change made to the design are automatically reflected in the process plan and the robot trajectories

- Ensure safety with collision detection and complete validation of robot operations and production processes in a virtual environment using virtual twins

- Reduce time to start production by validating production line in a virtual environment

- Collaboration inside and outside the organization with controlled data availability

DELMIA Robotics software products are packaged as Roles to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

We are now selling complete logistics solutions on DELMIA, and we’ve seen revenue in our robotics business line double in the last year alone.

DELMIA Robotics at Work

Video Gallery

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering