Assembly

Improve Manufacturing Processes with Augmented Reality Assembly Assistance

Augmented Reality Assembly Instructions on a Product

Regarding complex products with unique or variable configurations, assembly and manufacturing operations can be challenging. Unfortunately, current manufacturing processes are not always adapted to support this process, leading to long cycle times, risk of errors, difficult skills ramp-up, and a lack of traceability.

DELMIA Augmented Experience is an augmented reality-based solution that helps operators in their assembly tasks. It guides them step-by-step throughout the process thanks to 3D visualization and augmented reality technology superimposing virtual information on the real environment and displaying digital assembly instructions directly on the product.

The solution also provides a more efficient and reliable way of collecting data from field operations and ensures traceability and objective documentation of production activities.

As a result manufacturers can reach the “first time right” and improve productivity & quality of production operations.

- Replacement of Layers and Templates

- Assembly of Complex Equipment

- Assembly Assistance of Fixing Elements

- Assistance to Painting Operations

The preparatory phases using copying and templating systems (2D tracing paper drawings) to position small elements can be long and tedious with complex punching and cutting operations, and high template costs. DELMIA Augmented Experience for Assembly improves the process by replacing 2D layers with digital templates directly projected on the structure. Operators can then see where to position elements such as pins, harnesses, velcro, resistors, or structural parts, resulting in a reduction of errors and preparatory tasks in minutes instead of days.

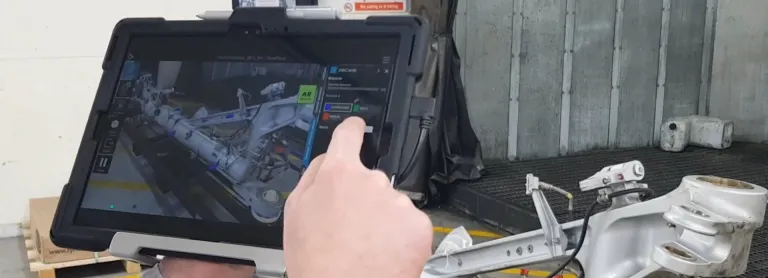

The assembly of complex equipment requires numerous and variable tasks (riveting, drilling, fastening, etc.), which are very difficult to understand for operators and can be a source of errors. Step-by-step visualization of the 3D instructions in augmented reality, directly superimposing the 3D model and the work instructions on the equipment to assemble, making it simple to use. Easy understanding of instructions for the operators, allowing a reduction of errors and faster skills ramp-up.

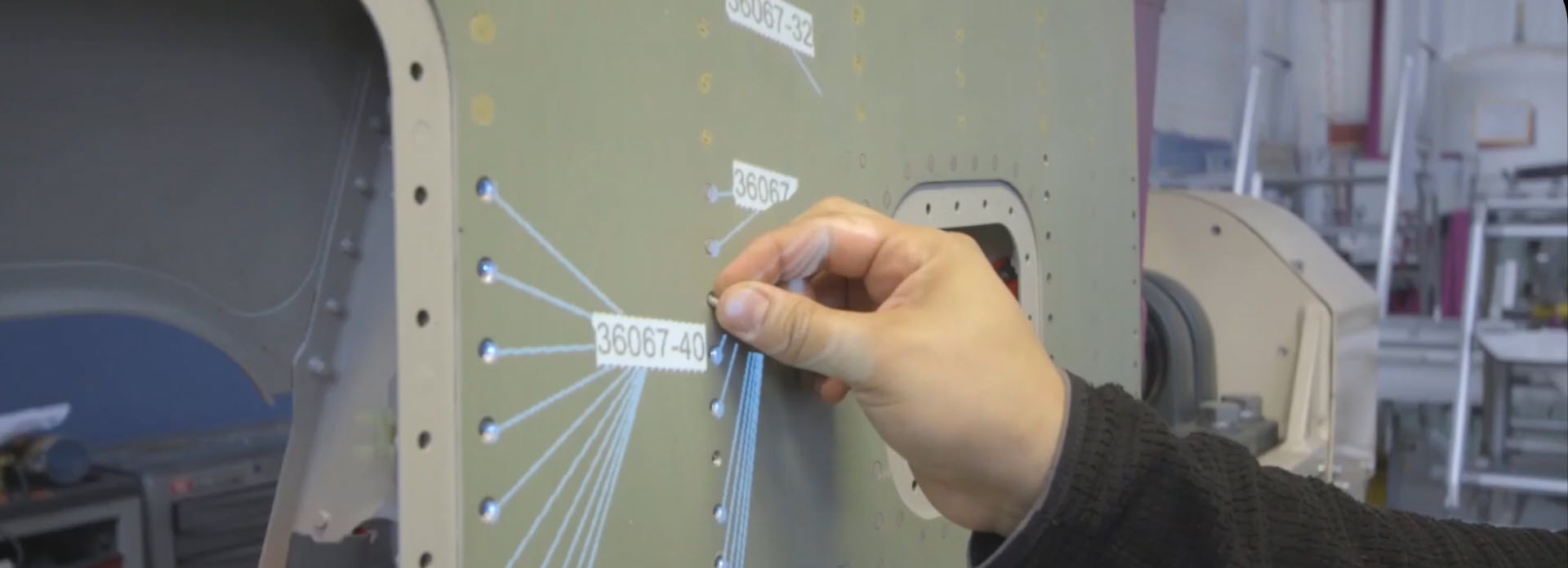

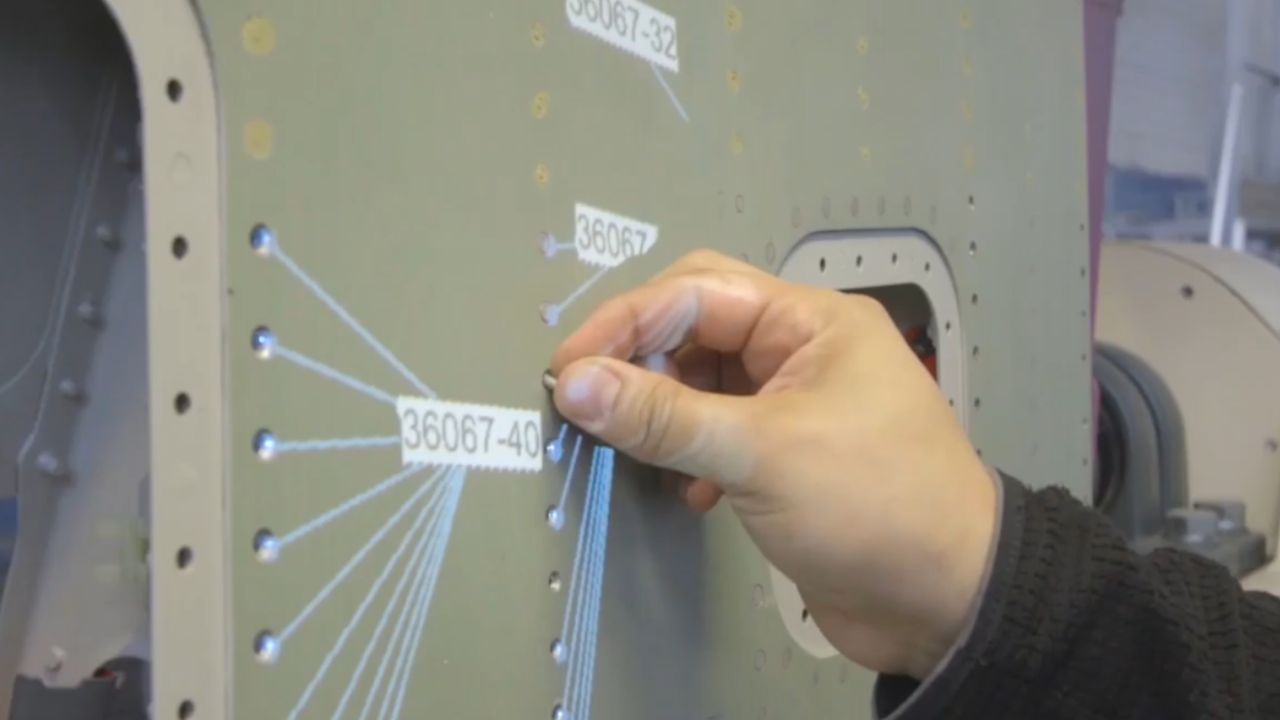

Positioning multiple fixing or connecting elements at the right place on structures subject to variable or unique configurations is complex and can lead to costly errors. Instead, the correct location and references of the elements are materialized directly on the equipment to be assembled via augmented reality, through a projection system or screen display, to guide the operator to execute tasks right the first time. This leads to improved production quality and productivity and operators’ work comfort.

To carry out painting operations on large surfaces, it is first necessary to protect certain precise zones. The preparation time is often long, and the correct identification of the masking areas and the painting zones may be difficult, yielding a high risk of errors. With DELMIA Augmented Experience for Assembly, masking and paint areas are projected directly on the surface through augmented reality to guide the operators precisely in their tasks.

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

Also Discover

FAQ about Augmented Reality for Assembly

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering