Virtual Twin for Manufacturing

Flawlessly Execute and Optimize Manufacturing Operations

Manufacture Right the First Time

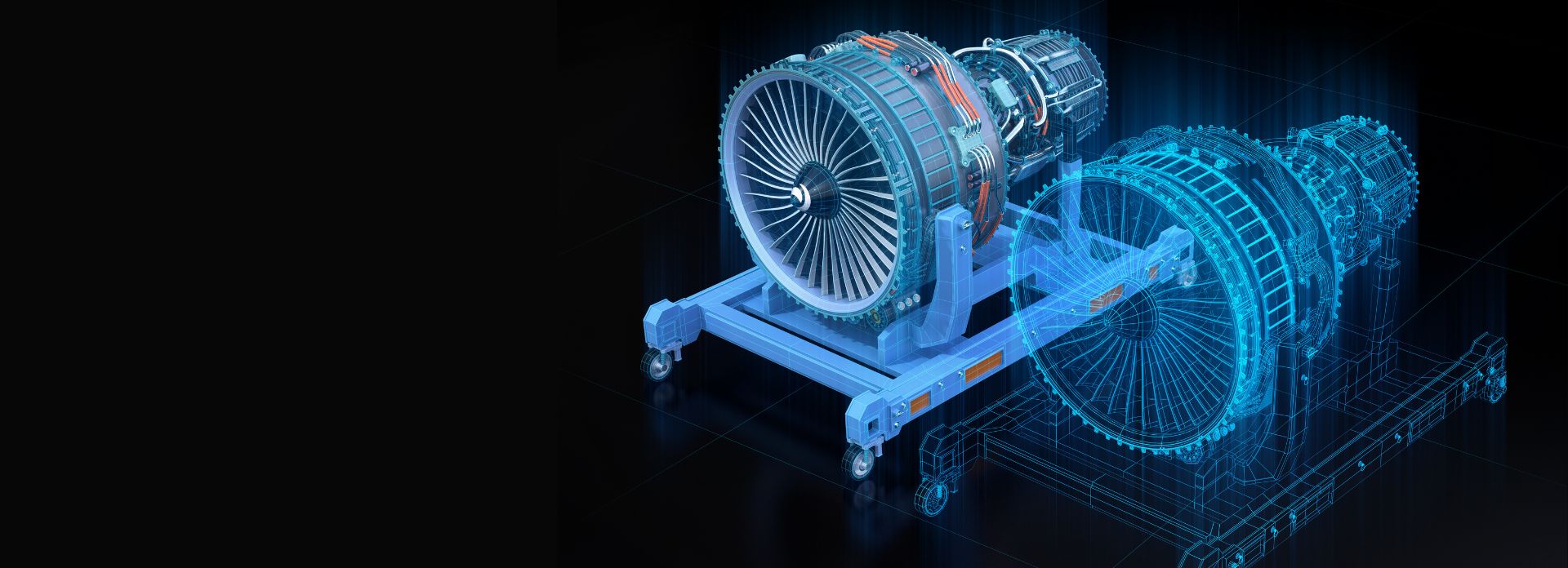

At DELMIA, we believe the virtual world improves the real world of manufacturing. Our solutions extend beyond digital twin technology to help businesses become more sustainable, innovative, safe, and profitable in producing and delivering products and services that resonate with their customers. Through a virtual twin experience, you can virtually demonstrate what can be implemented and executed in the real world through modeling, simulation and visualization--from manufacturing production, plant layout, operations, and logistics – across the entire supply chain.

Expand digital models into an actionable virtual twin that enhances processes between engineering and manufacturing—production, assembly, testing, and maintenance. Augmented reality technology and interactive 3D guides human operators in complex assembly tasks, automates quality inspections and increases worker safety and satisfaction. With the connectivity and collaboration of the 3DEXPERIENCE® platform, what-if scenarios can be created and optimized, including anticipating disruptions, new product launches, shifting production sourcing, and re-balancing workforce capacity.

DELMIA’s virtual twin experience Supports Sustainability and Profitability through:

- 3D model-based capability to represent assets, business processes, infrastructure, and metrics

- Unlimited simulation to experiment virtually and determine the best configuration in the real world

- A closed-loop connection that allows real-time updates to refine and optimize processes for a long-term strategy continuously

- Advanced manufacturing techniques and captured contextualized data

- Augmented Reality for improved process, execution, quality, and workforce productivity and satisfaction

- Model-based quality and traceability throughout manufacturing and maintenance

- Virtual design and simulation of processes and facilities to be more sustainable

- Visualization and guidance for complex product manufacturing

The virtual twin experience

DELMIA delivers the Virtual Twin for Manufacturing, going beyond the static representation of digital twins. It is a dynamic virtual model of real-world products, facilities, assets, and processes powered by real-world data, allowing manufacturers to collaborate, model, optimize and perform efficiently. Simulating outcomes of multiple scenarios in the virtual model helps manufacturers form the best plans in line with business and sustainability goals.

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA.

FAQ about Virtual Twin in Manufacturing

Unlike a digital twin prototype that focused on one specific object, virtual twin experiences let you visualize, model and simulate the entire environment of sophisticated experience.

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering