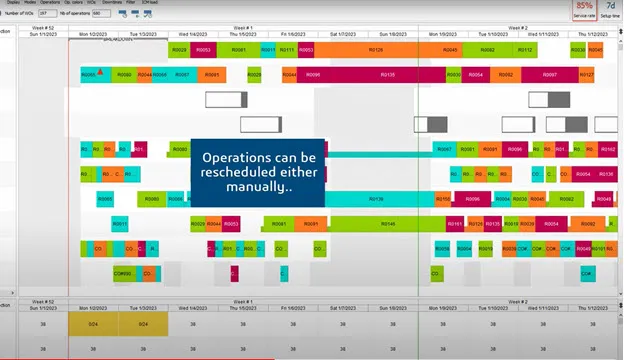

Production Scheduler

Providing Short-term Planning Optimization at Finite Capacity

Optimize Short-Term Production Scheduling

DELMIA Ortems Production Scheduler offers detailed scheduling and integrated management of product and process-related constraints across multiple resources such as machines, tools, and operators. Production Scheduler provides short-term optimization capabilities for Made-to-Order, or inventory-based production flows for manufacturers. DELMIA Ortems Production Scheduler uses its configurable optimization engine and basic criteria to improve production sequences and dispatching over the various plant resources, enabling users to reduce changeover times, raw material inventory, and work-in-process. DELMIA Ortems Production Scheduler increases manufacturing agility through improved control and responsiveness during production fluctuations and changes in demand. Collaborative features enable supply chain participants to stay engaged based on their level of responsibility, as multiple planners can work simultaneously on the same plan. Production Scheduler’s innovative, user-friendly design helps teams anticipate and control load fluctuations.

Key Benefits:

-

Decreases cycle time and WIP

-

Enhances customer service and lead-time reliability

-

Creates what-if scenarios

-

Simplifies user interfaces intuitively

-

Creates schedules faster

-

Integrates into the ERP system easily

-

Increases agility even with unexpected shop floor events

-

Improves productivity by minimizing set-up times

DELMIA Ortems is a powerful and scalable solution with an intuitive and easy to understand user interface that can evolve with us over time.

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering