Manufacturing Planner

Accurately Model Production Constraints that Reflect Shop Floor Reality

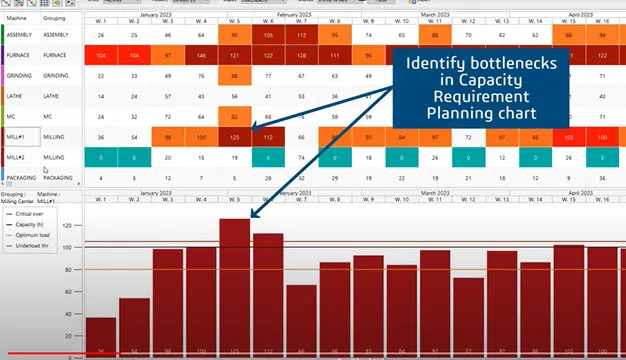

Create Reliable Capacity Plans Based on Work-Order Load

DELMIA Ortems Manufacturing Planner integrates all resources- to product-related constraints and improves manufacturers’ midterm planning processes such as Master Production Schedule (MPS). While Material Requirements Planning (MRP) generates infinite capacity requirements, Manufacturing Planner matches the Work-Order (WO) load with capacity and due dates to propose finite capacity planning. Manufacturing Planner provides load analysis views to identify manufacturing bottlenecks across all primary and secondary resources immediately. Run what-if simulations with its rich, interactive tools allowing for schedule modifications and what-if simulations to quickly respond to production contingencies, capacity issues, and changes in customer demand across internal and subcontractor resources. DELMIA Ortems Manufacturing Planner software helps users anticipate and control load fluctuations. The collaborative and innovative features enable supply chain participants to stay engaged based on their level of responsibility. In addition, planning and Key Performance Indicators (KPI) data are shared with partners, customers, subcontractors, and suppliers across the organization.

Key Benefits:

-

Improves customer due date fulfillment and level of service

-

Anticipates and control load fluctuations

-

Synchronizes production between production areas

-

Reduces inventory and cycle time

-

Re-synchronizes flow lines in case of contingencies

-

Integrates easily into other Enterprise Resource Planning (ERP) systems

-

Reduces time to a finite capacity planning

-

Minimizes production disruptions with contingency planning

DELMIA has helped us reduce our stock by 27%, increase our productivity by 18% and reduce waste by 35%.

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering