DELMIA Ortems

Balance and Solve Operational and Planning Issues

What is DELMIA Ortems?

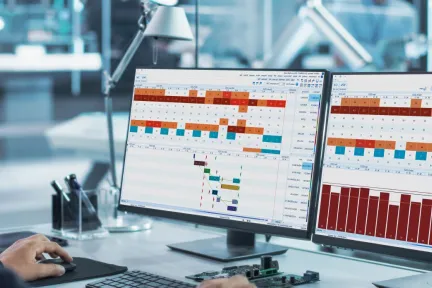

DELMIA Ortems offers solutions for agile planning, scheduling and production. It takes traditional Manufacturing Execution Systems (MES) to the next level, adding the power of constraint-based, finite-capacity resource optimization and synchronization of production flows. Manufacturers can optimize the utilization of available resources while accounting for daily issues to improve service delivery. This agile, highly responsive solution helps manufacturers and planners balance and solve operational issues between supply and demand, thus enabling seamless process integration and visibility to demand, supply and operations. Users can quickly identify manufacturing bottlenecks, schedule modifications, and what-if simulations to improve Detailed scheduling and Master Production Scheduling (MPS) processes.

The software boosts responsiveness and visibility, aiming to cut cycle times, trim down inventory, and enhance lead-time. It achieves this through advanced planning and scheduling, which excels in quickly optimizing complex production challenges. The solution minimizes manual work and errors for planners by providing accurate schedules, considering finite capacity, and supporting dynamic short-term scheduling and rescheduling. This agile decision support leads to synchronized production flows, shorter lead times, and increased production rates, ultimately improving operational efficiency and manufacturing excellence.

Its advanced planning and scheduling software complements DELMIA Industrial Engineering and DELMIA Apriso by providing comprehensive digital continuity with artificial intelligence-driven decision support across all manufacturing and production aspects — from raw materials to finished products.

Benefits of DELMIA Ortems

Reduced Lead Times

By streamlining production planning and scheduling, DELMIA Ortems helps in reducing lead times, enabling organizations to respond more quickly to customer demands and market changes.

Accurate Scheduling

The software's ability to create accurate and realistic schedules contributes to improve on-time delivery performance.

This is crucial for maintaining customer satisfaction and meeting contractual commitments.

One Centralized Platform

The software provides a centralized platform for planning and scheduling, offering increased visibility into the entire production process.

This visibility is essential for making informed decisions and continuous improvement.

Key Features of DELMIA Ortems

- Advanced Planning

The software assists in long-term planning, considering factors such as production capacity, resource availability, and demand forecasts. - Finite Capacity Scheduling

It helps in creating detailed schedules that consider the finite capacity of production resources, such as machines and labor. - Real-Time Monitoring

DELMIA Ortems often provides real-time monitoring capabilities, allowing users to track the progress of production orders and adjust as needed. - Scenario Analysis

Users can perform "what-if" analysis to simulate different scenarios and understand the impact on production schedules. - Integration

It can integrate with other enterprise systems, such as Enterprise Resource Planning (ERP) systems, to ensure seamless data flow between different parts of the organization. - Optimization Algorithms

The software typically incorporates optimization algorithms to find the most efficient and cost-effective production schedules.

DELMIA Ortems Solutions

During the COVID-19 pandemic, we had an unexpected and extremely important need: to double production for our machines for making masks. We had to quickly convert our production equipment to produce double the quantity in a very short amount of time. Without DELMIA Ortems, this planning would not have been possible

Start Your Journey

Useful Resources

FAQs

In the short term, our software will help you optimize the production processes and operations of your business while taking into account limited capacities. On top of that, DELMIA Ortems will enable your organization to create a smooth production plan synchronized with material planning.

In the long term, DELMIA Ortems solutions will make it possible for your business to accurately forecast the amount of required resources and investment based on thorough capacity analysis.

DELMIA Ortems solutions help optimize production planning & scheduling for the customers all over the globe. You can find plenty of customer success stories and videos on customer stories page, but here are some of our favorites:

- Agile planning for Ortakçı Glass which resulted in 40% increase in customer service levels

- Planning tool integration for Elidose which enabled them to anticipate seasonality and adjust resources accordingly

- Advanced planning & scheduling for Altaïr Group which granted them the ability to accurately anticipate demand for their products

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering