Manufacturing Software to Optimize Production Management

Manufacturing software has revolutionized production processes, enhancing efficiency and driving growth for businesses of all sizes.

What Is Manufacturing Software?

Manufacturing software is more than a system—it’s a strategic enabler. It connects teams, streamlines operations and supports decision-making across the product lifecycle. Designed to improve how businesses create, operate and continuously improve their end-products, it helps transform ideas into high-performing, sustainable results.

By integrating tools for planning, real-time monitoring, supply chain coordination and quality control, it enhances efficiency, reduces waste and accelerates time-to-market in a digital and competitive manufacturing environment.

Key Benefits of Manufacturing Software

Improved Productivity & Efficiency

Manufacturing software significantly boosts productivity by automating repetitive tasks and optimizing workflows. It enables real-time monitoring of production processes, allowing for quick identification and resolution of bottlenecks.

Enhanced Inventory Management

Gain real-time visibility into stock levels, automate reordering, and avoid overstock or stockouts. Smarter inventory management reduces costs, improves efficiency, and strengthens cash flow.

Streamlined Production Planning

Manufacturing software facilitates accurate production scheduling and resource allocation. It considers factors such as demand forecasts, available resources and production capacities to create optimized production plans.

Cost Reduction & Optimization

Manufacturing software helps businesses identify areas for cost reduction and optimization by streamlining processes and providing better operational visibility. It can help optimize resource utilization, leading to significant cost savings.

Manufacturing Software & Sustainability

Harnessing technology for greener manufacturing.

Driving Sustainable Production Practices

Manufacturing software supports sustainable production by optimizing energy use, minimizing waste and enabling life cycle assessments. It empowers businesses to reduce environmental impact while designing and producing smarter end-products.

By integrating data-driven insights and automation, it helps manufacturers make informed decisions that balance productivity with environmental responsibility. As industries strive for net-zero goals, these digital solutions are essential for building a more sustainable future.

With the virtual twin experience and the collaborative platform, companies can experiment and then apply circular design principles to the product at every step [...] The results? Well, you cut down on waste and reduce the environmental impact of the product as it moves along the supply chain and the whole value network.

Main Functions of Manufacturing Software

Learn more about practical applications of manufacturing software and how to boost efficiency with integrated manufacturing capabilities.

Production planning & scheduling

Optimize workflows with automated scheduling and resource allocation to reduce downtime and ensure on-time production.

Supply chain & inventory management

Improve material tracking and forecasting to reduce waste, prevent stockouts and streamline procurement for just-in-time manufacturing.

Quality control & compliance

Implement real-time monitoring and defect detection to meet regulatory standards and enhance product consistency.

Production monitoring & optimization

Utilize data-driven insights to enhance machine efficiency, identify bottlenecks and improve productivity.

Collaboration & data integration

Unify teams across departments with centralized digital tools to ensure seamless communication and decision-making.

Our Manufacturing Solutions Drive Innovation Across Industries

From autonomous vehicles to personal electronics, today's manufactured products are smarter, more complex and more sustainable. At Dassault Systèmes, we don’t just support industries — we empower the creation and continuous improvement of the end-products that define them.

The Five Shifts Shaping the Future of Manufacturing

Manufacturing is no longer just about making things—it’s about creating connected, circular and adaptive systems. Here’s how the industry is transforming:

1. From linear to circular

Sustainability isn’t optional. Manufacturers are embracing circularity to reduce waste, reuse resources and rethink product lifecycles.

2. From supply chains to value networks

Resilience is the new efficiency. Agile, multi-node ecosystems are replacing rigid, centralized supply chains.

3. From centralized to sovereign

Manufacturing is moving closer to customers and closer to control—with flexible, automated and sovereign production capabilities.

4. From one-time products to living experiences

Products don’t end at delivery. Manufacturers now create evolving experiences that grow smarter over time.

5. From job roles to skills journeys

Lifelong learning is essential. New technologies demand new skills—and the ability to adapt, learn and lead through change.

Manufacturing Software for Different Production Needs

Small & Medium-Sized Enterprises (SMEs)

SMEs use Enterprise Resource Planning (ERP) and inventory management software to automate production, track materials and enhance efficiency. These tools help optimize workflows, reduce costs and improve customer service, allowing SMEs to compete with larger enterprises.

Large-Scale Manufacturing Operations

For large manufacturers, Manufacturing Execution System (MES) and MOM (Manufacturing Operation Management) software ensure multi-site coordination, supply chain optimization and real-time data analytics. These solutions streamline production and maintain quality consistency across global operations.

Custom & Made-to-Order Production

Custom manufacturing relies on ERP and Computer-Aided Manufacturing (CAM) software for flexible scheduling, cost estimation and managing complex configurations. These tools support businesses in delivering personalized products efficiently.

Batch & Process Manufacturing

Industries like food, beverage and pharmaceuticals use MES and Entreprise Requirements Planning (MEP) solutions for recipe management, regulatory compliance and quality control. These systems track ingredients, optimize production and maintain batch consistency.

Transforming Production with Dassault Systèmes' Manufacturing Solutions

Unlock the power of digital manufacturing to optimize processes, improve collaboration and enhance efficiency at every stage of production.

Optimize digital manufacturing with DELMIA

DELMIA orchestrates and optimizes your production systems with powerful tools for virtual manufacturing, real-time operations and supply chain planning.

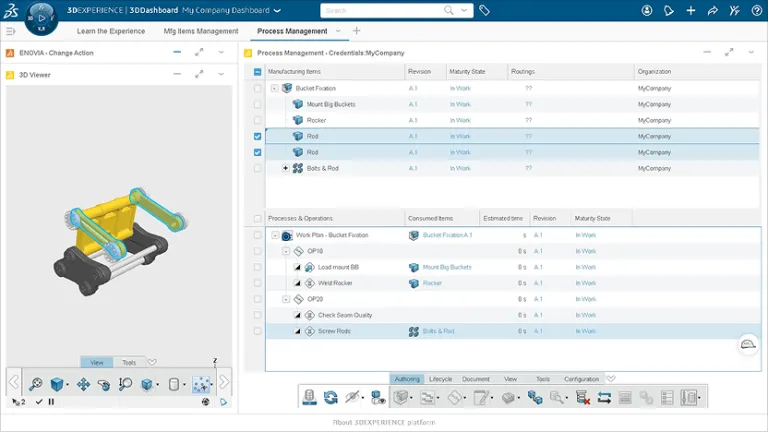

Enable seamless collaboration with ENOVIA

ENOVIA enables seamless collaboration with centralized Product Lifecycle Management (PLM), connecting engineering, manufacturing and business teams.

Leverage real-time intelligence with NETVIBES

NETVIBES harnesses real-time data intelligence and dashboards to drive agile decision-making and monitor key manufacturing KPIs.

Engineer with precision with CATIA, Design smarter with SOLIDWORKS

CATIA and SOLIDWORKS provide powerful tools for 3D design, mechanical modeling and assembly management. They help teams innovate faster and deliver optimized products from the first iteration.

Simulate with confidence using SIMULIA

SIMULIA enables high-performance simulation to predict product behavior before manufacturing. It helps reduce risk, improve quality and accelerate development.

Enhance customer engagement with 3DEXCITE

Create immersive product experiences to support marketing, sales and digital twin validation—bridging the gap between concept and customer engagement.

Advance scientific manufacturing with BIOVIA

BIOVIA supports life sciences manufacturing with powerful tools for formulation, lab management and regulatory compliance. It ensures digital continuity from R&D to production for greater efficiency and quality control.

Streamline clinical operations with MEDIDATA

MEDIDATA connects clinical and manufacturing data to optimize batch production, ensure compliance and accelerate time-to-market for life sciences companies.

A connected manufacturing ecosystem

The 3DEXPERIENCE platform brings together all of Dassault Systèmes’ manufacturing capabilities into a unified ecosystem. This ensures continuity, collaboration and performance throughout the end-product lifecycle.

Our Customers' Experience with Our Manufacturing Software

Manufacturing Concepts & Technologies

Lean Manufacturing

Streamline operations by applying Lean Manufacturing principles that reduce waste, improve process flow and enhance agility. Real-time production data helps identify inefficiencies and drive continuous improvement. DELMIA enables digital work instructions, synchronized planning and responsive shop floor execution—boosting throughput and cutting resource usage.

ERP & MRP

Connect ERP and MRP systems to gain full visibility and control over your manufacturing lifecycle. From inventory and procurement to scheduling and cost tracking, unified planning improves responsiveness and efficiency. Dassault Systèmes solutions align design, engineering and operations—optimizing production while reducing waste and costs.

Additive Manufacturing

Optimize your additive manufacturing workflow from design to production. SIMULIA enables simulation of material behavior, part optimization and thermal effects during printing. DELMIA supports planning, machine programming and estimating cost, time and material usage—reducing waste and accelerating time-to-market.

Design for Manufacturing

Optimize product development by embedding manufacturability insights early in the design process. CATIA helps identify constraints and improve geometries for machining, assembly, or additive manufacturing. This ensures designs are cost-effective, production-ready and reduce time-to-market by avoiding late-stage rework.

Virtual Twins for End-to-End Optimization

Imagine being able to test your factory before it’s built. Predict supply chain issues before they happen. Improve your product before it exists. That’s the power of Virtual Twins.

At Dassault Systèmes, we bring Virtual Twin Experiences to life across three dimensions:

Virtual twin of a product

Simulate, analyze and optimize the behavior and lifecycle of a physical product through a scientific digital replica that evolves with real-world data—enabling smarter decisions and improved performance.

Virtual twin of a production system

Model, simulate and optimize end-to-end production systems as dynamic, data-driven ecosystems. Integrate processes, supply chains, resources and operations to test scenarios, improve performance and support agile, sustainable decision-making.

Virtual twin of an organization

Visualize, analyze and steer your organization as a dynamic system of systems. Connect value networks, simulate future scenarios and uncover strategic opportunities to boost resilience and business performance.

Manufacturing Education to Empower Professionals & Academics

Dassault Systèmes offers comprehensive educational resources and programs designed to equip professionals and students with the skills needed in modern manufacturing.

These include learning libraries with skill development courses for professionals, which help them stay current with the latest industry practices and technologies.

For academic institutions, Dassault Systèmes provides access to the 3DEXPERIENCE platform, offering students hands-on experience with advanced manufacturing tools and simulations.

Why Choose Dassault Systèmes' Manufacturing Software?

Innovation-driven solutions

Dassault Systèmes focuses on developing cutting-edge manufacturing solutions. These innovations drive industries forward.

Seamless collaboration

The company's platform facilitates seamless collaboration across departments and organizations. This approach boosts productivity and innovation.

Industry-specific expertise

Dassault Systèmes offers tailored solutions for various industries. This expertise ensures optimal performance across diverse manufacturing environments.

Scalability & flexibility

Our solutions are designed to grow with businesses. This scalability supports companies of all sizes and stages.

Sustainability focus

Dassault Systèmes prioritizes sustainable manufacturing practices. The solutions help reduce environmental impact and promote responsible production.

Want to Go Further?

Explore the content below to learn more about Dassault Systèmes and Manufacturing Software.

Get in Touch with Our Experts

Fill in the form to have a Dassault Systèmes expert contact you to answer your questions and discuss any of your needs.

Let’s transform your Manufacturing Software journey together—contact us today!