Defense Aircraft Design

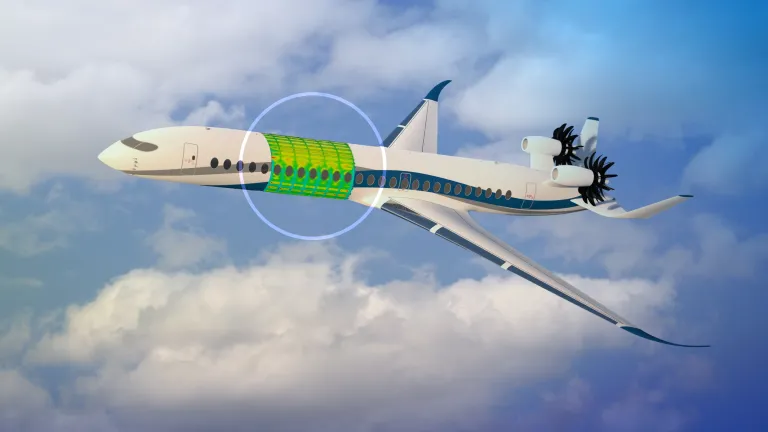

Optimize defense aircraft design, achieve advanced stealth, aerodynamics, and structural integrity through high-fidelity simulations with SIMULIA solutions.

Advanced Simulation for Defense Aircraft

Defense aircraft face extreme conditions, requiring advanced stealth, aerodynamics, and structural integrity. SIMULIA provides the tools to meet these demands, offering nonlinear structural simulation with Abaqus for resilience, aerodynamic insights into shocks and flow dynamics with PowerFLOW, and electromagnetic simulation for radar and antennas with CST Studio Suite.

Integrated on the 3DEXPERIENCE platform, SIMULIA ensures traceability across processes, accelerates innovation, and supports smarter, more robust system designs through Model-Based Systems Engineering (MBSE).

Key Benefits of SIMULIA Defense Aircraft Design Solutions

Multiphysics Simulation Capabilities

Enhance prediction accuracy through automated coupling of structural, aerodynamic and electromagnetic simulations

Reduced Physical Testing

Enhance certification confidence by enabling Certification by Analysis

Simulation Empowered MBSE

De-risk program proposals by enhancing CATIA Magic System Models with advanced simulations

Advanced Simulation Capabilities

Defense Systems are characterized by extreme operational requirements – SIMULIA provides the most advanced non-linear simulation capabilities required for these system

SIMULIA Customers in Defense Aircraft Design

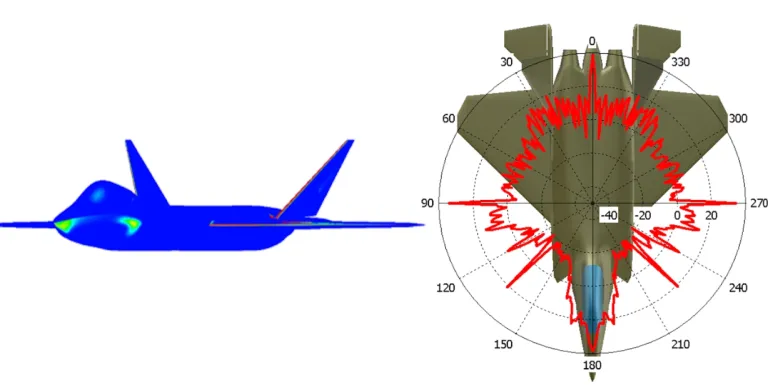

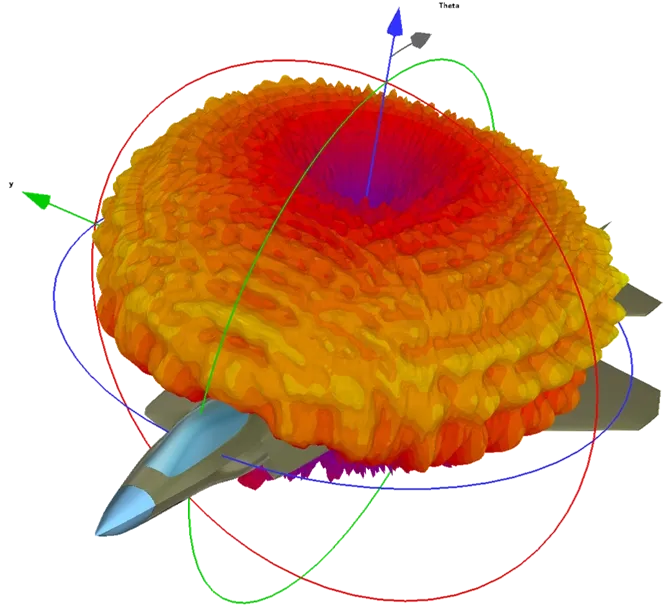

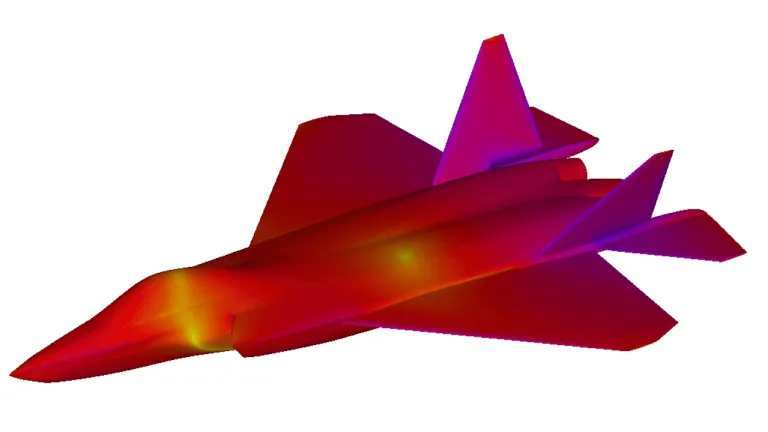

Radar Signature Analysis

Unlock next-level stealth with CST Studio Suite®.

Analyze and optimize Radar Cross Section (RCS) with 3D electromagnetic simulation, replacing costly physical tests. From the earliest stages of designing military aircraft, drones, or missiles, gain unmatched insight into radar detectability.

- Advanced diagnostics—High Resolution Range Profiles, sinograms, hotspots, Inverse Synthetic Aperture Radar,

- Ray visualization—reveal hidden patterns and vulnerabilities.

- Simulate and perfect radar-absorbent paints, frequency-selective surfaces, and cutting-edge metasurfaces with precision and confidence.

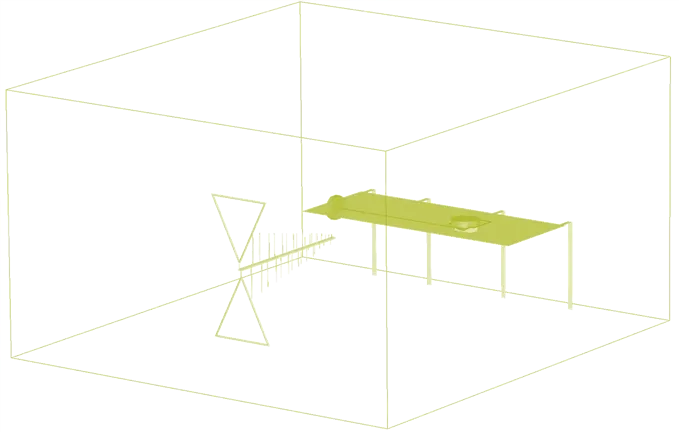

Mission Success with Advanced Vibro-Acoustic Simulation

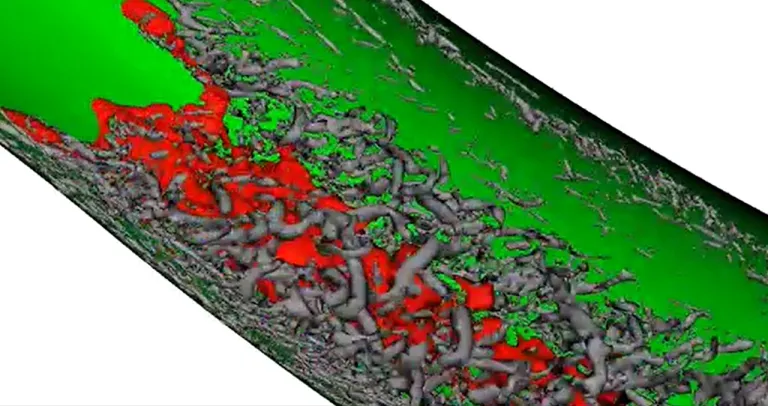

Military aircraft must withstand extreme vibrations and unsteady aerodynamic loads that threaten structural integrity, avionics reliability, and crew safety. Failure to address these risks can compromise performance and mission readiness.

With SIMULIA PowerFLOW and Wave6, engineers gain high-fidelity vibro-acoustic simulation to accurately predict complex aero-vibro-acoustic interactions caused by highly unsteady external flows. This integrated solution enables design improvements, risk mitigation, and enhanced equipment performance—while replacing expensive and time-consuming wind-tunnel tests to provide aerodynamic loads with high-fidelity PowerFLOW simulations.

From airframe durability to pilot safety, SIMULIA delivers the precision and insight required for mission-critical defense applications.

Simulation Empowered MBSE

The adoption of Model-Based Systems Engineering (MBSE) is accelerating as Defense organizations and their supply chains face increasingly complex requirements.

CATIA Magic, integrated with the 3DEXPERIENCE platform, delivers a unified environment for defining, simulating, and qualifying systems across all engineering milestones. This model-centric approach enables early trade-off of alternatives, automated simulation to increase confidence in design choices, reduced risk in concept phases, and higher fidelity through multi-domain integration.

Extended with SIMULIA high-fidelity simulation tools, MBSE models can incorporate detailed structural, thermal, and multi-physics analyses to validate performance under real-world conditions. Together, CATIA Magic, SIMULIA, and the 3DEXPERIENCE platform provide a scalable framework for rigorous, traceable, and efficient systems engineering.

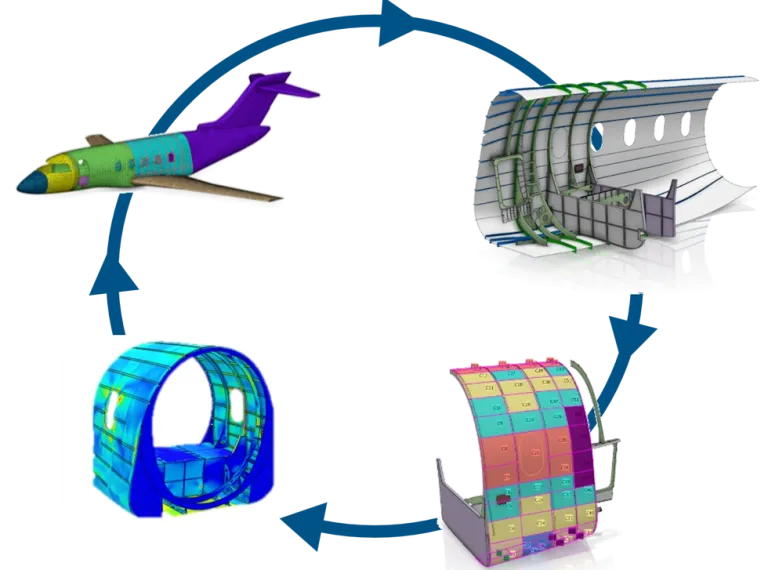

MODSIM on the 3DEXPERIENCE Platform: Unifying Modeling and Simulation

Modern defense systems are evolving rapidly under the pressures of digitalization, requiring faster, more collaborative, and more resilient product development. Digital modeling and simulation now extend across disciplines—from design and analysis to procurement, manufacturing, testing, sustainment, and beyond—demanding a unified approach.

MODSIM (Modeling and Simulation), powered by the 3DEXPERIENCE platform, integrates modeling and simulation within a single environment to connect data, teams, and processes. By replacing linear, sequential workflows with cyclical, collaborative ones, MODSIM enables true concurrency and simulation-driven design. A single source of truth links evolving requirements, real-time design iterations, and high-fidelity simulation in a collaborative context.

The result: faster innovation, reduced risk, and more effective defense systems engineered with precision and confidence.

Simulation Governance and Data Management

Simulation Process and Data Management

Defense systems demand high performance and reliability, generating vast simulation data that must be managed effectively. The 3DEXPERIENCE platform streamlines SPDM by:

- Unifying data with project management.

- Ensuring traceability and compliance.

- Enabling collaboration and reducing uncertainty.

- Optimizing workflows for faster mission readiness.

SPDM ensures efficient, reliable, and scalable simulations.

Simulation Governance and Model Management

As simulation tools grow in scale and complexity, managing multidisciplinary interdependencies and diverse data threads requires advanced solutions. The 3DEXPERIENCE platform enhances simulation governance by:

- Managing content lifecycles and relationships.

- Supporting physical and virtual test campaigns.

- Aligning with ISO 10303-243 (MoSSEC framework) for improved traceability and collaboration.

This ensures better decision-making and streamlined workflows.

Workflows for Defense Aircraft Design

Aerodynamics

Defense Aircraft Aerodynamics

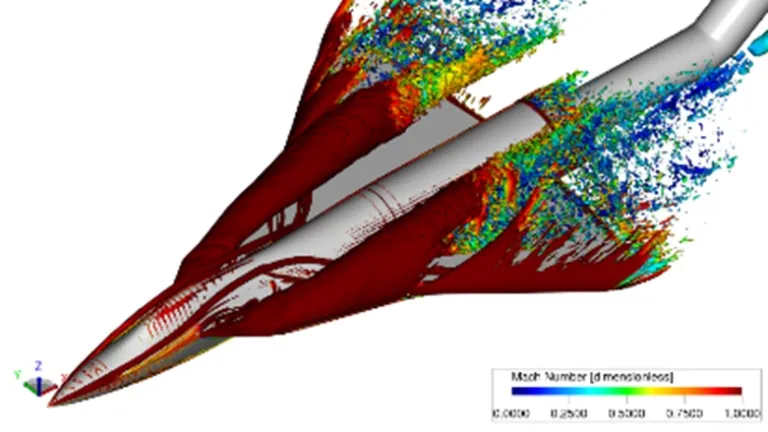

Meeting the Demands of Extreme Flight Conditions

Defense aircraft operate in extreme conditions with larger, more demanding flight envelopes than civil aircraft. While airliners encounter flow separation and shock-boundary layer interactions at the edges of their performance, these phenomena are routine for defense aircraft and often lead to complex or novel designs.

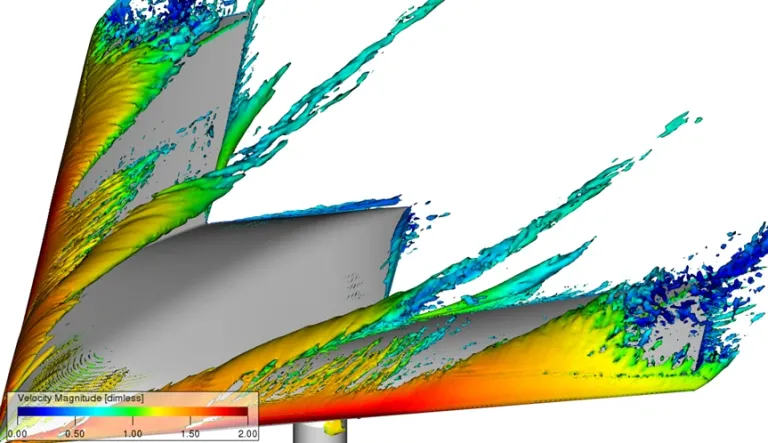

PowerFLOW excels in addressing defense aircraft challenges:

- Delivers accurate transient simulations with unsteady formulation.

- Handles massive flow separations and complex interactions around external payloads.

- Accurately predicts stall and transonic buffet

- Delivers stability and control predictions for demanding flight conditions and extreme maneuvers

Stability & Control

Stability and control are critical for military aircraft, which face demanding flight conditions such as extreme maneuvers and high angles of attack. PowerFLOW delivers high-fidelity results, enabling precise analysis of aerodynamic stability and control characteristics to ensure optimal performance and safety in challenging scenarios.

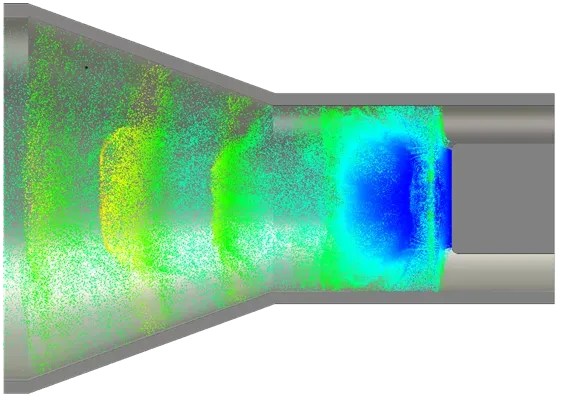

Propulsion Aerodynamics and Cavity flows

PowerFLOW offers proven capabilities to predict and reduce distortions of engine inlet flows under demanding flight conditions.

Similarly cavity flows and store separation scenarios – which generally generate highly transient flow conditions – can be accurately handled with PowerFLOW.

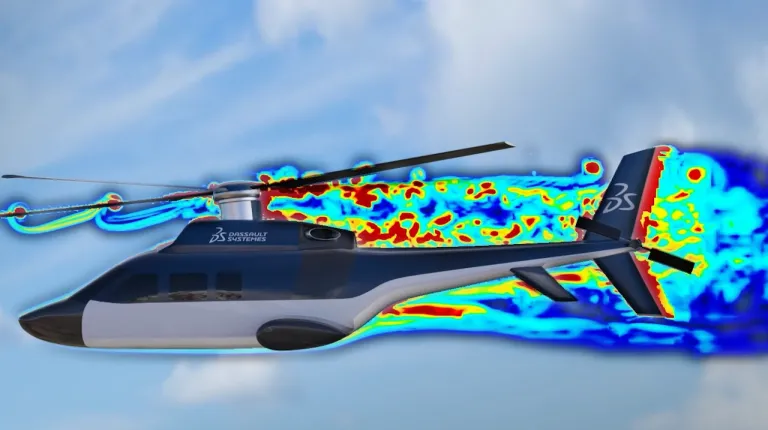

Rotorcraft Aerodynamics

Rotorcraft – both manned and unmanned – play a critical role in ensuring mission success. PowerFLOW particularly excels in accurately predicting the highly unsteady flow conditions of rotorcraft to optimize both aerodynamic and noise performance, including:

- Unsteady rotor aerodynamics

- Tail rotor shake

- Blade vortex interaction noise

- Exhaust ingestion

- Downwash and brownout

Electromagnetics

With SIMULIA’s electromagnetic and multiphysics simulation solutions, we drive the development of next-generation defense systems on land, at sea, in the air, and in space. Our workflows cover Communication, Navigation & Detection, Electromagnetic Environmental Effects (E3), EMC of equipment and subsystems, and Electromagnetic Warfare. By combining high-fidelity electromagnetic simulation with multiphysics simulation, we enable robust system design and reliable performance. Emerging players benefit from faster innovation and reduced barriers to entry, while established corporations achieve system-level optimization, streamlined certification, and significant cost savings at scale.

E3 Analysis and Mitigation of Defense Systems

Protecting defense systems from electromagnetic threats is critical for mission success. CST Studio Suite’s EM simulation capabilities, spanning time and frequency domains, enable early vulnerability detection, risk mitigation, and shielding against the full spectrum of E3 effects, while ensuring compliance with standards like MIL-STD-464D and NATO AECTP-500.

- Comprehensive Coverage: EMC, EMI, EMV, EMP, EP, ESD, and RADHAZ (HERP, HERO, HERF).

- Applications: RF systems, ultra-wideband devices, high-power microwave systems, lightning, and precipitation static (p-static).

- Key Benefits: Secure, reliable, and mission-ready military forces, equipment, and systems.

EMC Analysis and Mitigation of Defense Subsystems and Equipment

Electromagnetic (EM) simulation is essential for defense subsystems operating in harsh EM environments across land, sea, air, and space. While compliance with standards like MIL-STD-461G and NATO STANAG 4370 is not mandatory, it is crucial for ensuring performance, safety, and interoperability.

- CST Studio Suite with EMC Wizard: Simplifies virtual EMC testing with automated setup and advanced post-processing.

- Key Benefits:

- Early identification of emissions and susceptibility issues.

- Optimized subsystem designs with fewer costly iterations.

- Reduced certification risks and faster mission readiness.

Electromagnetic Warfare Component Design

Electromagnetic warfare (EMW) leverages the electromagnetic spectrum and directed energy to control, deny, or exploit it—disrupting enemies while ensuring access for friendly forces across land, sea, air, and space.

- SIMULIA’s Electromagnetic and Multiphysics Solutions: Enable the design and optimization of EMW hardware through integrated workflows.

- Capabilities Include:

- Linking electromagnetic analysis with thermal and structural effects.

- Accelerating development of antennas, high-power microwave sources, and EMC/EMI measures like shielding, filters, grounding, and transient protection.

- Benefits: Reduced prototyping, shorter design cycles, and resilient system performance in spectrum-contested environments.

Structural Analysis

Strength and Integrity Analysis

Aircraft structural design and validation require accurate prediction and evaluation of strength and durability under flight and ground load conditions. Finite Element Analysis remains the industry standard for resolving internal load redistribution, forecasting strength, evaluating damage tolerance, and predicting stress and strain responses.

- Abaqus and 3DEXPERIENCE Workflows: Deliver solutions for both linear and non-linear analysis.

- Key Capabilities:

- Extensive material models and at-scale fastener ideation.

- Best-in-class modeling of mechanical interactions.

- Techniques like unitary load case superposition, sub-structuring, and VCCT for comprehensive strength and durability assessments.

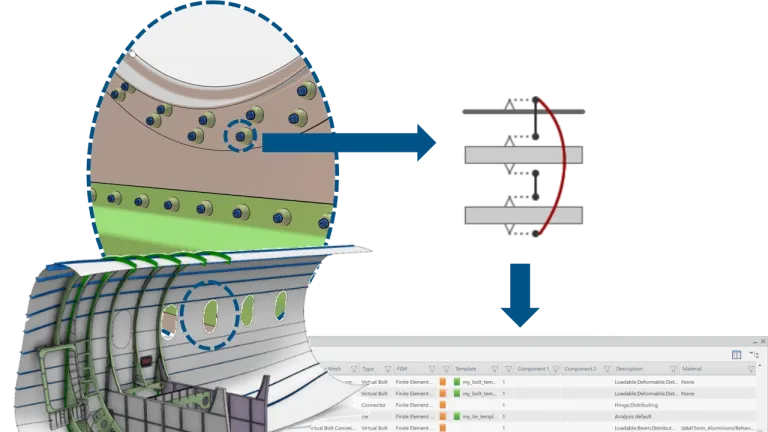

Aerospace Fasteners & Mechanically Fastened Connections

Analysis of mechanically fastened connections in aerospace structures requires automation and ideation to balance scale with predictive accuracy. Finite element analysis remains the dominant technique for strength and integrity predictions.

- Point and Assembled Fastener Technology in Abaqus: Sets the industry benchmark for fastener modeling and analysis.

- 3DEXPERIENCE Platform: Enhances MODSIM capabilities with:

- Automation, design traceability, and associativity.

- Fastener locations and simulation attributes driven by upstream design specifications.

- Management of multiple fastener ideations to meet varying analysis requirements.

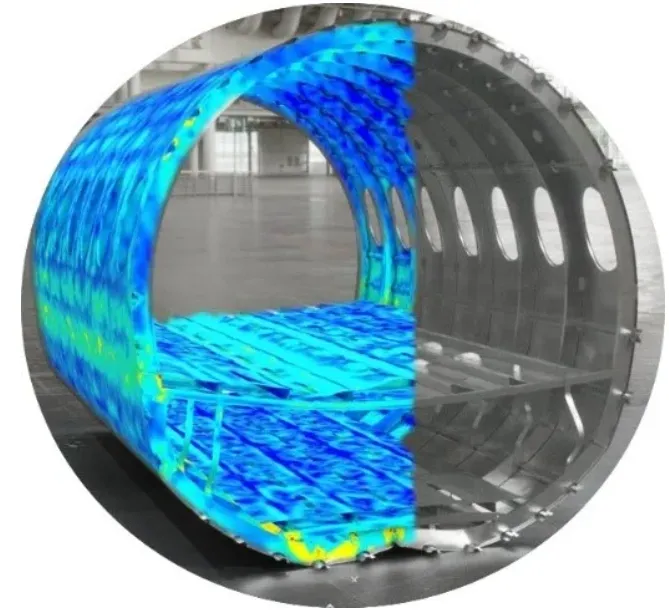

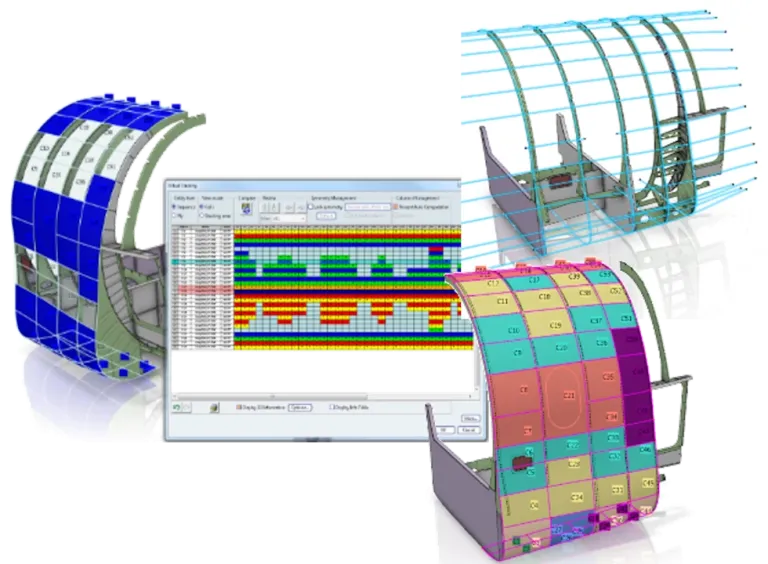

Composite Materials & Structures

The drive for lightweight aerospace structures has increased the use of composites, requiring careful integration of manufacturability and performance. Early design phases benefit from efficient macroscopic ideations, with higher model fidelity introduced as designs mature.

- Abaqus and Abaqus/CAE: Provide robust simulation for layered and non-layered composites, addressing non-linearity, advanced failure criteria, and delamination.

- Composites Modeler for Abaqus/CAE: Enhances ply modeling, ensures manufacturable designs, and integrates analysis, design, and manufacturing.

- 3DEXPERIENCE Platform: Elevates MODSIM capabilities with multidisciplinary integration, design traceability, and reuse. It supports:

- Seamless consumption of composite design data from CATIA.

- Exploration and sizing of composite cell arrangements for initial design proposals.

Industry Processes for Defense Aircraft Design

Start Your Journey

The world of Defense Aircraft Design is changing. Discover how to stay a step ahead with SIMULIA.

FAQs about Defense Aircraft Design

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering