SIMULIA Industrial Equipment Solutions

Optimize design and performance with SIMULIA's Industrial Equipment solutions. Enhance efficiency, safety, and cost-effectiveness in manufacturing.

Lead The 4th Industrial Revolution with SIMULIA’s Industrial Equipment Engineering Solutions

Industrial Equipment manufacturers make some of the most complex products in the world under highly competitive market conditions. Products are specialized and have demanding design and production requirements. Manufacturers face the challenges of creating products that meet many different customers' performance and safety requirements while improving cycle times and reducing costs.

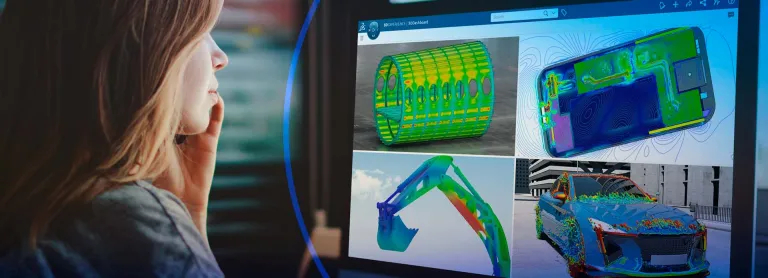

SIMULIA provides realistic simulation solutions that address various engineering challenges for industrial equipment manufacturers. We offer easy-to-use analysis tools that allow designers to make design decisions. SIMULIA also provides tools to automate the performance and optimization of design exploration studies. This broad simulation portfolio enables Industrial Equipment developers to leverage the right simulation tool for their specific application. Also, it allows collaboration between designers and analysis experts to accelerate fully informed performance-based design decisions and reduce the need for costly physical testing. Our design analysis solutions will allow you to accurately predict the complex real-world behavior of parts, large-scale structures, and complete systems.

Key Benefits of Industrial Equipment Solutions

Competitive Advantage

Faster bid response times through templated & democratized simulation, and knowledge reuse

Sustainable Designs

Reduced energy consumption, and improved overall system performance through predictive Virtual Twins, with optimized material consumption

Reduced Costs

Identify design flaws and optimize product designs using Simulation to reduce production costs, material usage, and waste.

No Late-Stage Failures

MODSIM enables a simulation empowered left-shifting strategy, to identify potential safety hazards and design failures of integrated equipment before they become critical

Automated Designer Friendly Workflows

Developing a good product is often about balancing requirements across multiple disciplines. To achieve that, we understand that engineers must sometimes conduct simulations in domains they are not necessarily experts in to balance multidisciplinary KPIs. The Dassault Systèmes solutions aim to make advanced analysis easy for anyone to use, with automated templates and guided processes to get the desired results without all the fuss.

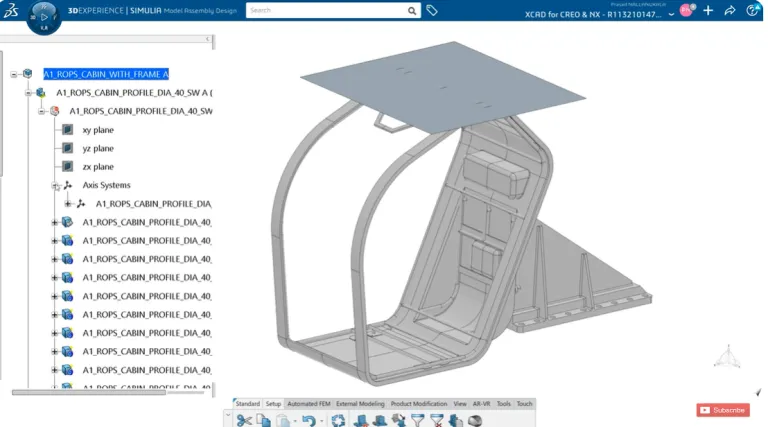

Multi-CAD Geometry Compatibility

The quality of input geometry defines your ability to run effective simulation analysis, and in the Industrial Equipment industry, we see all kinds of different input formats. Whether you are using the Dassault Systèmes SOLIDWORKS, CATIA, the 3DEXPERIENCE platform, or alternative third-party tools, our import processes retain the quality of your input data. SOLIDWORKS and CATIA input retain material information and parametrized dimensions, allowing you to run a Design Experiment or an optimization analysis without reworking your geometry.

Unified MODeling & SIMulation

Progressing towards a usable optimum through simulation means staying as close as possible to the geometry in your design tree and executing Simulation swiftly without being hindered by data conversion or data exchange issues. With our MOD-SIM approach, we combine the geometry information with the simulation model to seamlessly obtain new results as soon as the geometry changes without the need for new pre-processing.

Multi-Scale Simulation

There's a balance when dealing with solution accuracy and computational expense. Considering multi-scale problems can translate to leveraging system modelling of large complex systems where 3D information is not needed, and advanced 3D modelling where spatial details have a strong impact. The SIMULIA Industrial Equipment solutions combine these two worlds in sequential or co-simulations to allow you to see the impact of small geometry changes on high-level system KPIs.

SIMULIA Customers in Industrial Equipment

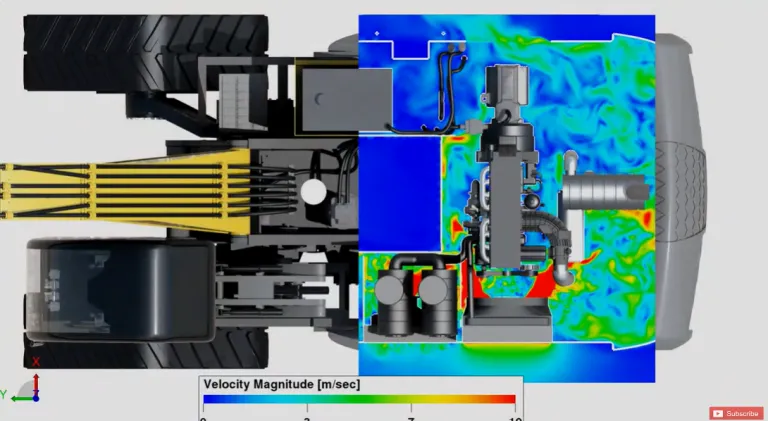

Heavy Mobile Machinery Design & Simulation

With ever-increasing regulations, heavy machinery equipment manufacturers are challenged to deliver machines that perform consistently in various operating environments. Farm equipment must be durable and able to perform a variety of tasks. Construction equipment must operate in highly regulated environments, in harmony with other surrounding machines and personnel. Mining equipment must haul a large quantity of material to ensure proper operating performance of the overall mining site.

Building Equipment Design & Simulation

The built environment and its equipment are becoming increasingly advanced and complex, requiring innovative solutions to address the challenges of design, manufacturing, and performance. This is in the context of increased scrutiny of the building sector, owing to a very high CO2 footprint, leading to novel design and construction approaches. Dassault Systèmes offers a range of solutions that focus on designing through simulation and creating a virtual twin of climate systems with people following equipment. These solutions cater to both the design of individual components and their installed behavior, taking into account environmental effects. By considering metrics across the entire lifecycle of an entity, from design to exploitation, these solutions aim to help companies create more efficient, sustainable, and innovative solutions for the built environment.

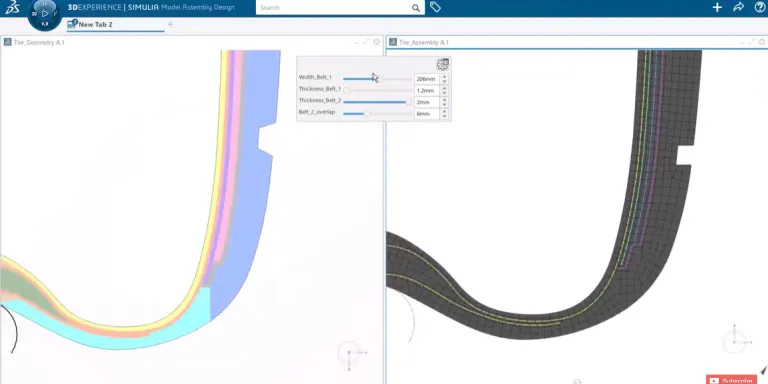

Tire Design & Simulation

As the world moves toward electric and autonomous vehicles, the tire demand is expected to surge by 2030. Tire manufacturers face the challenge of innovating faster while optimizing their supply chains for efficiency and cost-effectiveness. SIMULIA's Tire Design & Simulation solution leverages the 3DEXPERIENCE platform to enable manufacturers to advance the "Magic Triangle" of tire performance—Wet Grip for Safety, Wear Resistance for Lifetime, and Rolling Resistance for Fuel Efficiency—through early-stage, physics-based simulations. This unified design and simulation environment is leveraged throughout the whole lifecycle of the tire, from design and manufacturing to replacement management. SIMULIA solutions accelerate innovation and enhance tire performance across various conditions, ensuring a more efficient product development cycle.

Equipment Engineering

Whether at home or in a manufacturing plant, our workflows provide effective simulation solutions to improve the performance of your equipment. Target increased efficiency of your HVAC design to meet LEED certification, all while guaranteeing human thermal and acoustic comfort. Improve lubrication designs or machinery cooling noise, and give your assembly plant smart factory connectivity to always be a step ahead with Dassault Systèmes.

Wind Turbine Engineering

SIMULIA offers a comprehensive suite of products for engineering simulation and optimization, and enables collaborative solutions to help wind energy companies design wind turbine systems cost-effectively. Users can use Abaqus technology to design and analyze components and sub-assemblies ranging from composite wind turbine blades to drive trains, bearings, towers, and offshore foundations. SIMULIA technology enables collaboration across different groups and companies.

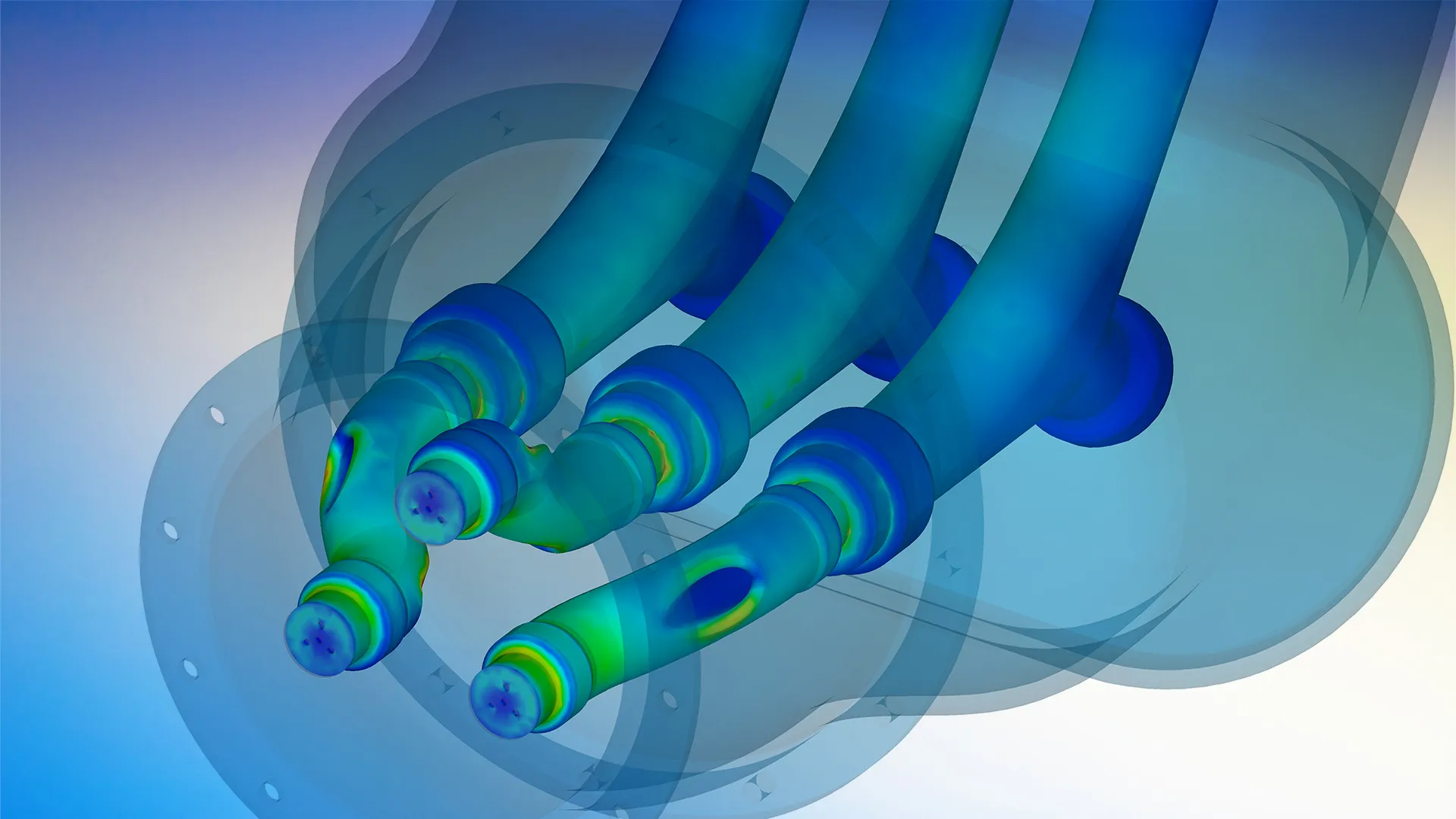

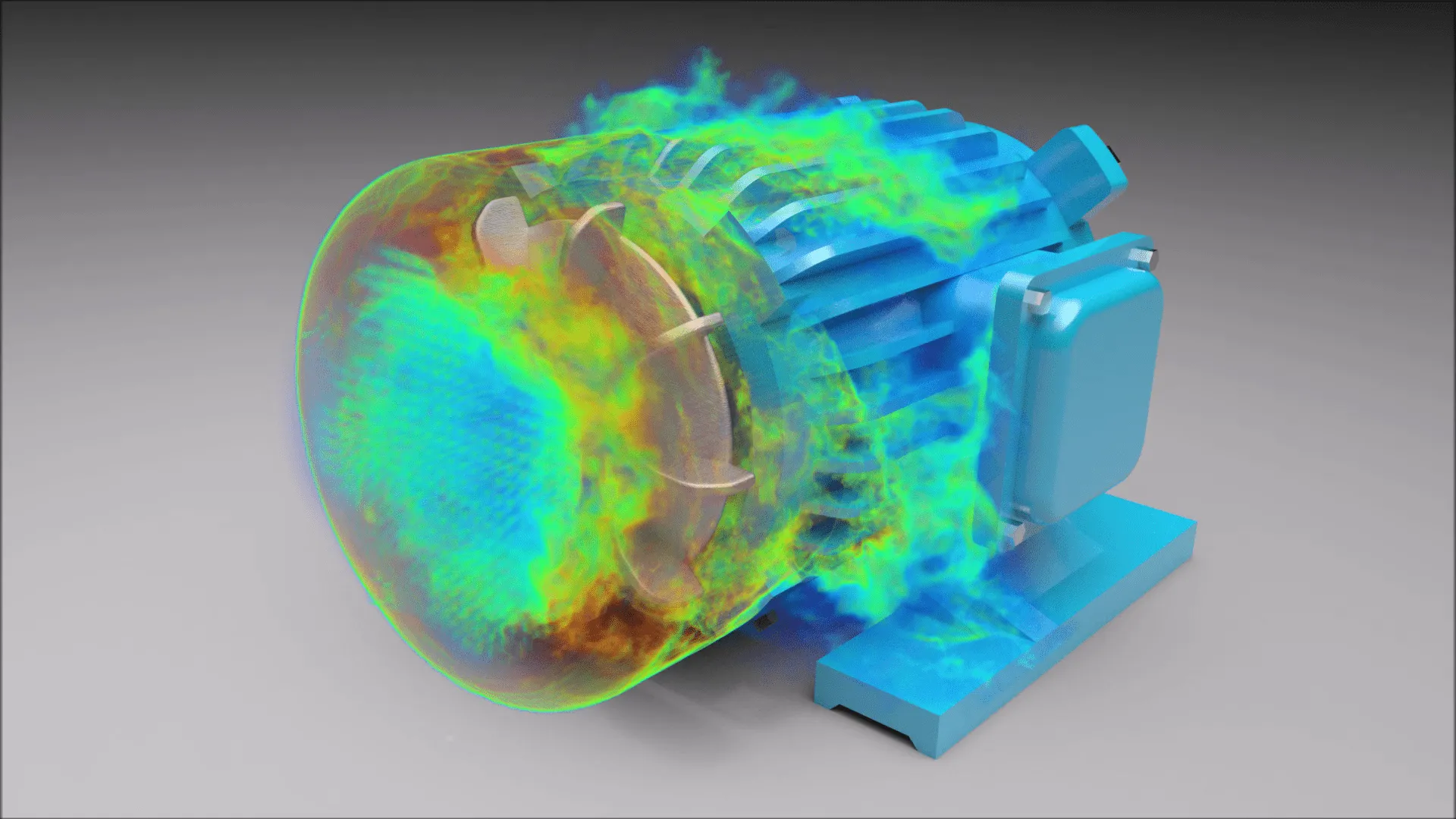

Power & Fluidic Equipment Design & Simulation

Energy efficiency and reduced maintenance costs are becoming the operating words for power and fluidic equipment manufacturers. Dassault Systèmes delivers best-in-class simulation solutions to help focus on these objectives during development. Explore the performance of power-generating systems such as turbines and electrical equipment, improve the lifetime of your pump and valve components, or reduce the noise from your cooling systems, all with our high-accuracy and connected workflows.

SIMULIA Industry Solutions for Industrial Equipment

The growing trends of the 4th Industrial Revolution - automation, IoT, artificial intelligence, big data analysis, networked communications, machine learning and cloud computing – mark a significant change in the way we work and how we engage with our customers. These emerging technologies are providing advanced and disruptive Industrial Equipment solutions that support the creation, production and delivery of sophisticated and efficient machinery, equipment and components.

Start Your Journey

The world of Industrial Equipment Engineering is changing. Discover how to stay a step ahead with SIMULIA.

FAQs About Industrial Equipment

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering