SIMULIA Aerospace & Defense Simulation Solutions

Experience sustainable, efficient aircraft design with Dassault Systèmes' SIMULIA and the 3DEXPERIENCE Platform. Unlock innovation in Aerospace & Defense.

Transforming Aerospace through Simulation Excellence

The Aerospace & Defense industry is facing increasing pressure to design more sustainable aircraft while also reducing production costs and increasing production rates. At the same time, program complexity is rising, and an evolving workforce requires new mechanisms for proper knowledge transfer. SIMULIA solutions, with their unique ability to provide accurate multi-scale and multi-physics simulations, are the key to overcoming the complex challenges faced by the Aerospace & Defense industry. By leveraging simulation early in the design process, these solutions can significantly reduce development time, the cost of physical testing, and the risk of program delays.

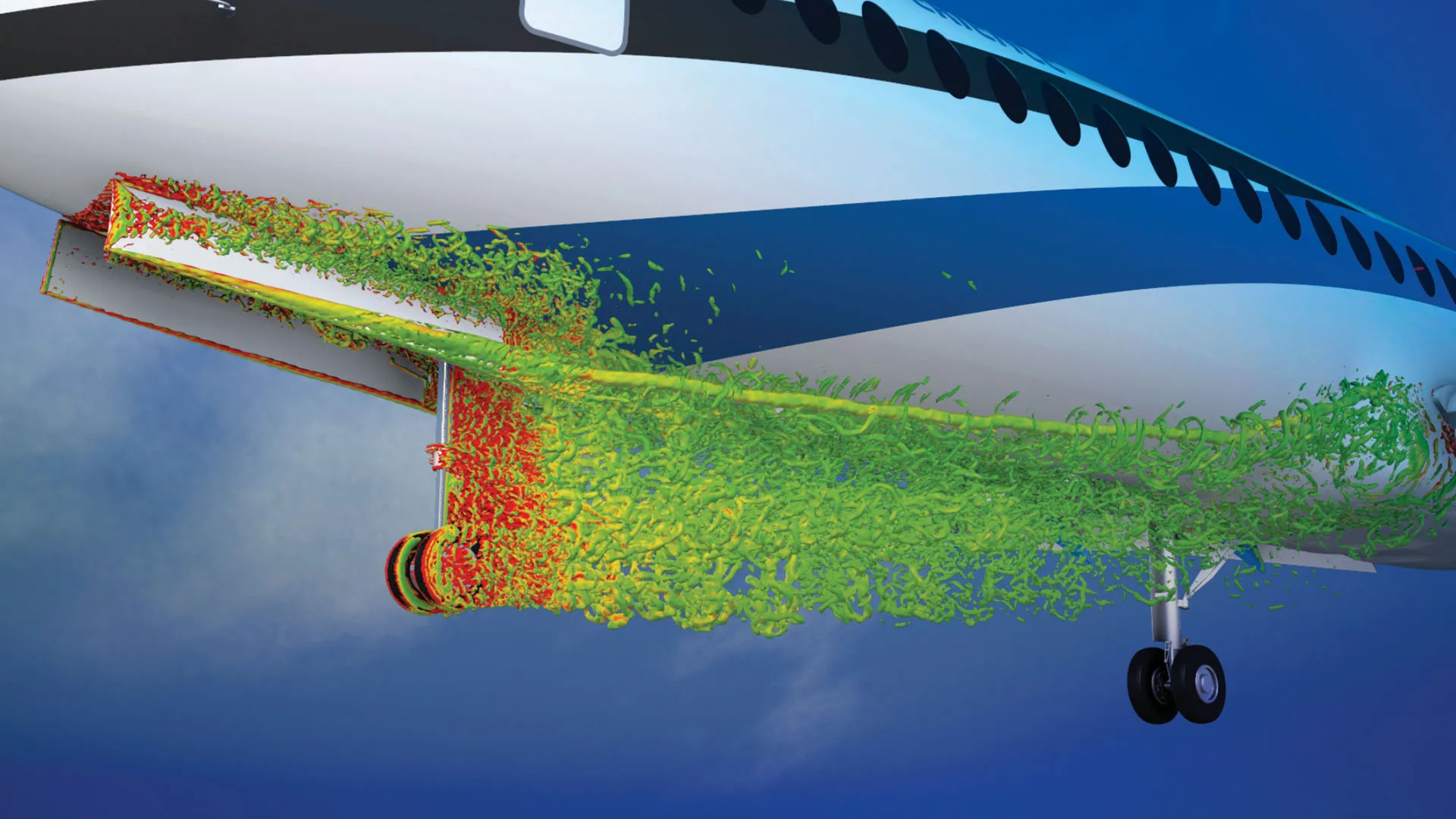

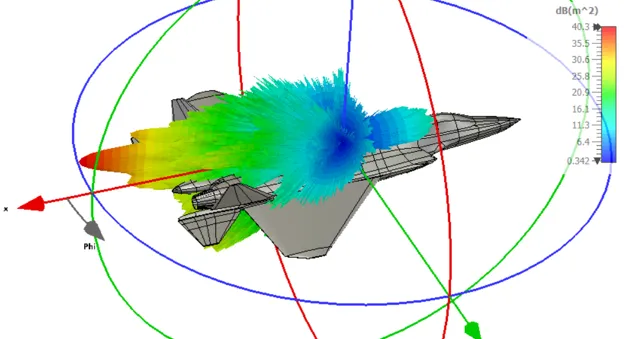

With SIMULIA solutions, structural analyses can be completed at multiple levels of model fidelity, ensuring seamless load transmission. Advanced aerodynamic capability allows the industry to expand CFD usage from the center of the flight envelope to explore the entire flight envelope, thereby reducing costly wind tunnel testing. Moreover, the noise levels of new aircraft designs can be reliably simulated, moving the industry toward digital noise certification. Lastly, our comprehensive electromagnetic solvers enable rapid antenna prototyping and ensure the reliability of all communication systems. Based on these capabilities, simulation usage can be expanded throughout the aircraft development process, from multi-disciplinary trade-off analyses to explore a broader design space in the concept phase, to supporting certification by analysis in the final stage of the development process.

Dassault Systèmes 3DEXPERIENCE platform provides crucial capabilities to leverage these simulation capabilities across large and small enterprises. By harmonizing all simulation data on a single platform, organizations can ensure end-to-end traceability across the development cycle, secure simulation data management, provide process governance to define, execute, and monitor simulations based on best practices, and enable seamless collaboration within and outside the organization. The result is faster product development that hits every safety, regulatory, sustainability, and customer target along the way.

Key Benefits of SIMULIA Aerospace and Defense Simulation Technology

Integrated Workflow

Enhance collaboration with seamless simulation tool integration on the 3DEXPERIENCE platform.

Compliance Assurance

Meet industry standards by supporting certification by analysis with validated simulations and unified process governance.

Early Risk Detection

Identify and mitigate design flaws early to avoid late-stage failures

Cost Savings

Reduce expenses by replacing physical tests with virtual simulations.

SIMULIA Customers in Aerospace & Defense

MODSIM for Aerospace & Defense

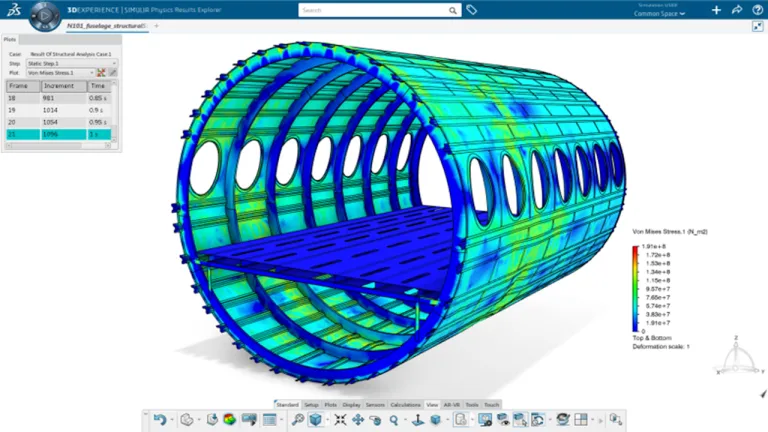

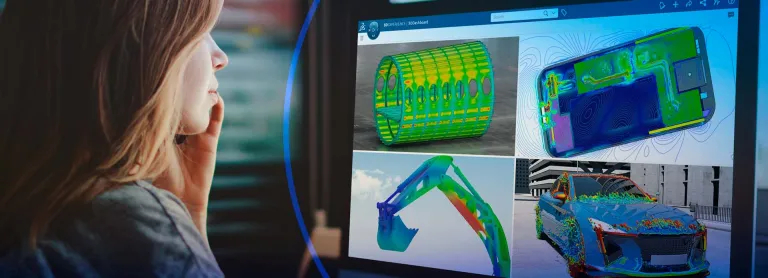

MODSIM unifies modeling and simulation on a common data model within a single user experience on the 3DEXPERIENCE platform.

MODSIM replaces traditional CAE processes, which typically rely on a sequence of disconnected operations to execute a simulation – extracting and simplifying CAD geometry, generating a simulation mesh, executing the simulation and postprocessing the results – with a continuous and fully integrated simulation process. Simulation data are directly connected to the geometry and model data, ensuring traceability, managing lifecycles and enabling automation and re-usability. This shortens the time to execute a simulation from weeks to days or even hours. And most importantly, frequent design iterations in the aircraft development process can be evaluated automatically since the simulation model is fully connected to the evolving design model.

In addition to this core MODSIM loop, the 3DEXPERIENCE platform enables the governance and traceability of all simulation data and processes, facilitates collaboration through change and issues management processes, and connects simulations to other critical elements of the development process, such as requirements, system models and physical tests.

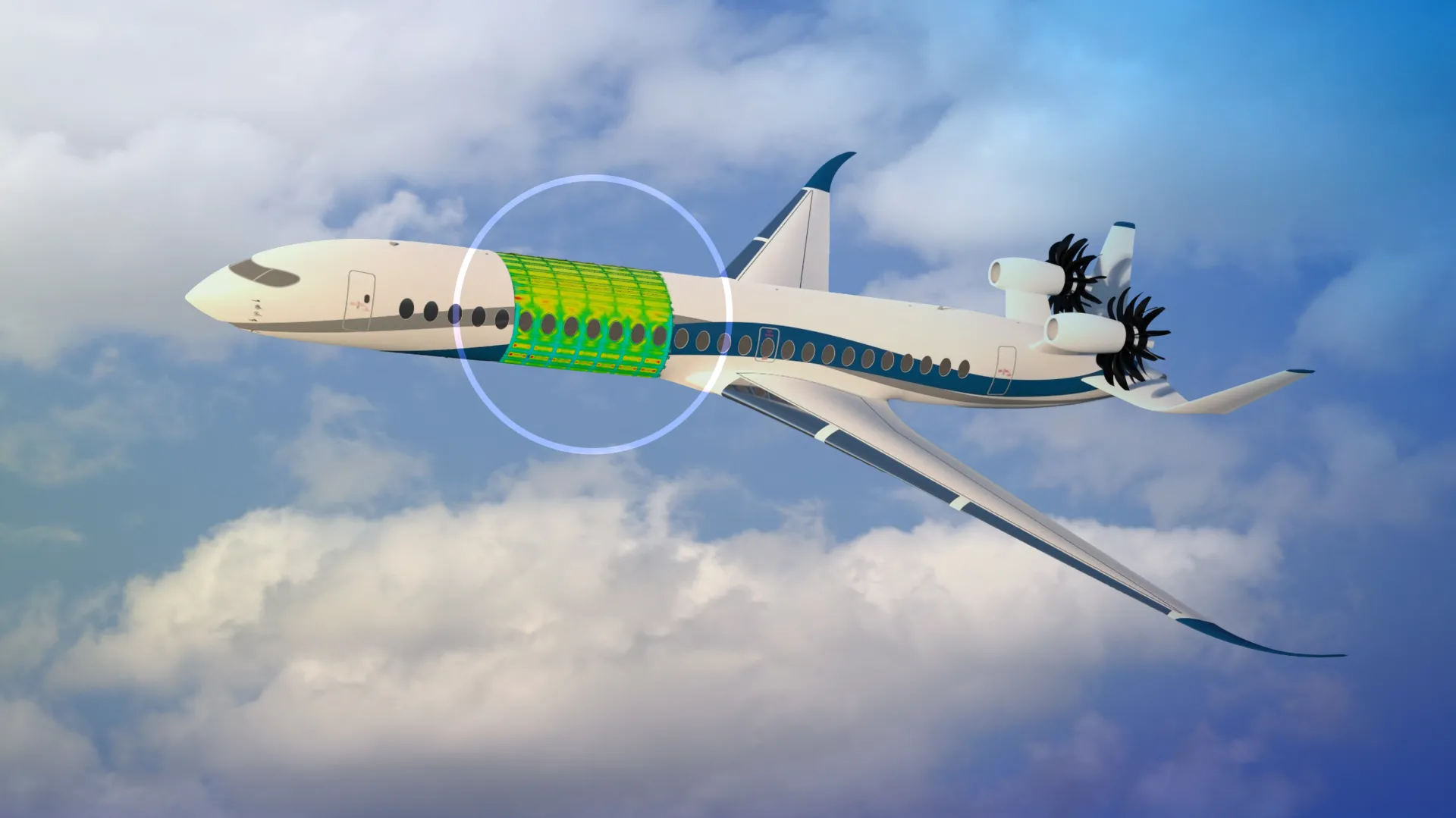

Aero-Structural Optimization in the Concept Phase

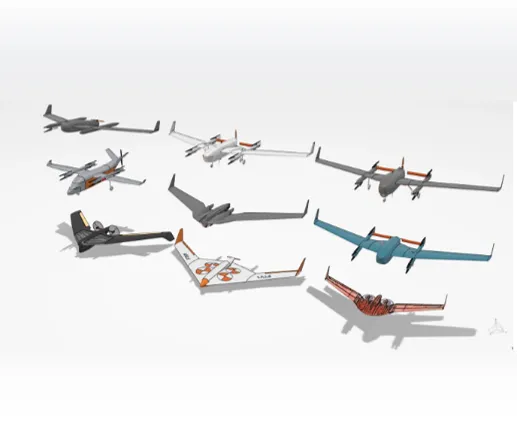

Aircraft Manufacturers have to increasingly explore novel aircraft concepts to respond to sustainability requirements and the emerging urban air mobility market. Traditional tools that heavily rely on internal knowledge from past programs will not suffice anymore.

SIMULIA enables the use of higher-fidelity simulation in the aircraft concept phase, leveraging a unique capability to quickly generate structural, aerodynamic and even electromagnetic models for thousands of potential shapes. This ensures an optimized concept from the very start of the program. These processes are seamlessly integrated with model-based systems engineering (MBSE) processes upstream and simulations in the preliminary and detailed design phase downstream in the development process.

Aircraft Certification by Analysis

Increased use of high-fidelity simulations to support the certification of new aircraft and variants is critical to avoid the costly delays and late-stage problems that have plagued almost every new aircraft program over the last decades.

SIMULIA offers advanced simulation capabilities with proven accuracy required to support certification, tools to maximize coordination and synergies between simulation, physical tests and flight tests, and process governance tools to provide the credibility assurance framework required by certification authorities – all seamlessly integrated on the 3DEXPERIENCE platform.

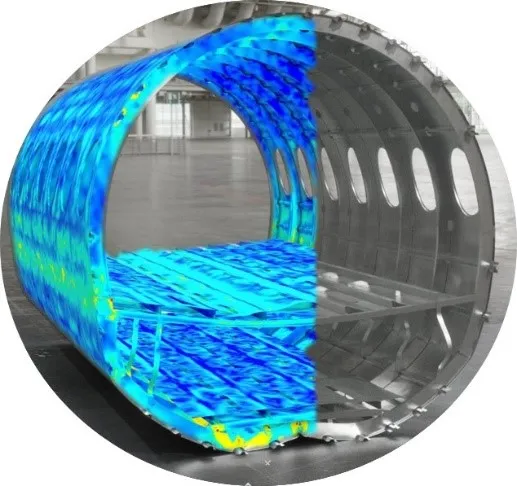

Structural Integrity

Aircraft structural certification and, ultimately, airworthiness require demonstrable compliance with federated requirements. Such requirements necessitate organizations and engineers to use physical and analytical tests, such as finite element model representations, to demonstrate an acceptably low loss of structural integrity within the aircraft's operating envelope and throughout its operational lifetime.

SIMULIA offers an accurate and scalable analysis portfolio capable of managing very complex assemblies, spanning multi-scales, diverse material behaviors, including advanced models for composites, providing informed perspectives for both design and producibility (manufacturing) contexts.

The Dassault Systèmes 3DEXPERIENCE platform elevates design integration and simulation governance under a MODSIM umbrella, leading to opportunities to realize significant improvements in data traceability and lifecycle, simulation reuse and engineering efficiency. Technology introductions to accommodate often disruptive, diverse design changes during early trade study or pre-feasibility explorations present a further emergent transformation opportunity.

Commercial Airplane Design

Transform the future of air travel with Dassault Systèmes SIMULIA’s commercial aircraft design solutions. Providing advanced solutions for structural analysis, aerodynamics and aeroacoustics, electromagnetics, vibroacoustics and motion analysis, our simulation tools enable aerospace manufacturers to optimize aerodynamic performance, structural integrity, fuel efficiency, and passenger comfort, leading to groundbreaking innovations in commercial aviation.

Accelerate your development processes with simulation processes on the 3DEXPERIENCE platform, based on a common geometry as your single source of truth, connected to program requirements, and fully automated updates as the design progresses.

Defense Aircraft Design

Stay ahead of evolving threats with Dassault Systèmes SIMULIA’s defense technology solutions. Our simulations enable defense professionals to develop and test modern defense airplanes, rotorcraft and ground systems, addressing complex requirements with advanced technologies to simulate unsteady aerodynamics over the entire flight envelope, complex nonlinear structural problems, and electromagnetic topics such as antenna design and interference, or radar cross section analysis. Connecting these technologies to empower our Dassault Systèmes industry-standard Model-Based Systems Engineering tools offers unparalleled advantages for proposal and concept stages.

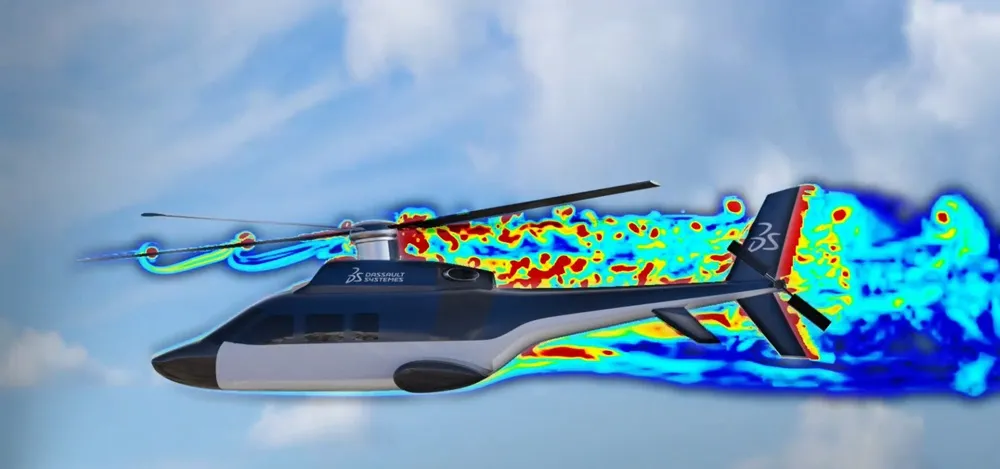

Rotorcraft Simulation

Rotorcraft and, more specifically, electric Vertical Takeoff and Landing (eVTOL) vehicles are transforming urban air mobility. Modern rotorcraft designs are driven by innovations that enhance performance, efficiency, and passenger comfort. As manufacturers compete to introduce revolutionary aircraft, leveraging cutting-edge simulations becomes crucial to validating pioneering concepts, ensuring structural integrity and developing aerodynamic solutions. Learn more about how 3DS's simulation portfolio and virtual twin technology can help design the rotorcraft of the future.

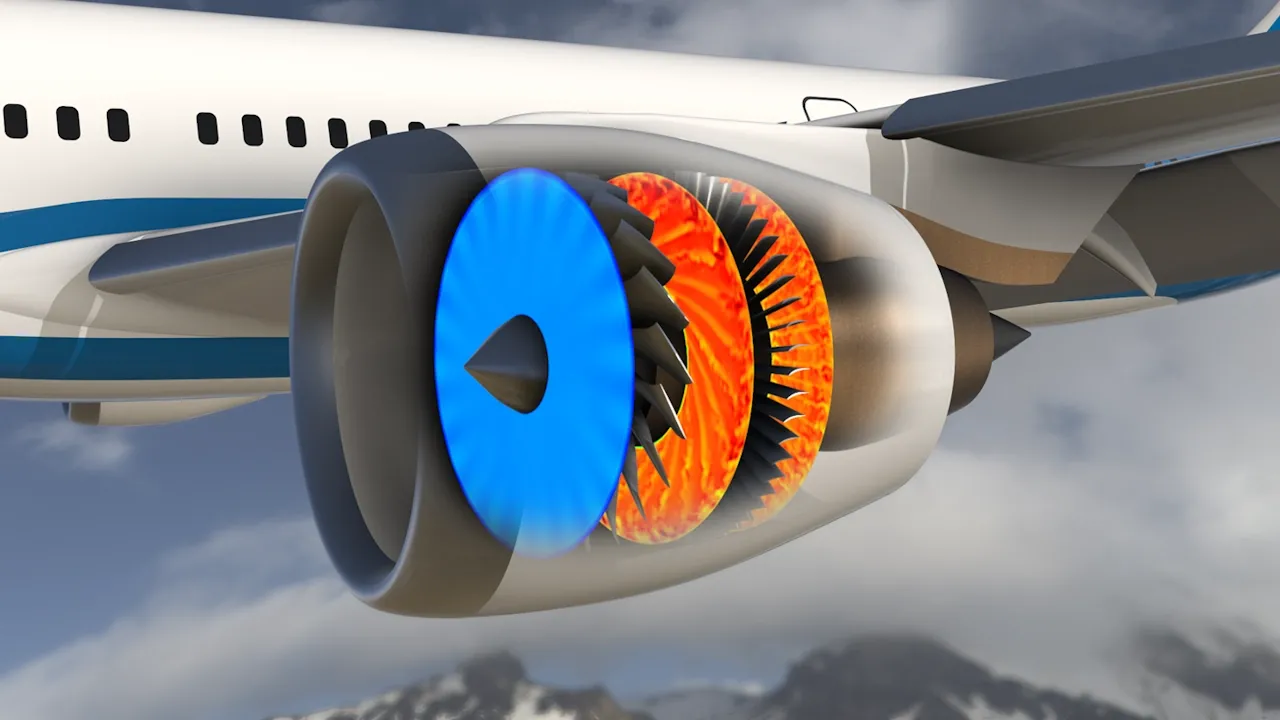

Aircraft Propulsion Systems Simulation

Propulsion systems have drastically increased in variety in the last decade to support new requirements, new architectures and enable new operations. Examples like open fan architecture, hybrid engines or traveling beyond Mach 1 are seriously pursued in industry. Bringing all these concepts and ideas to reality requires a large amount of engineering and simulation, to mature, validate and push towards certification. In this dedicated page, you can learn in more detail how SIMULIA and its technology portfolio can contribute to achieving these ambitious targets by providing domain-specific simulation capabilities. In addition to its simulation capabilities, the 3DEXPERIENCE platform also allows the necessary backbone for collaboration in a multidisciplinary environment.

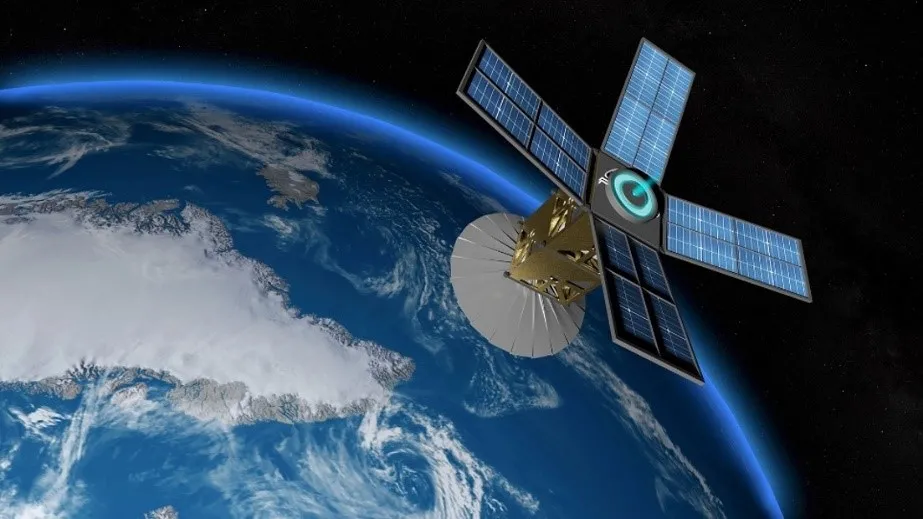

Spacecraft Simulation

Explore the cosmos with cutting-edge spacecraft design solutions from Dassault Systèmes SIMULIA. Our advanced simulation technologies empower aerospace engineers to optimize every aspect of launch vehicle and spacecraft performance, ensuring reliability and efficiency in the harshest environments of space.

SIMULIA provides a comprehensive set of simulation capabilities to address typical advanced requirements for satellites and launch vehicles, from lightweighting and additive manufacturing, communication technologies, and shock and vibration handling during launch and deployment.

SIMULIA Industry Solutions for Aerospace & Defense

As systems become more complex to design, build and deliver, original equipment manufacturers (OEMs) and suppliers need to accelerate innovation, drive efficiencies and move to the factory of the future to allow for greater production agility. This requires a new way to conceptualize, design, manufacture, test, certify and sustain new air and space vehicles.

Start Your Journey

FAQs about Aerospace & Defense Simulation Solutions

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering