SIMULIA Marine & Offshore Solutions

Simulation is helping marine engineers to develop reliable, high-performance and sustainable vessels, ports and offshore infrastructure.

Simulation for the Marine & Offshore Industry

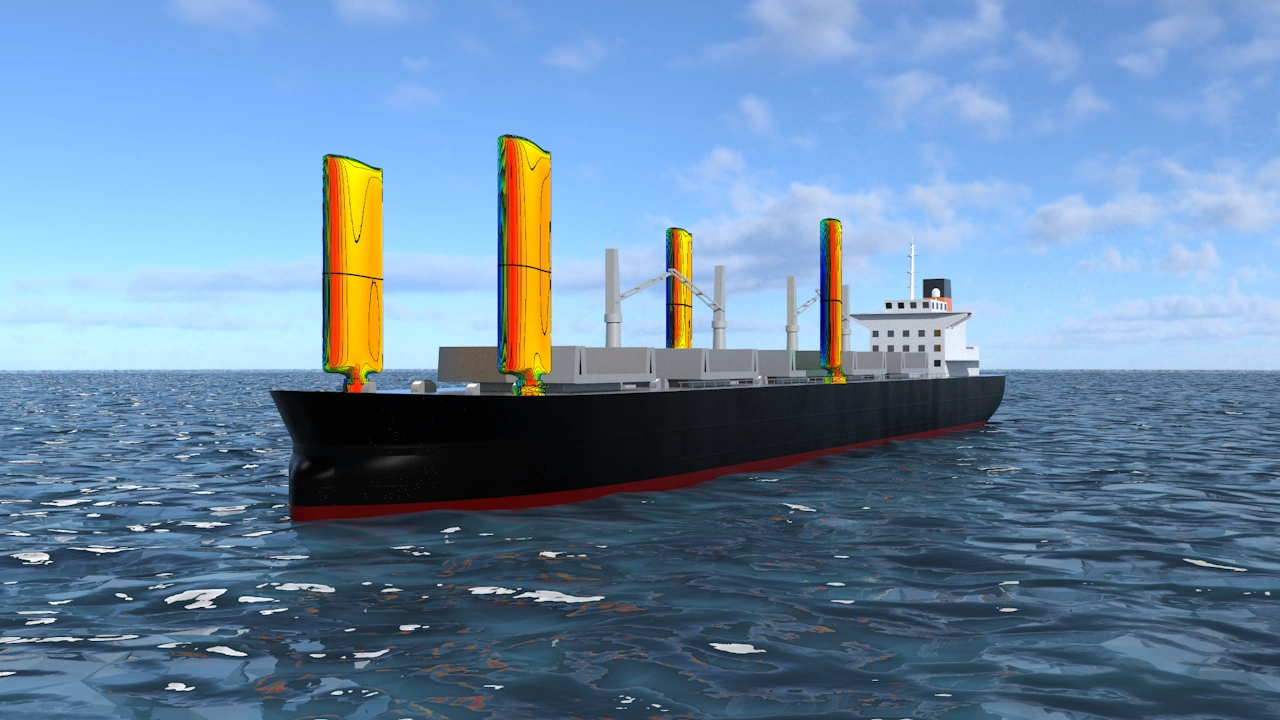

Ocean-going ships and offshore platforms are some of the largest structures built by humans and have to be able to withstand the full force of storms, winds and waves. Ship architects and marine engineers must ensure that civilian and military vessels can operate safely and reliably for many years. Increased focus on the environmental costs of shipping also means that shipwrights must develop less polluting and more efficient ships, including innovative technologies such as hybrid electric power and new forms of wind-assisted propulsion.

Simulation is helping the marine and offshore industry meet the demands of the modern world. Engineers can analyze how a vessel will perform in various scenarios without needing to construct a prototype or commit to sea trials. Problems can be identified during the design phase and resolved quickly, saving costs and time compared to fixing issues after construction.

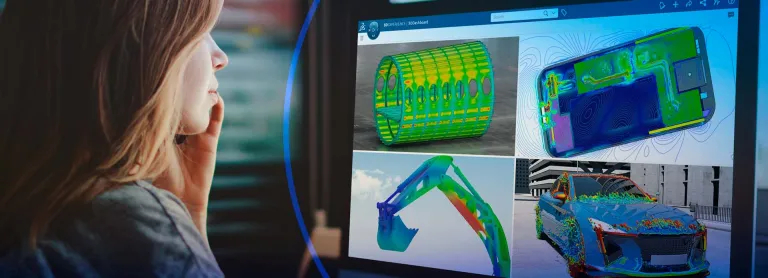

The SIMULIA brand of Dassault Systèmes offers a portfolio of simulation tools covering multiple physical disciplines. Simulation can be integrated into industry-standard computer-aided design (CAD) workflows with unified modeling and simulation (MODSIM).

Key Benefits of SIMULIA Marine & Offshore Solutions

Accelerate development

Reduce physical testing, iterate faster and cut deployment time.

Improve performance and safety

Evaluate real-world performance even in the most extreme sea conditions.

Optimize designs

Identify the most efficient and cost-effective designs, satisfying all design requirements.

Reduce costs

Reduce expensive prototypes, optimize production processes, and minimize the risk of late-stage problems and expensive retrofits.

MODSIM for Marine and Offshore

Integrated modeling and simulation (MODSIM) allows analysis and optimization during the entire design cycle, from the concept phase to the final testing. With MODSIM, engineers can "left-shift" analysis, allowing them to assess device performance virtually and identify problems early, before re-design costs spiral. Virtual testing can complement or replace physical measurements and trials, reducing the costs of manufacturing and testing prototypes. People across teams can collaborate in a common environment on the 3DEXPERIENCE platform with a single source of truth to produce an optimal design, and a digital thread provides traceability through the entire design process.

Multiphysics Simulation for Marine Applications

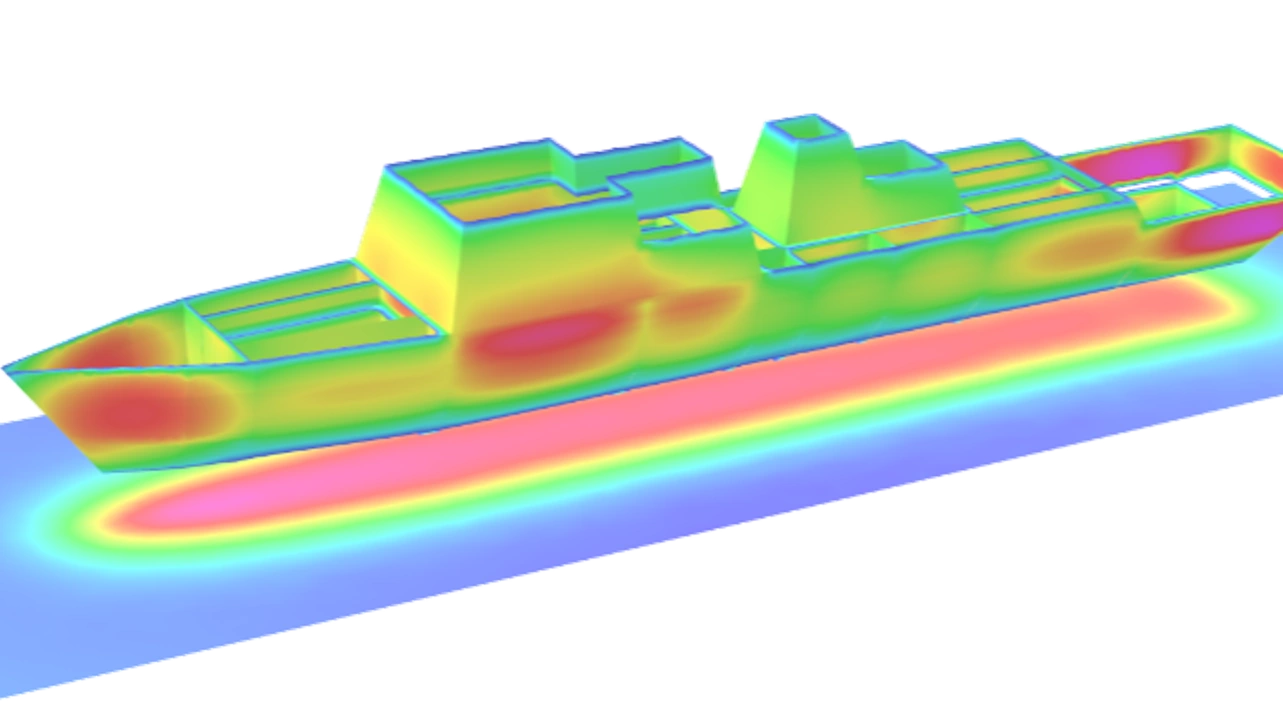

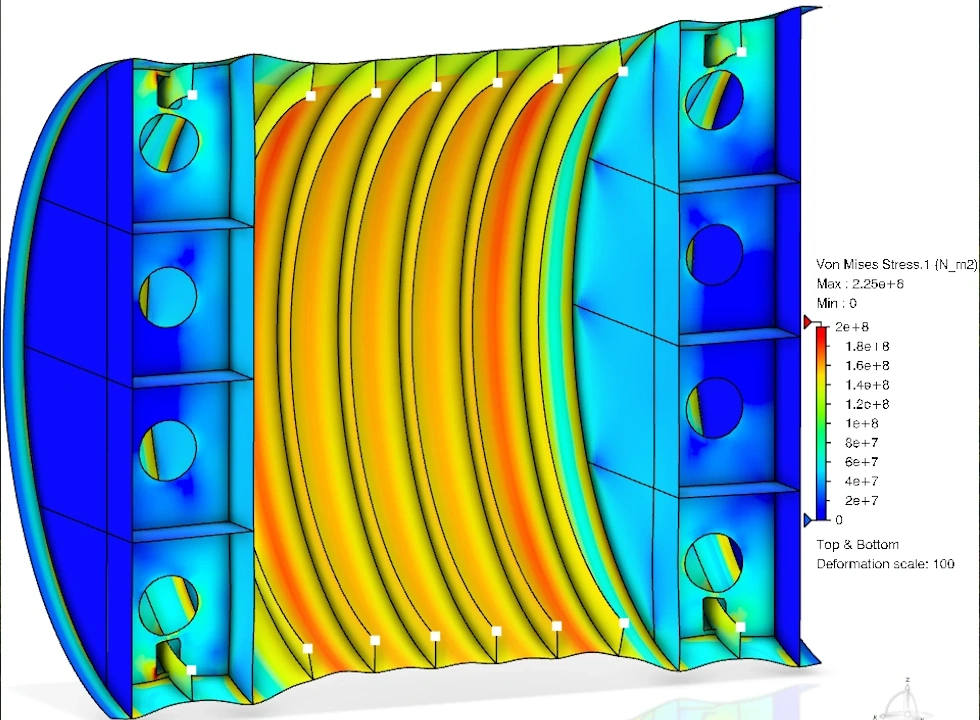

Designing a successful ship that can reliably withstand challenging sea conditions is a multiphysical problem. Structural simulation reveals how a vessel withstands forces such as waves or pressure underwater, electromagnetic simulation helps systems integrators to optimize the performance of radar and communication antennas, computational fluid dynamics (CFD) can be used to model heat flow and ventilation, and multibody dynamics simulation can be used to design engines, turbines and propulsion systems. All of these physical disciplines are available in the SIMULIA portfolio.

SIMULIA Customers in Marine & Offshore Solutions

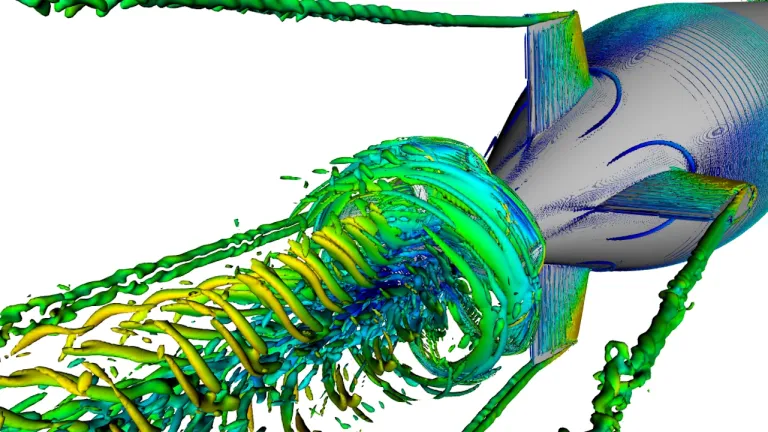

Ship Propulsion Simulation

A ship’s propulsion system needs to move tens or hundreds of thousands of tons through the water, reliably and efficiently. Increased awareness of sustainability means there is growing demand for propulsion systems that use less fuel and produce less pollution, and renewed interest in alternative technology such as nuclear, hybrid or battery electric, and even wind power.

Simulation can be used to design all parts of the propulsion systems, from the engine to the powertrain to the propeller. Component durability can be optimized – for example, improving lubrication to increase the life of a gear under wear, or analyzing cavitation around propeller blades. Environmental effects such as noise, vibration and exhaust management can also be considered by simulation, improving passenger experience and helping to meet port regulations.

Ship System Simulation

The modern ship is equipped with numerous subsystems to ensure safety, support operations and improve onboard comfort. Simulation can be used both to design components in isolation and to optimize their performance when installed on the ship.

Radar, communication, navigation and electromagnetic countermeasure systems all rely on antennas and microwave/radio frequency components. Simulation can be used to analyze the installed performance of antennas when placed on a large, metal ship, and to mitigate interference and environmental electromagnetic effects (E3).

Heating, ventilation and air conditioning (HVAC) can be analyzed to ensure that safe, comfortable conditions are maintaining throughout the ship and that sufficient cooling is supplied to the engines. Ducts and pipes can be analyzed to ensure their structural integrity.

Shipyard Simulation

A single ship represents an investment of many millions of dollars – the largest aircraft carriers cost billions in construction alone. Simulation can cut development times and costs, and help to find innovative construction solutions that save time and money while meeting demanding performance targets.

For commercial vessels, ship architects and engineers use SIMULIA simulation tools as part of a modeling and simulation (MODSIM) workflow. The structural integrity of a vessel’s hull and superstructure can be analyzed during the earliest stages of design, giving engineers insight into how it will withstand real sea conditions.

Naval vessels – including submarines and other underwater vessels – face particular challenges, having to survive and maintain high performance under all conditions, and threat scenarios. Simulation can allow engineers to test whether their designs meet exacting military standards and the demands of modern theaters.

In the luxury end of the market, yachts and other specialty vessels are bespoke, one-of-a-kind ships designed in active collaboration with the customer and their demands. MODSIM enables architects to demonstrate the performance of the vessel to the customer during the concept stage and quickly make changes in accordance with customer wishes.

Sea Port Simulation

The world’s trade could not function without ports. These facilities need to transfer many thousands of tons of cargo per ship safely, efficiently and reliably. Simulation helps port facilities engineers and managers to design equipment and operations to optimize performance.

Pollution from ports can cause political and social opposition as well as potentially leading to fines and expensive remedial work. Simulation can model the dispersion of industrial pollutants and possible gas leaks according to prevailing winds and control their impact on the port workforce and the neighborhood. It can also assess the port areas most exposed to noise and the impact on the local community.

Rising sea levels and changes to rain patterns threaten ports. Simulation helps to mitigate the risk of flooding and anticipate rising waters during the extension or rehabilitation of port area. Siltation and the impact of dredging can also be modeled in estuaries or harbor entrances based on tidal, flows and other events for dredging execution planning and a better port resilience.

Structural simulation reveals how port infrastructure such as piers, cranes and bridges withstand challenging collisions such as storms and collisions. Simulation is also helping to enable smart ports, with electromagnetic simulation helping wireless network integrators to maximize signal coverage in ports and identify zones with poor reception.

Offshore Structure Simulation

The ocean offers a bounty of resources, and much of our energy now comes from structures built at sea – from oil and gas platforms to offshore wind farms. The transportation and strategic opportunities of the sea are also made possible by offshore constructions. For safety and environmental reasons, these structures need to be able to withstand even the worst-case scenario for storms, waves and impact.

With simulation, engineers can analyze the structural performance of their designs under a wide range of different real-world conditions. Potential issues can be identified and resolved at the design stage, reducing the cost of rework and the risk of failure later.

The costs of construction in the open ocean makes installation and repair work prohibitive – structures have to be right first time. Large investments can be lost due to delays or cancelled projects where construction cannot proceed. Simulation helps to plan installation and analyze the feasibility of a project under difficult environmental conditions, reducing the risk of construction work failing.

SIMULIA Industry Solutions for Marine & Offshore

Increasing competition and environmental objectives are pushing shipbuilders to reinvent themselves in order to produce faster, smarter and more sustainably.

Powered by the 3DEXPERIENCE® platform, the virtual twin technology enables shipbuilders to implement a robust digital continuity strategy in a single, unified environment — unlocking new efficiencies and transformative results.

Start Your Journey

The world of Marine & Offshore is changing. Discover how to stay a step ahead with SIMULIA.

FAQs about Marine & Offshore Solutions

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering