Simulate particulate instantiation, transport, deposition, and filter clogging to predict how air purifiers reduce localized contamination and stale air. Optimize filter placement and flow rates to improve indoor air quality, extend maintenance intervals, and minimize contamination clearing time.

Equipment Engineering

Minimize downtime costs with durable products and robust manufacturing equipment designed and optimized by SIMULIA industry solutions.

Equipment Operating Performance

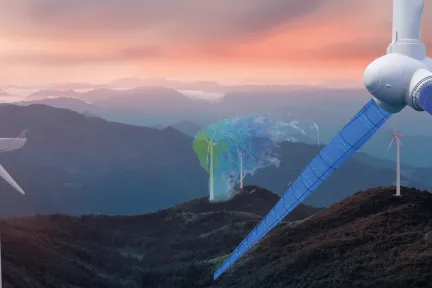

Advancing HVAC technology is central to cutting energy waste, improving system reliability, and maintaining safe, comfortable indoor environments. Modern HVAC systems are expected to meet multiple, often competing, demands. They must safeguard air quality in the face of challenges such as pandemics and aerosol contamination, while delivering high levels of air cleanliness. At the same time, they are required to operate efficiently without compromising thermal comfort, and to do so quietly, minimizing noise that can affect occupant well-being and productivity.

SIMULIA enables smarter HVAC design through advanced simulation solutions. Powered by the 3DEXPERIENCE platform and its BIM capabilities, HVAC systems can be engineered and optimized for maximum aerosol filtration, uniform and reliable thermal comfort, and minimal operational noise.

Key Benefits of SIMULIA Equipment Engineering Solutions

Integrated Multidiscipline Design

Unify energy, structural, acoustic, and thermal simulations in a single development process.

Increased Reliability

Predict performance over time to reduce downtime, costs, and maintenance frequency.

Lower Noise Emissions

Use high-fidelity simulation to minimize noise while optimizing airflow performance.

Optimized Component Performance

Virtually test and refine designs to reveal insights beyond physical testing.

Equipment Engineering Workflows

HVAC Components

Electrical Equipment

Machinery and Fabrication

Powertrain and Rotating Machinery

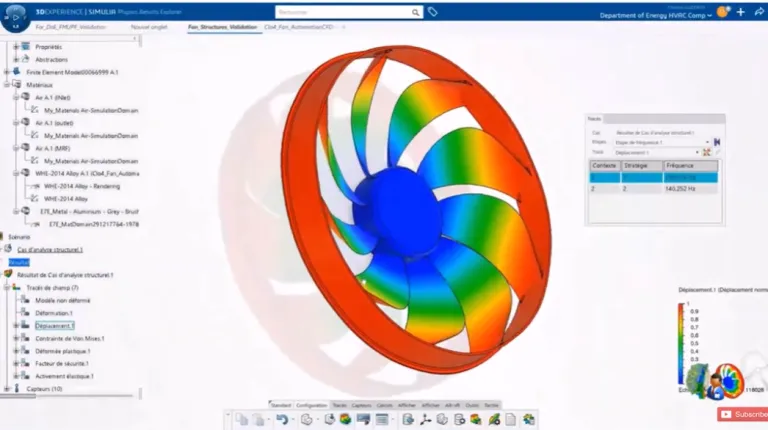

HVAC Components Workflows

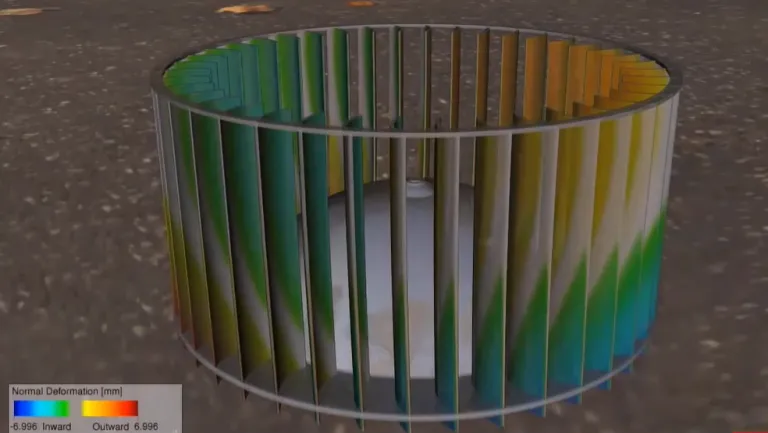

Reducing Noise

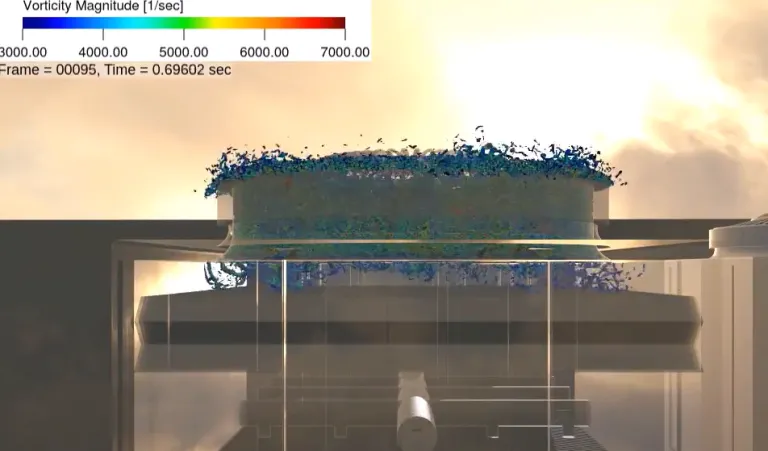

High-fidelity computational fluid dynamics simulations enable direct, accurate noise prediction, while advanced aeroacoustic post-processing identifies dominant noise sources at both component and system levels. This simulation-driven approach helps meet acoustic regulations early in the design phase.

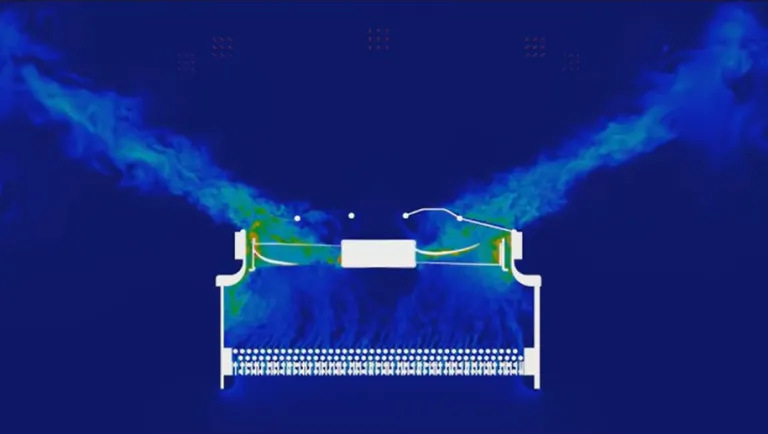

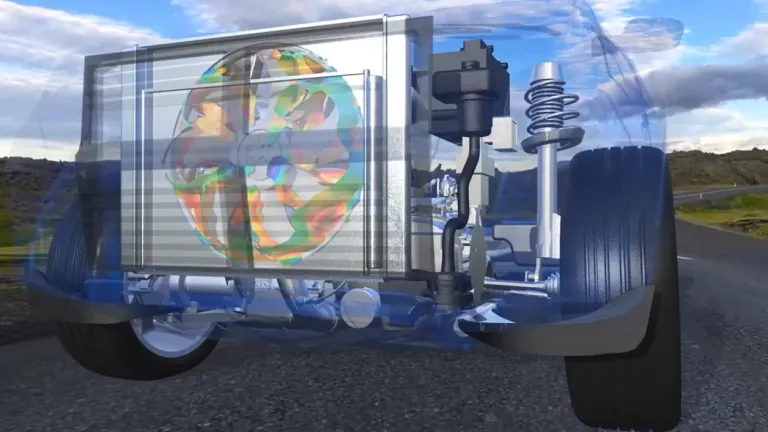

Air Filter Performance

Simulation with computational fluid dynamics help analyze the impact of filter clogging on aerodynamic and thermal performance of the HVAC as a function of time. The transport of contaminants and impure air removal process in vehicle HVAC system can be evaluated digitally. Different filter designs, human occupancy or environmental conditions can be virtually tested to replicate real world scenarios to improve building air quality.

Air Filter Efficiency

Assess HVAC and filter effectiveness for indoor air quality, predicting filtration efficiency by particle size and percentage while evaluating impacts on thermal comfort, acoustics, energy efficiency, and MERV ratings over time.

Air Filter in Building Spaces

Optimize System

High-fidelity CFD simulations enable direct and accurate noise prediction, while advanced aeroacoustic post-processing identifies dominant noise sources at both fan and system levels. This simulation-driven approach helps meet acoustic regulations early in the design phase.

1D/3D Coupled Simulations

Couple CFD with system modeling to optimize HVAC components across varying operating and weather conditions, integrating experimental and 3D simulation data as 1D behavior laws via Functional Mockup (FMU) interfaces to balance accuracy, complexity, and development time.

Heat Exchangers

Couple fluid flow and heat transfer in a single simulation. Improve the integration of heat exchanger in your system by ensuring maximum heat exchange. Include coolant computation, flow aerodynamics and convection, and thermal conduction and radiation in the simulation.

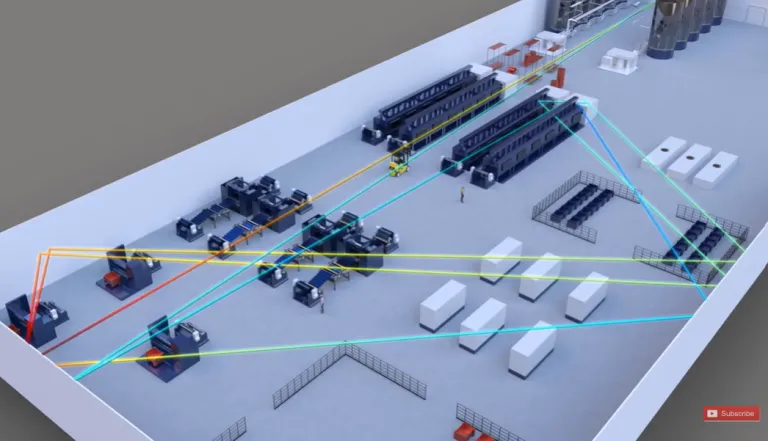

Electrical Equipment Workflows

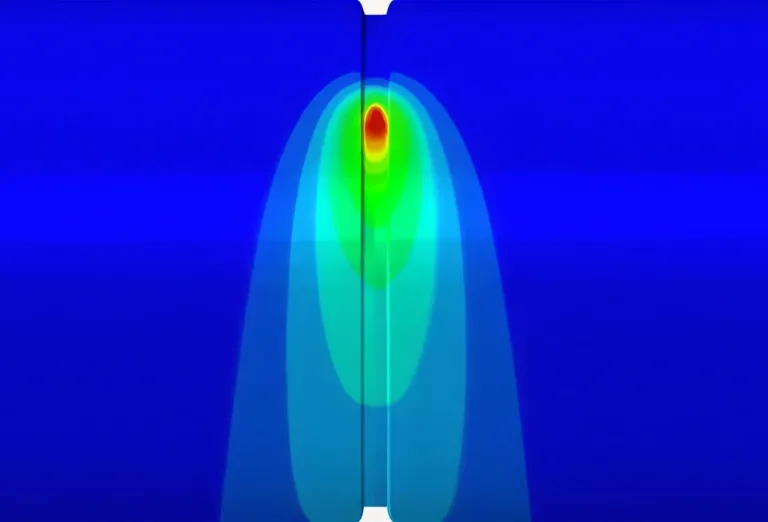

Antenna placement

Antenna performance depends heavily on its operating environment. Assess material impacts on coverage and link quality, identify co-site interference, and optimize antenna arrays using the 3DEXPERIENCE dedicated app to evaluate positioning, directivity, and blind spots for reliable IIoT connectivity.

Thermal performance

Predict thermal loads by coupling electromagnetic and thermal solvers. Safely investigate novel designs numerically eliminating unnecessary and destructive tests and also reducing the number of prototypes. Emulate costly mandatory tests and determine pass-fail compliance to avoid late stage failures. Integrate simulation in early design stages to reduce product development costs.

Machinery and Fabrication Workflows

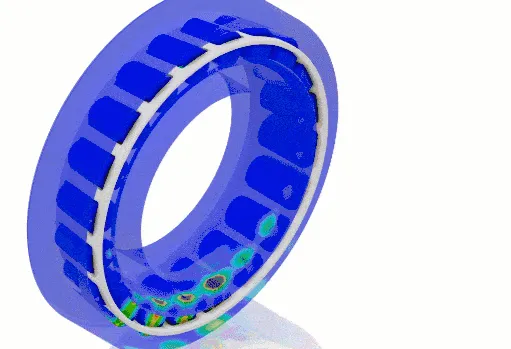

Powertrains and Rotating Machinery Workflows

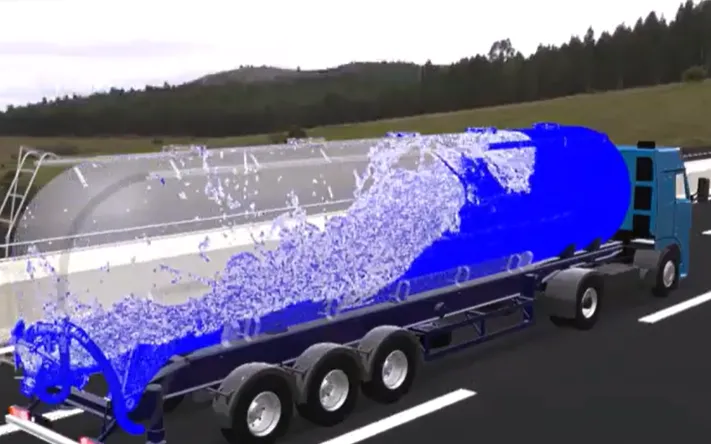

Tank Sloshing

For less challenging workflows like Tank Sloshing, the ability to easily sweep multiple operating conditions in a simple and agile way thanks to a best-in-class user experience and ultra-fast performance on very modest computing resources.

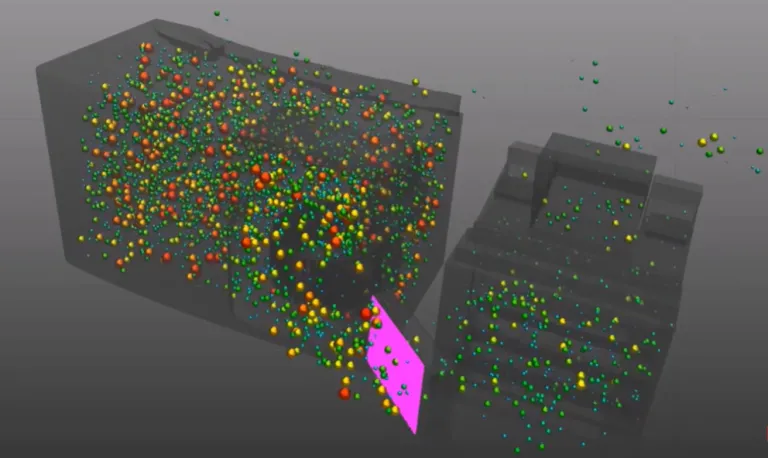

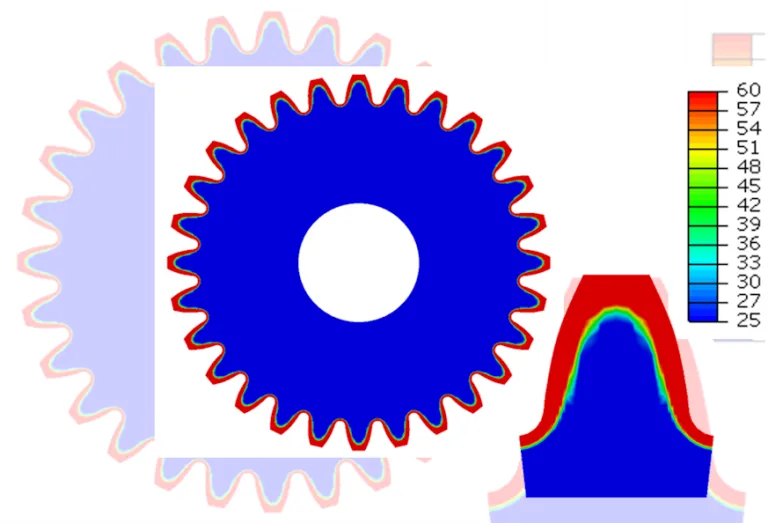

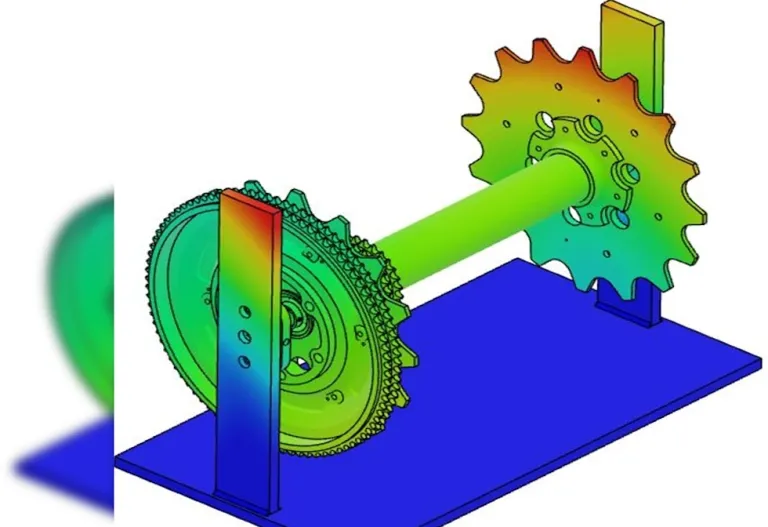

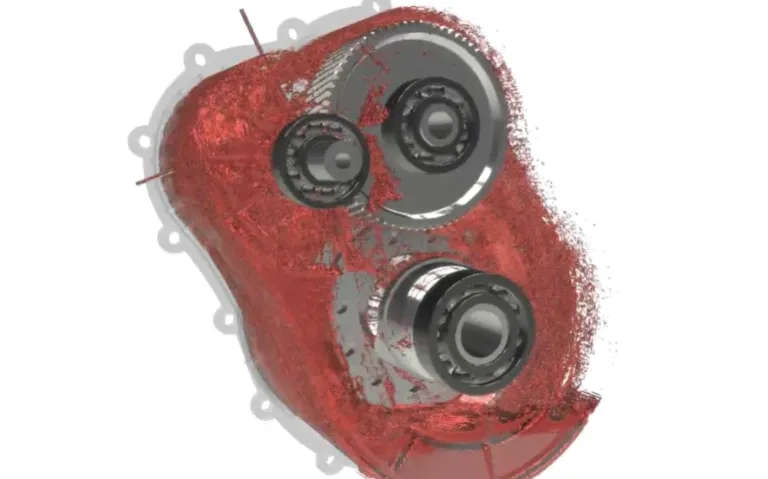

Gearbox Lubrication

Our GPU native solution empowers designers and analysts to perform complex Powertrain simulations, that involves multiphase flows and moving parts, such as Gearboxes, in a very fast and affordable way, without the significant hardware and long turnaround time that traditional CPU solutions required.

Start Your Journey

The world of Industrial Equipment Engineering is changing. Discover how to stay a step ahead with SIMULIA.

Industry Processes for Equipment Engineering

FAQs about Equipment Engineering

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering