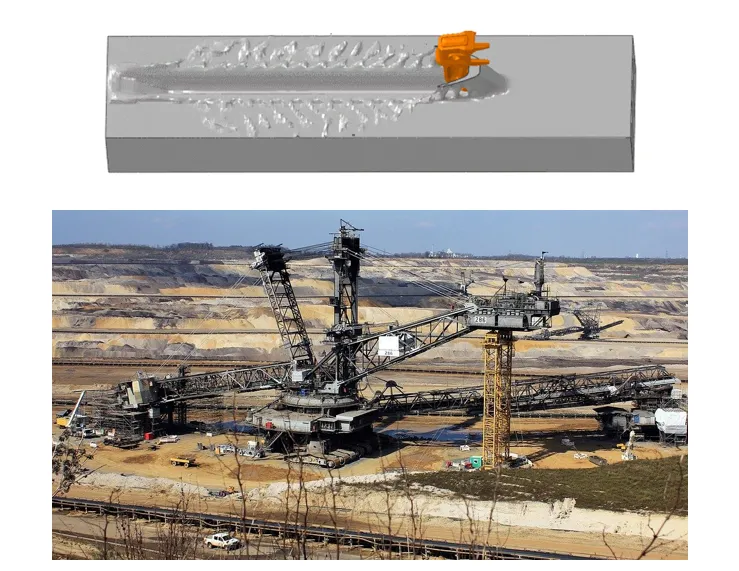

Heavy Mobile Machinery Design & Simulation

Optimize performance, reduce costs, enhance safety, and ensure reliability using SIMULIA Heavy Mobile Machinery Design & Simulation solutions.

The Challenge: Designing Reliable Heavy Mobile Machinery

Heavy mobile machinery, including farm, construction, and mining equipment, must perform reliably in harsh and diverse environments. Manufacturers face the challenge of ensuring durability, efficiency, and safety under heavy loads, fatigue, thermal stress, and vibration. Machines must meet strict regulations, support varied operational tasks, minimize downtime, and reduce maintenance costs, all while maintaining operator comfort and productivity.

How SIMULIA Delivers Results

SIMULIA enables engineers to optimize heavy mobile machinery across key domains:

- Build Stronger Machines: Analyze components and assemblies under complex loads for reliable performance.

- Increase Longevity: Evaluate fatigue and failure modes to extend equipment life and reduce maintenance.

- Enhance Operator Comfort: Predict and mitigate noise and vibration for safer, quieter operation.

- Maintain Optimal Performance: Simulate thermal and fluid behavior to prevent overheating and ensure efficiency.

Key Benefits of SIMULIA Heavy Mobile Machinery Solutions

Reduce work through automation

Accelerated design and simulation integration reduces work and enables extensive virtual testing

Reduce physical testing

Enhances certification confidence by minimizing physical testing through digital certifications of DEF tank & ROPS

Replicate real world operating conditions

Simulates real-world conditions for diverse drive cycles and environmental extremes

Enable multi-physics evaluation

Facilitates comprehensive multi-physics evaluations to improve noise reduction, structural integrity, and energy efficiency

SIMULIA Customers in Heavy Mobile Machinery

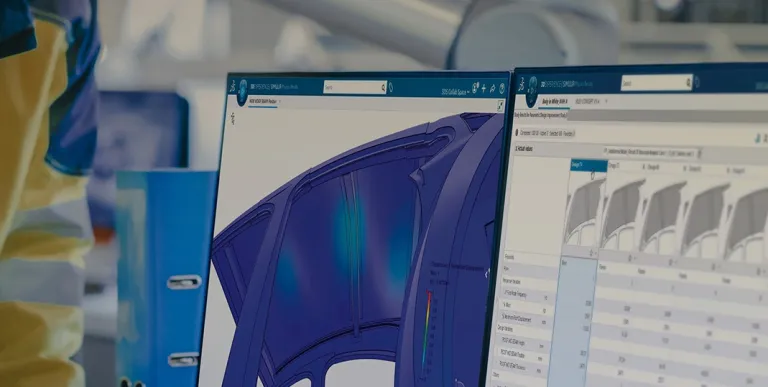

Accelerate Projects and Reduce Costs with MODSIM

MODSIM helps eliminate inefficiencies and incomplete designs, cutting project costs while improving planning accuracy.

By integrating CAD and CAE tools, MODSIM streamlines workflows, accelerates project timelines, and prevents costly delays.

Learn how MODSIM enhances collaboration, drives innovation, and boosts profitability, helping businesses maintain a competitive edge in industrial equipment.

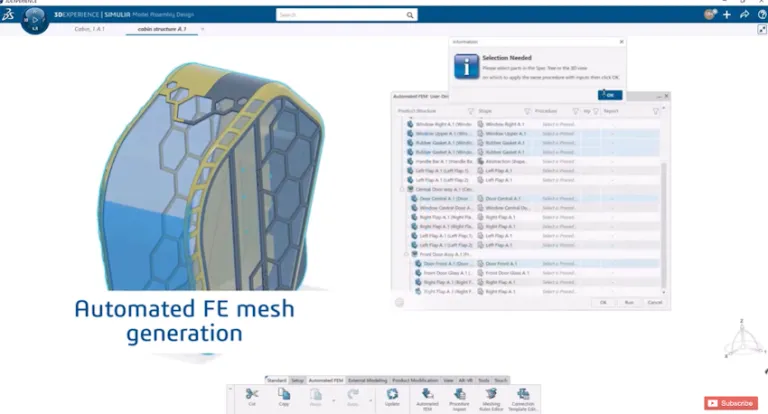

MODSIM for Industrial Equipment Design

- Integrated Modeling & Simulation: Unify CAD and CAE tools to streamline collaboration and reduce design costs.

- Early Issue Resolution: Address technical challenges early in the process to minimize costly changes.

- Key Features:

- Automated modeling and analysis templating for faster design evaluations.

- Virtual twin simulations for confident decision-making.

- User-Friendly Platform: Designed for quick adoption, enabling teams to work efficiently in a collaborative environment.

Ensure Equipment Reliability with High-Fidelity Multiphysics Simulations

Discover how SIMULIA’s Equipment Strength and Durability Performance solution enables end-to-end tracking of project requirements from ideation to product rollout. By providing a single source of truth representation of design and simulations, it reduces costly miscommunications between teams and avoids ensuing delays.

Heavy Mobile Machinery Design & Simulation Workflow

Heavy Machinery Structural Engineering

Heavy mobile equipment must operate under strenuous conditions for decades, necessitating durable designs to reduce service downtimes and potential downstream effects. The demand for customized variants further complicates manufacturers' ability to maintain a durable product portfolio.

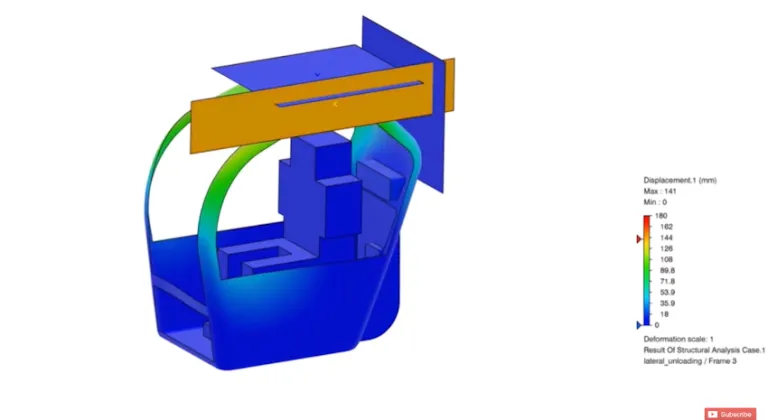

The Heavy Machinery Structural Engineering solution on the 3DEXPERIENCE platform offers an end-to-end structural and durability analysis tool. It streamlines simulations to identify product failures and minimize warranty costs across individual components and large assemblies, including welded structures, benefiting designers and engineers alike.

Full System Structural Integrity

Simulate variety of extreme operating cases, evaluating virtually the complete system ensuring structural integrity and stability in unfavorable and critical scenarios are met. Ultimately, Improving the design in holistic way, and reduce physical testing and cost.

Welded Structures Fatigue Assessment

Reduce physical testing and cost by gaining insights through simulation, identifying risks of welding failure, and improving the design to meet expected operation life. Supported by validated fatigue technology to increase the confidence in simulation based weld fatigue assessment, best-in-class general contact to enable seamless assembly setup and accurate/realistic simulation, and automated compatible weld mesh generation to speeds up modelling of large assemblies.

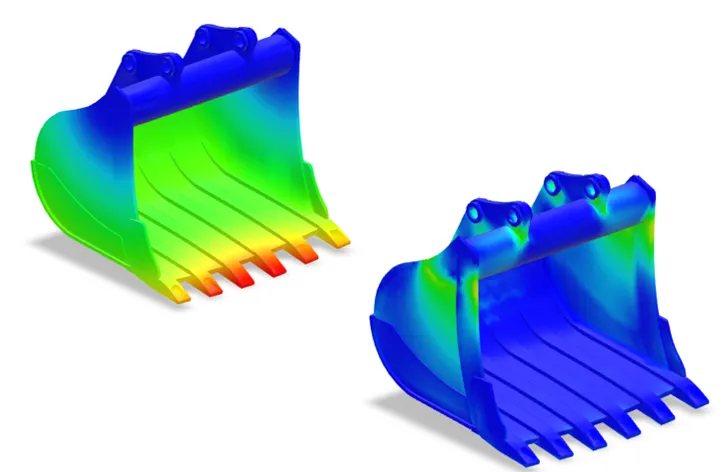

Component Strength and Durability

Reduce physical testing and cost by gaining insights through simulation, identifying risks of component failure under severe working conditions, and improving the design to meet expected operation life. Supported by best-in-class general contact to enable seamless assembly setup and accurate/realistic simulation.

Component Lightweighting

Empower designers with the expert capabilities to minimize part weight, maximize stiffness, reduce cost and optimize material usage. Designers must push past conventional ways of working to think outside the box. Innovating one concept at a time is no longer a sustainable method, Generative design is a new way to design lighter & stronger components. It allows to explore unimaginable shapes while respecting design specifications.

Heavy Machinery Operating Performance

The Heavy Machinery Operating Performance Industry Process Experience addresses the challenges of creating durable, high-performing heavy equipment in an evolving landscape marked by stricter regulations and the shift towards electrification.

This set of solutions is designed to optimize the lifespan and efficiency of machinery across farming, construction, and mining sectors, ensuring they meet contemporary operational demands.

Virtual Acoustic & Design Testing

Acoustic engineers have the ability to reliably assess the noise generated by operating systems (fan, exhaust, etc.), and correct potential issues, to ensure regulations are met before manufacturing a final physical prototype.

- Community noise

- Exhaust noise

- Fan noise

- Total noise (Fan + Engine + Exhaust)

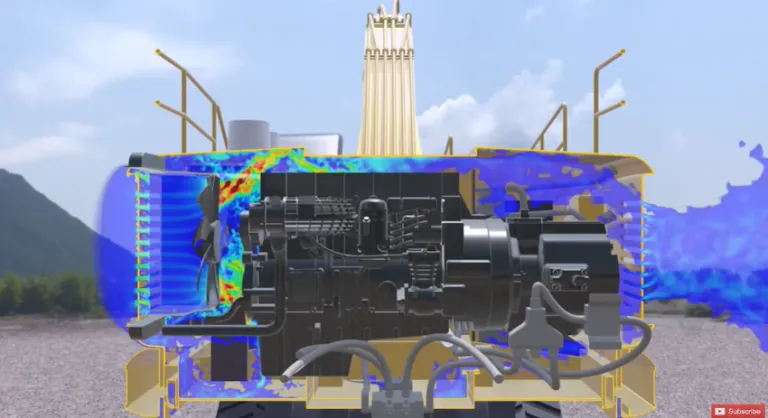

Thermal Management

In contrast to automobiles, these slow moving and stationary machinery do not have any “free” ram air to help with the cooling but rely solely on the performance of the cooling package including cooling fan(s) and heat exchangers to reject the excess heat. Thus, an effective cooling system is extremely important for them. Gradual heating is required to avoid thermal shock, and uniform cooling is crucial to prevent temperature spikes that can result In structural issues. In addition, there is strong need to ultilize digital solutions to meet engine certification requirements and reduce the tet failure risks.

Thermal engineers have the ability to leverage highly accurate simulation-driven design of cooling fan systems to ensure proper cooling airflow and to verify operating temperatures underhood in operating conditions, ensuring the final product will keep cool and be durable.

- Cooling air flow

- Thermal protection (Key-off/Soak)

- Thermal duty cycle

- Diesel exhaust fluid melting

Connectivity Performance

Antenna engineers ensure proper placement of antennas for best connection and minimum co-site interferences leveraging Dassault Systèmes’ electromagnetic solutions for antenna performance.

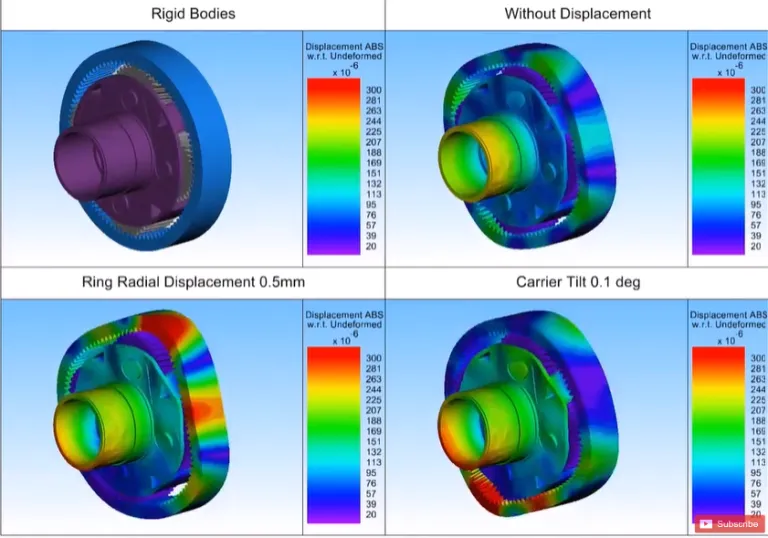

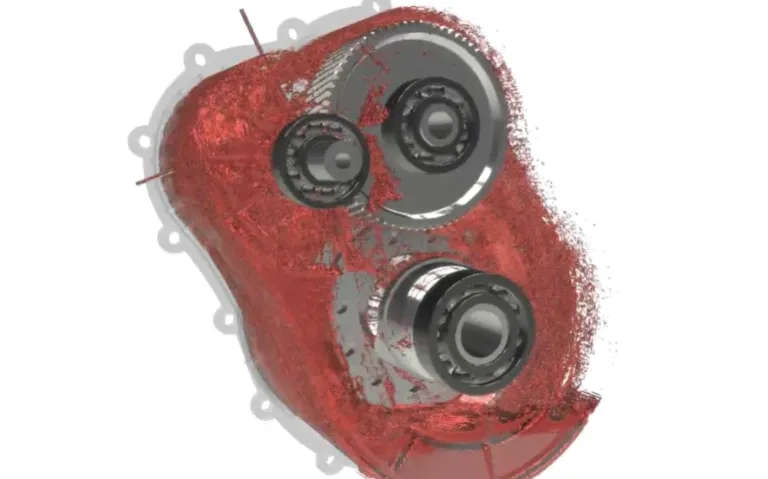

Drivetrain Performance

Gear module engineers use multibody simulation solutions for drivetrain dynamics to develop quiet, durable and high-performing drivetrain that provides the required power to run the machine smoothly.

- Noise & vibration

- Multibody system simulation

Material Handling & Tool Soil Interaction

Achieve maximum operating performance and minimum risk of failure, through fatigue by verifying ability to dig, plow, manipulate or transport material and soil with simulation of material transport on support structures.

Lubrication

Our GPU native solution empowers designers and analysts to perform complex Powertrain simulations, that involves multiphase flows and moving parts, such as Gearboxes, in a very fast and affordable way, without the significant hardware and long turnaround time that traditional CPU solutions required.

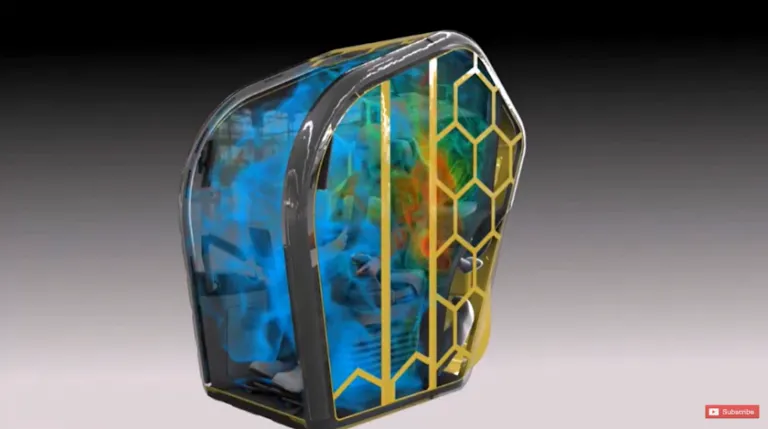

Heavy Machinery Safety & Comfort

Facing the challenge of operator fatigue, which incurs costs of $1200 to $3100 per employee annually according to the US National Health Council and heightens accident risks, manufacturers are now prioritizing cabin safety and comfort to enhance efficiency and reduce costs. Amidst intense market competition, technological innovations, and stringent regulations, Dassault Systèmes provides cost-effective solutions for designing next-generation cabins.

These solutions streamline the development process by reducing the need for costly prototypes and tests while ensuring the creation of superior operator experiences. By offering a comprehensive insight into cabin safety and comfort, these innovations enable manufacturers to make impactful improvements efficiently.

Thrown Object Protection Structures

Thrown object in injuries are the third leading cause of work related death. Strict regulations have been imposed to develop roll-over and thrown object structures. Besides ROPS certification, it is also important to keep operator comfort by creating spacious design with high visibility. Our workflow can assess the cabin and improve the structural performance with quick design change and updating FE models. Dynmaic explicit simulation helps in assessing impact of object.

Enhancing Thermal & Acoustic Comfort

A quarter of operators are expecting improved climate control performance. Our human-centric solutions maximize the thermal and acoustic comfort of the operator in any weather and environment, whilst ensuring maximum energy efficiency. These solutions focus both on high accuracy methodologies providing homologation quality results, and early stage topology optimization to explore hundreds of designs effectively.

- Cabin Noise, Vibration and Harshness

- Seat Comfort

- Cabin HVAC Noise

- Cabin thermal Comfort (Soak, Cooldown & Heat-up)

- Cabin Thermal Defrost

- HVAC System Performance

Limiting Specific Absorption Rate

- Electromagnetic and acoustics solutions are there to ensure that the operator stays safe and well isolated from worksite noise or concentrated radio fields. State of the art visuals provide you with the needed information to redistribute materials around the cabin to minimize acoustic transmission, or reposition shielding, antennas and cables to limit operator electromagnetic exposure.

Improving Rollover Protection Structures

- Our workflows leverage best-in-class implicit or explicit dynamics structural simulation to evaluate if rollover protective structures (ROPS) will meet the ISE 3471 standards. Our geometry tools take care of automatically updating CAD geometry and structural meshes to evaluate maximum load and crack propagation early in the design stages, and design safe and space efficient cabins.

Heavy Machinery Operating Performance

Stay competitive with through the Heavy Machinery Safety and Comfort workflows by :

- Accounting for diverse legislation through early stage digital pre-certification

- Reducing developments costs and cost of ownership

- Attracting operators and ensuring their safety and comfort

Heavy Machinery Electrification Engineering

The heavy machinery sector is rapidly adopting electric solutions to comply with global regulations, facing challenges such as high battery costs and limited testing data. To address this, batteries must be durable and perform well under extreme conditions while meeting emission and noise standards.

Through advanced simulation, we optimize battery cost, durability, and efficiency, and ensure safety and regulatory compliance under various stresses. This streamlined, multi-physics approach accelerates development and product market readiness.

Electric Drive Design & Performance

High power requirements, and harsh operating conditions, which leads to thermal management challenges. Leverage fully-parametrized models with automatic simulation scenario generation across physics. Minimize noise and failure risks through improved thermal management across operating conditions

- Design & thermal performance

- Gearbox lubrication

- Noise emissions

- Performance & trade-off analysis

Electric Machine Design

Complex multi-discipline system with conflicting design requirements. Stringent durability requirements for maintenance-free engines operating in harsh environment during long duty cycles & high cost of raw materials. Achieve high power density motors through the simulation of tightly-coupled multi-physics. Virtually test 1000s of insulation coverage scenarios through automated DOEs.

Heavy Machinery Electrification Engineering

Heavy machinery industry is rapidly transitioning to electric solutions due to increasing regulatory pressures globally. Hence there is pressure to market the products in a timely manner. The high battery cost with limited prior test data makes it challenging release the product in a given time. The battery packs used in the equipment must be durable and need to have longer life cycle whilst exposed to extreme conditions. Further there are stricter regulations for emission and noise levels and hence quite and efficient design are needed for extended duty cycle periods. In simulation, the battery cells and packs can be optimized to satisfy cost, durability & efficiency for different operating conditions and designs. We can also test the performance & safety of the battery pack and see if it passes legislation requirements under exposure to normal and extreme mechanical, thermal and electrical conditions. With our multi-physics, multi-scale capability we can solve the problem in different domains and development stages. Finally the solutions can be solved in single environment for most of the cases.

Battery Module & Pack

Battery Module Strength & Durability

- Battery module is normally comprised with several cells and envelope structure that holds, give stability and secures the cells. In order to design and evaluate the module structural soundness the interaction of main inner components and their attachment need to be considered.

- Detailed cell representation may increases dramatically the model size and computational time. With the Use Reduced-Order Cell Model to Improve Computational Efficiency Simulia solution can promote rapid design evaluation.

Battery Module Safety

- During the course of the module manufacturing, installation and operation, several handling, transportation and assembly conditions can be unintentionally cause safety concern. Cases of mishandling and drop impact, side impact or even punctuation of the module during the course of its usage are some scenarios.

Industry Processes for Heavy Mobile Machinery

Start Your Journey

The world of Industrial Equipment Engineering is changing. Discover how to stay a step ahead with SIMULIA.

Also Discover

FAQs about Heavy Mobile Machinery

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering