Tire Design & Simulation

Optimize tire performance with SIMULIA. From noise reduction to durability, leverage advanced simulations for smarter, faster, and cost-effective design.

What Are the Challenges in Modern Tire Design?

By 2030, vehicle miles traveled globally are expected to double to 20 trillion miles, driven by the rise of electric and autonomous vehicles. This surge in demand presents unique challenges for tire manufacturers:

- Adapting to new mobility trends like EVs and autonomous vehicles.

- Meeting stricter safety, durability, and efficiency standards.

- Reducing costs and time-to-market while fostering innovation.

To stay competitive, manufacturers must rethink their design processes and embrace advanced simulation technologies.

How Does Tire Simulation Solve Critical Design Questions?

When designing tires, manufacturers face key questions:

- How will the tires perform in extreme weather conditions, like wet or icy roads?

- How will they contribute to the vehicle's overall fuel efficiency?

- How long will they maintain optimal performance?

SIMULIA’s tire simulation solutions provide precise answers to these questions, empowering manufacturers to make data-driven decisions early in the design process.

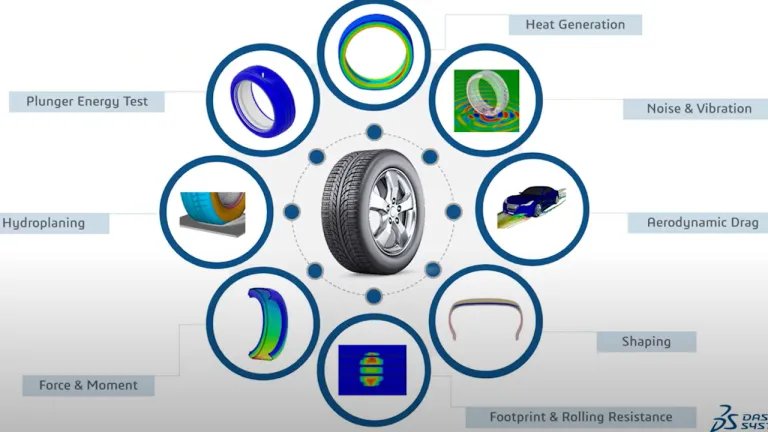

Why Is High-Fidelity Tire Simulation a Game-Changer?

High-fidelity tire simulation is revolutionizing the industry by enabling manufacturers to:

- Push the boundaries of the 'Magic Triangle'—safety (wet grip), durability (wear resistance), and efficiency (rolling resistance).

- Save time and costs by reducing reliance on physical prototypes.

- Meet SAE testing standards with advanced physics-based simulations.

With these capabilities, manufacturers can innovate faster and deliver better-performing tires to market.

Key Benefits of SIMULIA Tire Design & Simulation Solutions

Collaboration

Integrate data and eliminate silos among stakeholders.

Democratization

Enable easy use of simulation tools for all users.

Sustainability

Minimize waste by exploring materials early in development.

Cost Savings

Cut costs and time by using virtual twins to avoid late-stage changes.

Risk Mitigation

Validate performance through simulation before physical testing.

Innovation

Assess new ideas early using DoE to explore design possibilities.

SIMULIA Customers References in Tire Engineering

Optimize Road-Load Prediction with High-Fidelity Simulation

Driving the Future of Mobility with CASE

By 2030, global vehicle miles traveled are projected to double to 20 trillion, fueled by the rise of CASE (Connected, Autonomous, Shared, Electric) mobility. This shift is increasing shared vehicle utilization, even as new vehicle sales decline.

To stay ahead, Tire and Vehicle OEMs must:

- Meet evolving customer demands.

- Optimize supply chains and raw material usage.

- Accelerate innovation while reducing production costs to boost margins.

How the Tire Vehicle Simulation Solution Helps

SIMULIA’s Tire Vehicle Simulation (TVS) solution empowers OEMs to meet regulatory demands and optimize performance with cutting-edge capabilities:

- Meet NHTSA Performance Requirements:

Conduct full vehicle dynamics simulations and component response analyses to ensure compliance with safety standards. - Achieve Aerodynamic Drag Compliance (WLTP):

Lower aerodynamic drag to meet Worldwide Harmonized Light Vehicles Test (WLTP) standards, saving $10 per extra drag count. - Enable Virtual Tire Submission:

Facilitate IP-controlled exchanges and create reduced-order tire models for dynamic evaluations. Includes tire reverse engineering when direct exchanges are not feasible.

Why Choose SIMULIA’s TVS Solution?

- Regulatory Compliance: Stay ahead of global safety and efficiency standards.

- Cost Savings: Reduce late-stage design changes and optimize production costs.

- Innovation Acceleration: Leverage high-fidelity simulations to innovate faster and smarter.

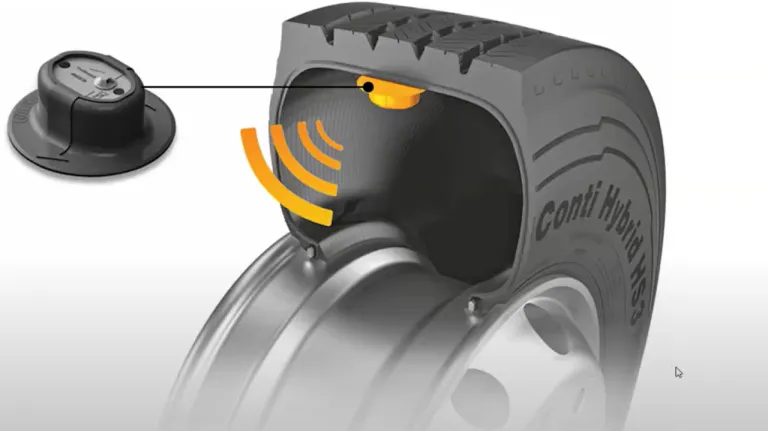

Predictive Durability with Intelligent Tires

Intelligent tires, equipped with integrated sensors, now enable accurate durability predictions by combining loading history (via Simpack) and tire performance (via Abaqus). These sensors monitor:

- Load & Strain: Real-world force measurements.

- Temperature: Overheating detection to prevent failures.

- Tire Pressure: Real-time monitoring for safety and performance.

This predictive approach revolutionizes tire design and longevity.

Durability Enhancement

Virtual durability models provide critical insights into a tire's remaining useful life by simulating long-term effects of loading history.

Key Capabilities:

- Structural Integrity Analysis:

- Predicts fatigue damage in internal components like belt plies and sidewall reinforcements.

- Forecasts the likelihood of structural failure over time.

- Tread Wear Simulation:

- Estimates tread wear rates based on usage patterns.

- Provides accurate predictions of remaining tread life.

- Grip Performance Prediction:

- Evaluates current and future grip as the tread wears down.

Why it matters:

- Optimize replacement cycles for cost efficiency.

- Enhance safety for drivers and fleet operators.

- Reduce operating costs with better decision-making.

This comprehensive approach ensures safer, longer-lasting, and more cost-effective tire performance.

Predictive Maintenance

Virtual tire modeling within a digital twin framework revolutionizes tire health monitoring and prediction. A digital twin is a virtual representation of a physical asset, in this case, a tire.

Key Capabilities:

- Digital Twin Simulation:

- Uses real-world data (pressure, temperature, speed, road conditions) to replicate tire performance.

- Predicts the tire's current health state and life expectancy.

- Stress and Strain Analysis:

- Identifies weak points and accelerated aging in the internal structure.

- Detects hidden issues invisible to the naked eye.

- Proactive Maintenance Alerts:

- Warns of potential failures before they occur.

- Enables timely interventions to prevent catastrophic damage.

Why It Matters:

- Enhances Safety: Prevents unexpected tire failures.

- Extends Tire Life: Optimizes maintenance schedules for longer operational use.

- Reduces Costs: Minimizes downtime and operating expenses for fleet managers.

This predictive approach ensures safer, longer-lasting, and more reliable tire performance.

Predictive Modeling

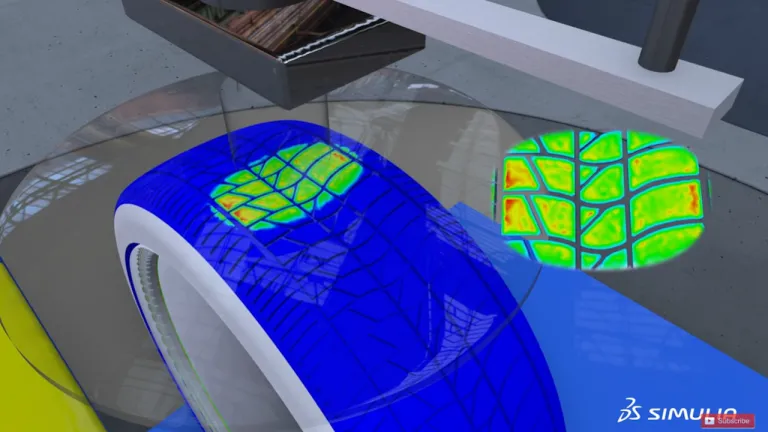

Accurately predicting tire performance using the finite element method (FEM) delivers significant value in tire design and development.

Key Capabilities:

- High-Fidelity Digital Models:

- Analyze and optimize performance characteristics before building physical prototypes.

- Evaluate footprint shape and pressure distribution for better handling, grip, and wear.

- Dynamic Behavior Simulation:

- Predict forces and moments during cornering, acceleration, and braking.

- Forecast rolling resistance for improved fuel efficiency.

- Simulate radiated noise from tire-road interaction to meet regulations and enhance comfort.

Why It Matters:

- Reduces Development Time: Enables rapid iteration and optimization of designs.

- Cuts Costs: Minimizes reliance on physical prototypes.

- Improves Performance: Ensures better handling, efficiency, and compliance with standards.

This virtual approach accelerates innovation while ensuring high-performance, cost-effective tire designs.

Minimize Pass-By Noise with Advanced Simulation

Tackling Noise Challenges in the EV Era

With the rise of electric vehicles (EVs), tires have become a primary source of radiated noise. Tire-induced noise can be categorized into two types:

- Pass-By Noise: Travels through the air, affecting people outside the vehicle.

- Interior Noise: Travels through the vehicle structure, impacting passengers inside the cabin.

End-to-End Noise Simulation with SIMULIA

At Dassault Systèmes, we offer an E2E (end-to-end) process that empowers tire manufacturers to:

- Assess the impact of tire construction, material selection, and pattern geometry on radiated pass-by noise.

- Leverage realistic virtual testing with a combination of Tread Meshing, Abaqus, and wave6 for best-in-class modeling, simulation, and post-processing.

Exceed Industry Standards with Confidence

Our advanced simulation technology helps you:

- Minimize late-stage design changes, saving time and costs.

- Meet and exceed industry regulations, such as WLTP for radiated noise levels.

- Deliver quieter, more efficient tires for the EV market.

Tire Footprint

Footprint Shape: Predicting the contact patch geometry precisely is crucial for understanding how the tire interacts with the road. Virtual prediction allows for rapid iteration and optimization of tread patterns and tire construction to achieve desired shapes (for example, more rectangular for better grip or specific shapes for noise reduction).

Footprint Pressure Uniformity: Non-uniform pressure distribution within the footprint can lead to uneven wear, reduced grip, and unpredictable force and moment generation. Virtual tools can simulate and optimize the design to achieve a highly uniform pressure distribution, thereby enhancing:

- Force and Moment Generation: A uniform footprint pressure leads to more consistent and predictable lateral and longitudinal forces, improving vehicle handling, braking, and acceleration.

- Wear: Even pressure distribution directly translates to even tread wear, extending tire life and reducing operational costs. Virtual prediction allows for optimizing designs to mitigate hot spots and areas of high stress, which are precursors to accelerated wear.

Cleat Impact

Automated virtual prediction of cleat impact is invaluable for assessing tire durability and ride comfort. Key aspects include:

- Importance of Material Damping: Virtual simulations accurately model the viscoelastic properties of tire materials. This is crucial for predicting how the tire absorbs and dissipates energy upon impact with an obstacle like a cleat. High material damping leads to:

- Associated Force Decay: A faster decay of impact forces after the tire engages the cleat. This is vital for reducing shock transmitted to the vehicle and occupants, improving ride comfort, and minimizing stress on suspension components. Virtual prediction allows for material selection and design optimization to achieve optimal damping characteristics.

Pass-by Noise

Virtual prediction of pass-by noise is increasingly critical due to stringent regulatory demands and consumer expectations for quieter vehicles. Its value lies in:

- Importance of Tread Design: Tread patterns are a major contributor to tire noise. Virtual tools enable designers to experiment with different groove geometries, sipe designs, and block arrangements to minimize air pumping, pipe resonance, and tread impact noise. This iterative virtual optimization is far more efficient than physical prototyping.

- Importance of Material Damping: Just as with cleat impact, the damping properties of tire materials influence noise generation, particularly in absorbing vibrations that contribute to structure-borne noise. Virtual simulation can guide the selection of materials with optimal damping characteristics to reduce overall noise levels.

- Impact of Emerging Regulatory Requirements (for example, WLTP in Europe): Global regulations like the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) in Europe are imposing stricter limits on vehicle noise. Virtual prediction allows manufacturers to design tires that inherently meet these evolving standards, avoiding costly redesigns and delays associated with failing physical tests.

Structural Antenna Engineering

The integration of antennas within tires and their virtual prediction offers transformative value for smart tire technologies:

- Telemetry from the Antenna:

- Tire Identification (RFID): Embedded RFID tags enable unique tire identification, streamlining logistics, inventory management, and traceability throughout the tire's lifecycle. Virtual prediction ensures reliable signal transmission and reception for this purpose.

- Tire Health (Using Acceleration Telemetry to Predict Remaining Life): Accelerometers embedded in tires can provide real-time data on tire deformation, vibrations, and impact events. Virtual prediction helps optimize sensor placement and antenna performance to transmit this telemetry accurately. This telemetry can then be used to predict remaining tread life, detect anomalies (for example, uneven wear, impending blowouts), and optimize maintenance schedules.

- Antenna Read Distance: Virtual simulation allows for optimizing antenna design and placement within the tire to maximize read distance, which is crucial for efficient data capture in various operational scenarios (for example, drive-through readers at service centers).

- Antenna Durability: Tires operate in harsh environments. Virtual prediction can simulate the stresses, strains, and temperatures experienced by the embedded antenna, ensuring its long-term durability and functionality without compromising tire integrity.

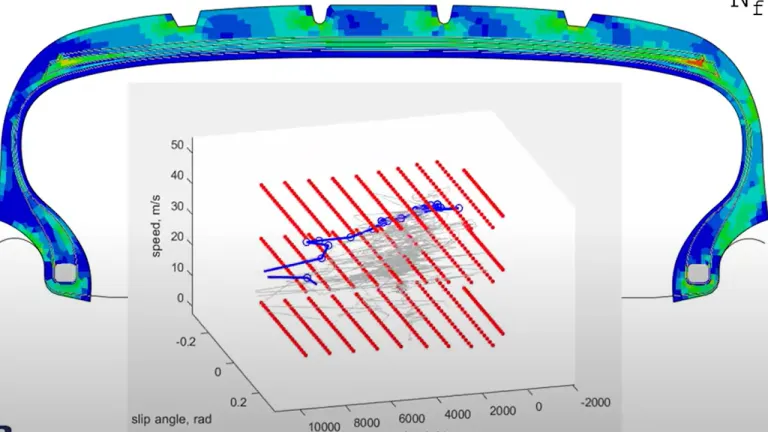

Vehicle Performance Prediction

This approach enhances vehicle handling, stability, and ride comfort through:

- Advanced Tire Design in CATIA: Use power copies and UDFs to create complex, parametric tire designs. Rapidly modify tread patterns, sidewalls, and structures by adjusting input parameters, speeding up design iterations and optimization.

- Reduced-Order Tire Models (ROMs): Simplify high-fidelity Abaqus FE models into ROMs for real-time vehicle dynamics simulations. These models predict performance under dynamic conditions (e.g., cornering, braking) and integrate into MBS tools, reducing reliance on physical prototypes.

- AI for Tire Optimization:

- Tire Size Expansion: AI leverages existing data to suggest optimal designs for new sizes, cutting manual effort.

- Pareto Front Analysis: AI identifies optimal trade-offs (e.g., grip vs. wear) to guide engineers in selecting the best designs based on multiple performance criteria.

This integrated approach accelerates development while reducing costs and time.

Tire Shaping

Virtual tire shaping plays a critical role in ensuring manufacturing quality and consistent performance.

- Optimization of TBM Parameters: Simulations of Tire Building Machine (TBM) settings, including ply angles, cord tension, and component placement, enable engineers to refine their processes. This ensures the green tire’s geometry and internal structure meet performance requirements like uniformity, balance, and rolling resistance.

- Defect Prediction: Virtual shaping identifies potential manufacturing issues, such as wrinkles, overlaps, or poor adhesion, enabling proactive adjustments to prevent defects.

- Green vs. Cured Tire Shapes:

- Green Tire Shapes: Simulating the shapes of individual components (plies, belts, tread) before assembly ensures accurate modeling of the shaping process.

- Cured Tire Shapes: Simulating vulcanization accounts for material transformations and shrinkage, enabling precise predictions of final tire geometry and performance.

By integrating virtual shaping into the design and manufacturing workflow, engineers can streamline processes, reduce iteration cycles, and deliver high-quality, predictable tires.

SIMULIA Industry Process Experiences for Tire Engineering

Start Your Journey

FAQs about Tire Design & Simulation

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering