Polymers & Composites

Driving the Design of Advanced Composites and Polymers

Composites Innovation: Atomic Insights, Major Impact

Materials such as carbon fiber reinforced polymers (CFRPs) provide the tremendous strength-to-weight ratio needed for use in aircraft, space satellites, wind turbines, sports cars, subsea oil production and sports equipment. But their use is constrained by manufacturing costs, so cheaper glass filled composites are used in less demanding applications. Another challenge is sustainability: at end-of-life, the fibers are difficult to extract and recycle. Rubber compounds are another major composite material, where researchers are trying to optimize the formulation, fillers and additives to improve tire wear, traction and rolling resistance.

Advanced composites is a competitive space for innovation in manufacturing costs, material strength, density, durability, moldability, adhesion, sustainability and much more. These issues can be uniquely addressed by exploring the atomic interactions of the constituent materials involved using modeling & simulation.

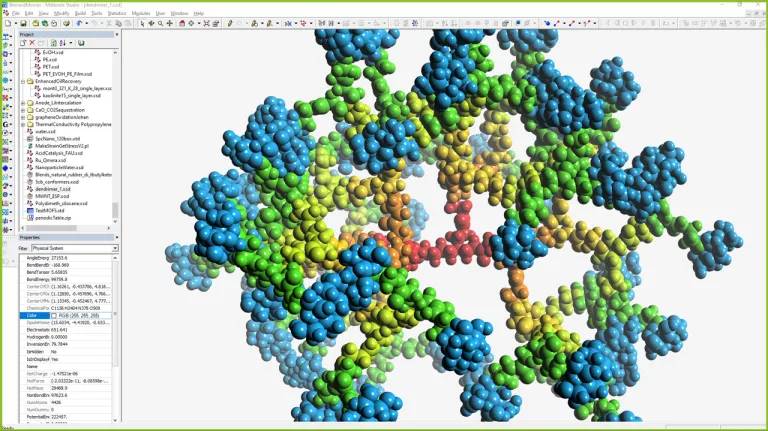

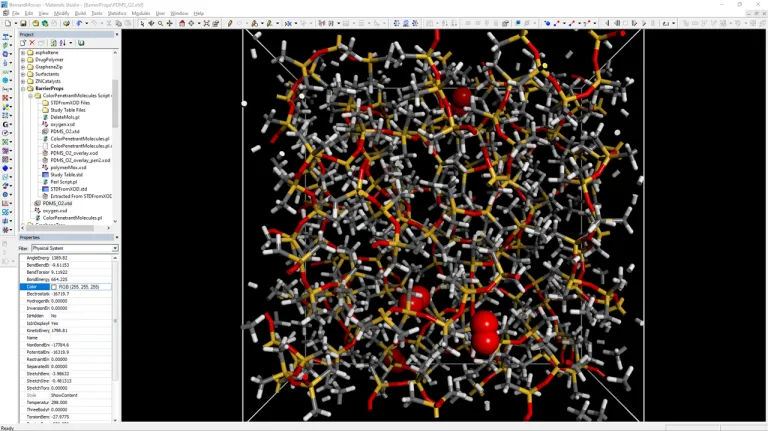

BIOVIA Materials Studio accelerates the design and development of polymer composite materials by providing insight into the behavior of these materials in silico.

- Polymers

- Composites

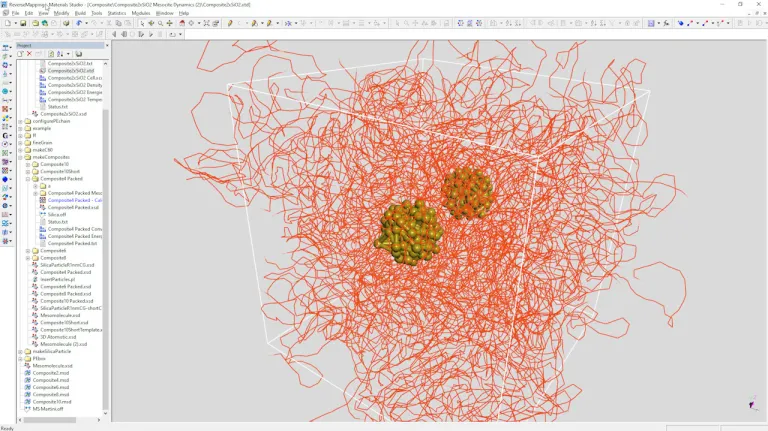

- Multiscale Modeling

Polymers

- Predict the behavior of pure polymers and their properties such as glass transition temperature (Tg), Young’s modulus, yield stress and critical strain

- Crosslink simulation to understand polymer network formation and impact of chemical structure, additives and processing on mechanical properties and Tg

- Calculate reaction energies and kinetics for polymerization and degradation reactions

- Explore catalyst features such as stereochemical selectivity

- Predict thermodynamic properties with BIOVIA COSMOtherm

- Use Quantitative Structure-Property Relationship (QSPR) models to correlate polymer repeat unit structure with bulk properties such as Tg, Poisson’s ratio, thermal conductivity, refractive index, fracture stress and permeability

Composites

- Cohesive strength and mechanical failure of the polymer-filler interface

- Screen sizing agents for production of carbon fibers of desired shape and size

- Simulate crosslinking of resin around the fibers and characterize the structure and binding strength

Multiscale Modeling

- Simulate polymer microstructure via coarse grained simulation such as microdomains that form in block copolymers or with addition of thermoplastic tougheners

- Predict the ideal formulations of polymer blends with native machine learning methods and multi-objective optimization workflows

- Export structures and parameterize SIMULIA Abaqus RVE models to simulate full composite and parts

Explore Our Methods

The world of Polymers & Composites is changing. Discover how to stay a step ahead with BIOVIA

Join the conversation in the BIOVIA Materials Studio User Community!

Also Discover

Learn What BIOVIA Can Do for You

Speak with a BIOVIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right BIOVIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering