Systems Engineering

End-to-End Model-Based Solutions for Mechatronics & Software-Driven Experiences

Virtual Twin Experience from Mission to Certification

Industries are increasingly adopting Systems Engineering to face unprecedented product complexity with highly regulated and competitive environments. From automated driving to smart building to medical devices, Model Based Systems Engineering (MBSE) is becoming the best practice to deliver mission-critical systems composed of mechatronics and software. MBSE enables to analyze users and stakeholders needs, design, simulate and optimize the best solution, from its mission to certification and retirement

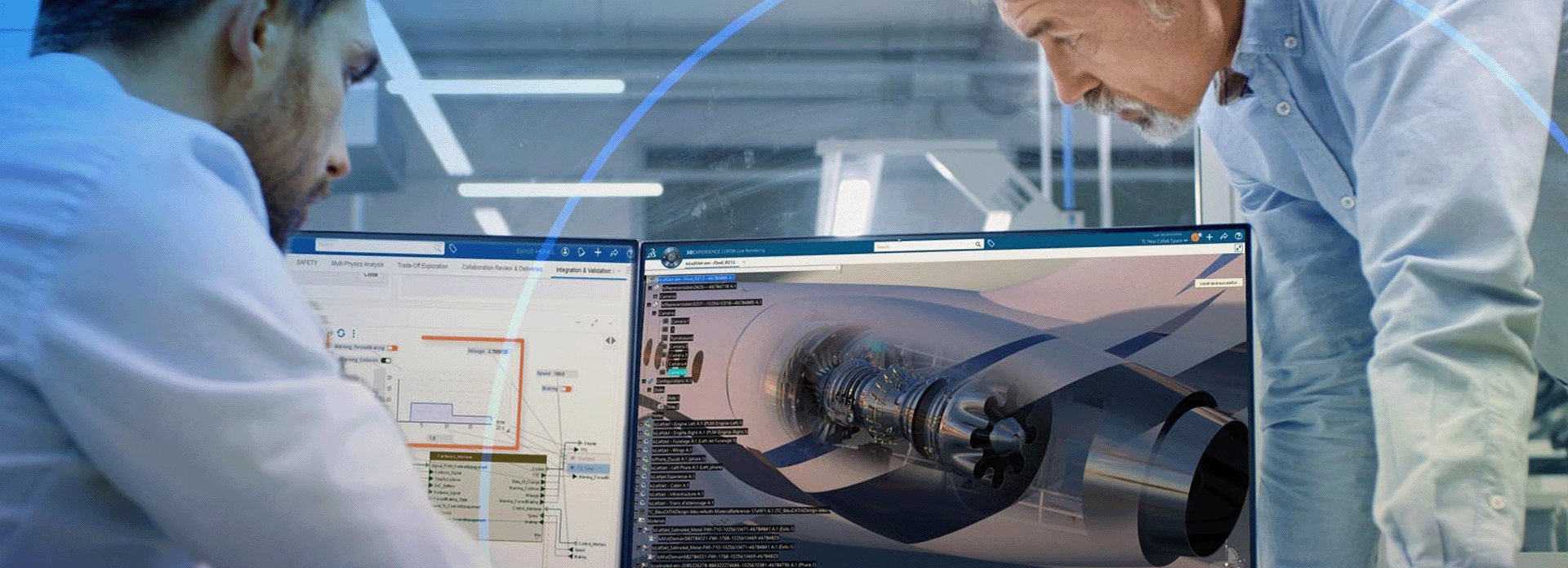

Dassault Systèmes solutions integrates requirements, systems architecture, cross-disciplinary modeling & simulation – including embedded software, validation & verification into one unified, collaborative and open environment. End-to-End traceability and change management support agile informed-decisions and ease the compliance to quality and certification standards.

CATIA Systems Engineering Key Benefits

Speed-up Time to Market Agility

Analyze stakeholders needs and study best solutions trade-off thanks "what-if" analysis and simulation

Anticipate Risks Better and Quicker

Take informed decision to identify change impact across disciplines and define best make / buy / reuse strategies

Improve Quality and Reduce Costs

Detect integration errors and decrease physical testing cost thanks to Virtual Prototyping and Simulation

Comply to Market Requirements & Regulations

Manage end-to-end traceability and changes from requirement to hardware/software deliveries

Leverage Standards & Openness

Accelerate MBSE adoption thanks to standards support (UAF, SysML, Modelica, FMI, Autosar, and more)

Explore the Systems Engineering Subdisciplines

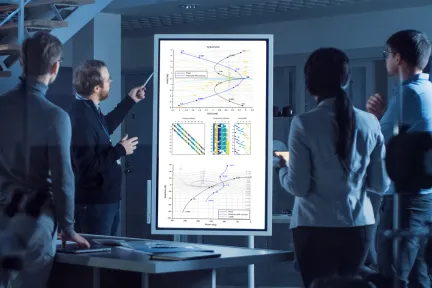

Analyze Stakeholders Needs & Requirements to Specify and Simulate Best Solutions Trade Off

Ensure Product Design Consistency across Disciplines, Leveraging Modeling and Simulation

Continuously Integrate, Test & Validate Embedded Software & Systems to Manage End-to-End Traceability

A Comprehensive Set of End-to-end MBSE solutions

Systems Engineering solutions are built on industry-proven solutions (CATIA Magic, Dymola, ControlBuild, Stimulus, CATIA SCANeR) and integrated into the 3DEXPERIENCE platform, enabling an unified & collaborative environment from Requirements to Systems Design to Virtual Validation & Test. Thanks industry standards support and tools openness, the solutions are modular, from point solution quick adoption to a full enterprise-level implementation.

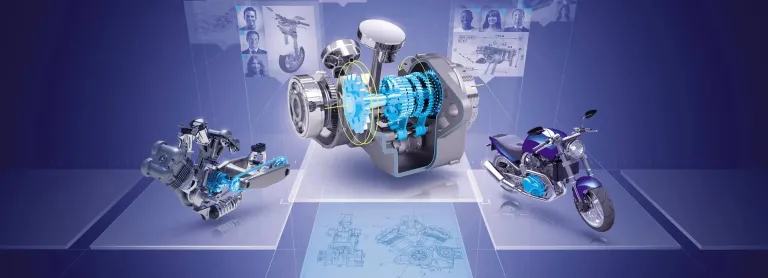

Our software solutions are currently empowering professionals across a diverse range of industries, including Aerospace & Defense, Transportation & Mobility, Industrial Equipment, High-Tech, Infrastructure & Cities and Life Sciences industries. These solutions provide comprehensive support for Systems Engineering and Model-Based Systems Engineering (MBSE) practices to facilitate:

- Systems & Disciplines Modeling and Simulation

- Support all stages of system engineering development- from initial concept through design, analysis, verification, and validation, to the end of the product lifecycle.

- Integrate multiple-discipline within the context of the system to streamline interface management, predict system behavior, and accelerate the convergence of hardware and software design.

- Virtually experience a virtual replica of the system, anytime in the process, enhancing solution optimization and decision-marking

- Systems Federation & Openness

- Enable the integration and federation of systems engineering data across different authoring tools. This ensures end-to-end traceability for easier compliance assessment and efficient impact analysis when engineering changes occur.

- Embrace industry standards to support tools interoperability for semantic integrity and exchanges in extended enterprise context

- Systems Governance: In a regulatory context, the capability to maintain in configuration, a centralized, authoritative single source of truth for compliance assessment. It provides full control over systems engineering activities throughout the project, ensuring effective governance and management.

CATIA Systems Engineering Roles

CATIA Systems Engineering software products are packaged as Roles on the 3DEXPERIENCE platform to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

Explore Other Products

Start Your Journey

Systems Engineering FAQs

Systems engineering is important because it helps manage complexity, fosters interdisciplinary collaboration, mitigates risks, optimizes resources and performance, considers the entire lifecycle of a system, aligns solutions with stakeholder needs, and promotes innovation and adaptability. It ensures the successful development and operation of complex systems across various domains.

Systems engineering techniques are used in complex projects: printed-circuit-board design, robotics, bridge building, software integration, and spacecraft design. But also in :

- Aerospace: Designing and developing aircraft or spacecraft systems, including avionics, propulsion, and navigation systems, to meet performance, safety, and reliability requirements.

- Automotive: Integrating various subsystems within a vehicle, such as engine, transmission, braking, and electrical systems, to ensure optimal performance, fuel efficiency, and safety.

- Information Technology (IT): Designing and implementing complex IT systems, networks, and software architectures to support organizational operations, data management, and communication needs.

- Healthcare: Developing and integrating medical devices, electronic health record systems, and telemedicine platforms to improve patient care, efficiency, and healthcare delivery.

- Energy: Designing and optimizing energy systems, such as power plants, renewable energy systems, and smart grids, to ensure reliable and sustainable energy production and distribution.

- Transportation: Planning and implementing transportation systems, including highways, railways, and urban transit systems, to facilitate efficient and safe movement of people and goods.

- Defense and Security: Developing integrated defense systems, including command and control systems, surveillance systems, and missile defense systems, to protect national security interests.

- Building and Infrastructure: Infrastructure systems involves the design, analysis, and management of infrastructure supporting human activities, including, for example, electric power, oil and gas, water and wastewater, communications, transportation, and the collections of buildings that make up urban and rural communities.

- Product Systems Engineering: Focuses on the design and development of individual products, ensuring they meet customer requirements and perform effectively.

- Enterprise Systems Engineering: Deals with the integration of multiple systems within an organization, ensuring they work together efficiently to achieve overall business performance and objectives.

- Service Systems Engineering: Concentrates on designing and improving service-oriented systems, such as IT infrastructure or transportation networks, to deliver high-quality services to customers or users.

A system engineer designs, integrates, and tests complex systems, ensuring they meet requirements and function properly. They manage and monitor all installed systems and infrastructure, also, risks, document processes. The role of system engineer is essential in ensuring the successful development, performance and operation of complex systems.

Here are the main differences between system engineering and MBSE:

- System engineering is a holistic approach to designing and managing complex systems, focusing on requirements, architecture, integration, and maintenance.

- Model-Based Systems Engineering (MBSE) is the formalized application of modeling to support system requirements, design, analysis, verification and validation activities beginning in the conceptual design phase and continuing throughout development and later life cycle phase.

Industrial and systems engineering (ISE) intersects with various fields, including engineering disciplines like operations research, management science, supply chain management, manufacturing, quality engineering, human factors engineering, and data analytics. It applies principles and methods from these areas to optimize systems, processes, and operations in diverse industries.

Join the conversation in the CATIA MBSE Cyber System User Community!

Also Discover

Learn What CATIA Can Do for You

Speak with a CATIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right CATIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering