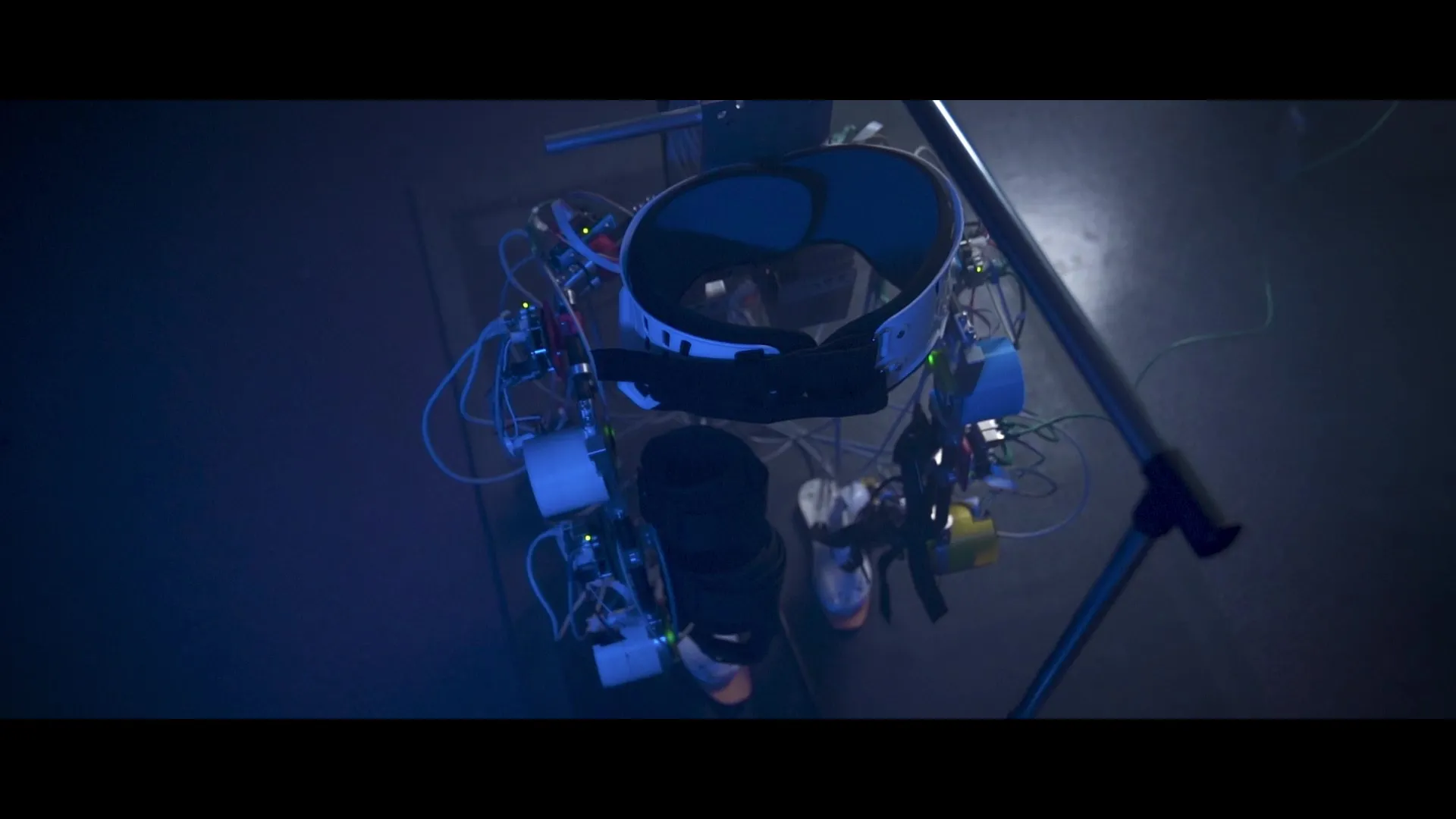

Create a motion exoskeleton project

Discover how Junia/HEI creates an exoskeleton project with Get it Made via the 3DEXPERIENCE Make on-demand manufacturing service.

What is the project?

USAGE

Reflecting on how we could help children walk again gave birth to this motion exoskeleton project.

MATERIAL

Metal - Aluminum

PROCESS

CNC Machining - Subtractive: Milling

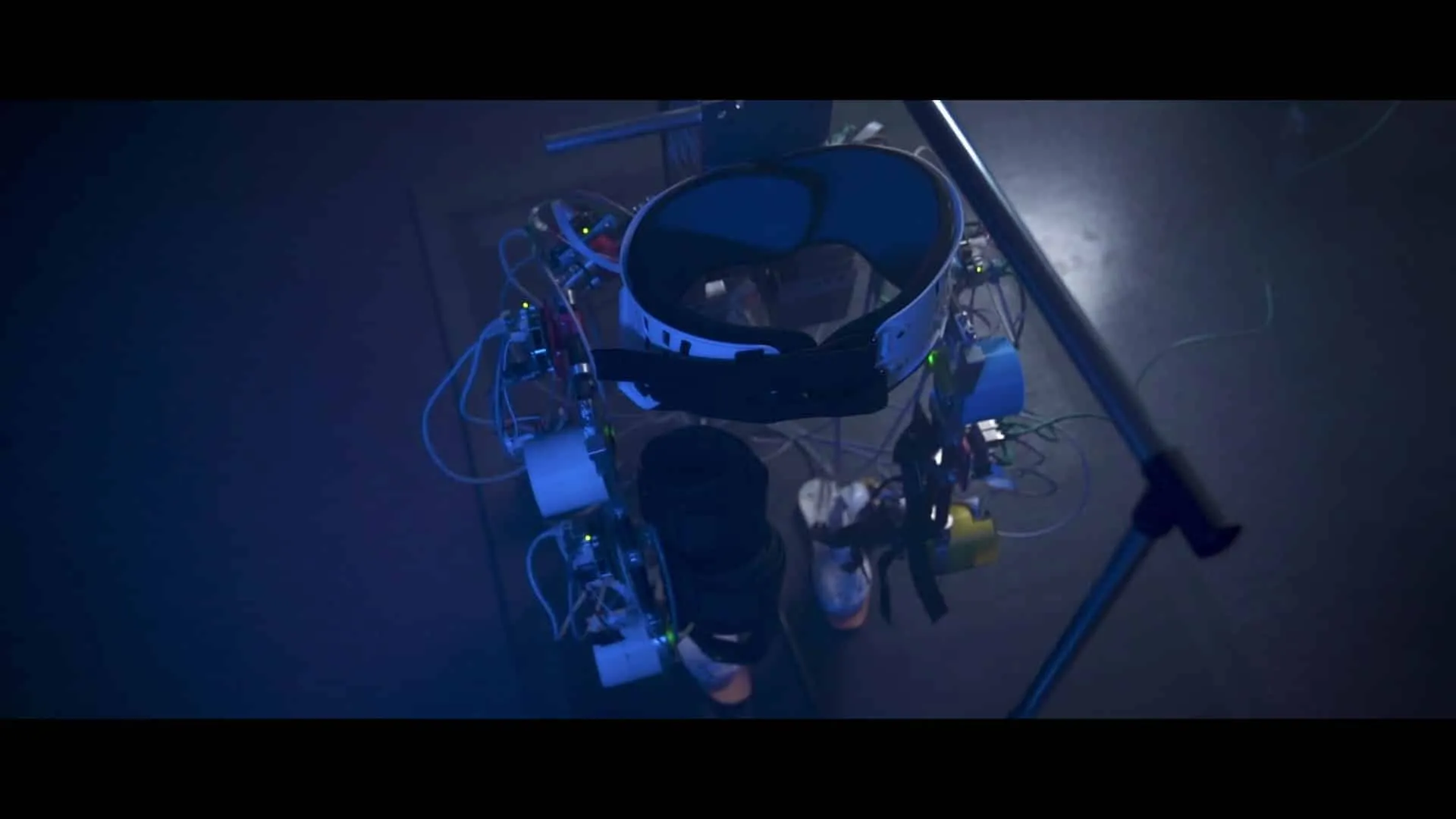

What does the Junia/HEI project look like?

Feedbacks from Junia/HEI

Why did you start this project?

A few years ago, the father of a disabled child came to see us because he wanted his daughter to be able to walk. Reflecting on how we could help this child walk again gave birth to this motion exoskeleton project.

What is an exoskeleton?

An exoskeleton is a mechanized structure worn on the person’s limbs. This structure can be used either to amplify a movement, for example, for carrying heavy loads or in the case of a disabled child, it is to re-imprint the movement that is being prevented by the disability.

How do you design your exoskeleton?

To create the exoskeleton structure, we put together a working group with technicians, mechanical and biomechanical engineers, and clinicians using the SOLIDWORKS software to define all the exoskeleton parts.

How do you find 3DEXPERIENCE Make the on-Demand manufacturing service?

In SOLIDWORKS, we have a module that allows direct access to the 3DEXPERIENCE Marketplace. We can choose the part to manufacture and machine tool it very easily. Once the parts were validated in 3D printing, we used the 3DEXPERIENCE Marketplace Make service to get all the exoskeleton parts machined.

What are the benefits of this platform?

The advantage of this service is that it is online. We were able to communicate our plans directly through the platform. This whole service allowed us to manufacture all the parts of our exoskeleton at once for a relatively competitive cost.

When we do the project, sometimes we need to machine metal parts. But as students, we don’t have much connection with manufacturing companies. With the Make service on the 3DEXPERIENCE Make Marketplace, we can choose manufacturers worldwide and manufacture our project parts very quickly. As a result, we received all the parts in only two to three weeks. For now, we’ve assembled all the parts. We have put all the motors on the exoskeleton and all the control boards, and we can now set up walking trajectories for our structure.

The buyer and the manufacturer

Junia/HEI

The teacher-researchers are working on this research project: an exoskeleton for children with cerebral palsy who cannot walk.

Get It Made

Your manufacturing partner for CNC manufacturing, prototyping and production of custom parts. Your project is unique, and we deliver the service it demands.

Discover our other manufacturing services

3D Printing - Additive manufacturing

FDM, SLS, MJF, BJ, SLA...

(Milling, turning & spark machining)

CNC Machining - Substractive

Milling, turning & spark machining

Cutting

Laser cutting, Water cutting, Blade

Sheet Metal

Get multiple quotes for your parts in seconds