Composite manufacturing

Upload your design, get your composite manufacturing quote, choose your manufacturer and receive your parts!

SECURE PAYMENTS

Via payment card or purchase order

PROTECTED IP

Your data is confidential and secure with us. Use your own Non Disclosure Agreement

INSTANT QUOTE

For 3D Printing and CNC Machining, get quote in few seconds.

Composite manufacturing with 3DEXPERIENCE Make

From plywood to aircraft wings, composites can be found throughout modern society and are increasingly being used in place of traditional materials like wood and metal.

For millennia, humans have been combining different materials to create something that is more durable, flexible and capable than their constituent parts.

Composite manufacturing dates back to ancient brick-making when straw was added to wet clay or mud to accelerate the drying time and provide a stronger finished brick. Metal reinforcement bars in concrete structures perform much the same function. Concrete, the second most used material in the world after water, is itself a composite of loose stones and cement.

The primary reason for making composites is enhanced strength, as in the examples above, but it’s not the only one. For instance, a composite material may be less expensive, lighter, water and heat-resistant, more rigid, electrically conductive or a combination.

Modern composites have been designed to fulfill a specific need and are routinely used in industries such as aerospace, automotive, defence, marine, medical devices and sports equipment.

Common examples include engineered wood, carbon fiber, fiberglass, fibre-reinforced plastics and advanced ceramics. The list of composites is constantly growing as researchers experiment with different material combinations and develop new varieties, processes and applications.

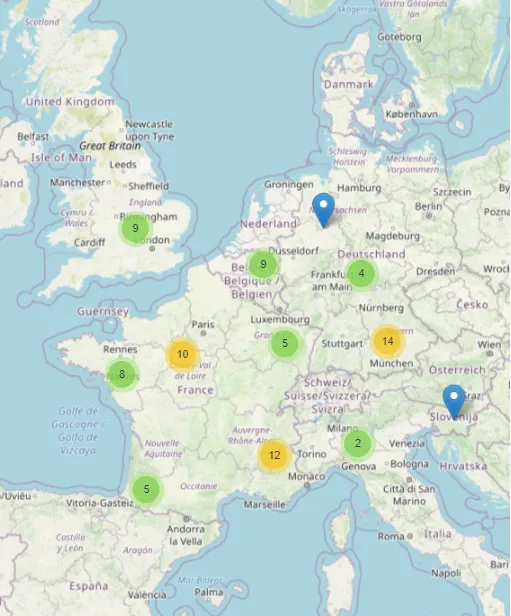

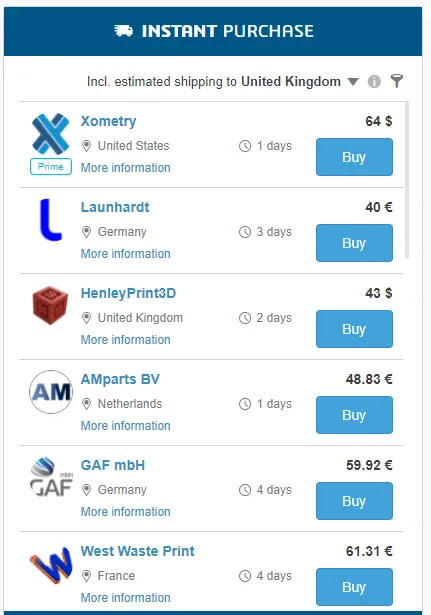

On 3DEXPERIENCE Make, we offer composite manufacturing options across multiple processes such as 3D printing, CNC machining service, Laser cutting service and Injection molding service. 3DEXPERIENCE Make is an On-Demand Manufacturing platform, which connects designers or engineers with industrial service providers. Our service providers are mostly based in North America (United States and Canada) and in Europe (United Kingdom, France, Netherlands, Germany etc...).

Thanks to our powerful algorithm, you can get quotes in seconds for your composite project from dozens of manufacturing providers.

Our network of composite manufacturing providers

United States

Canada

United Kingdom

France

Germany

Netherlands

and many more...

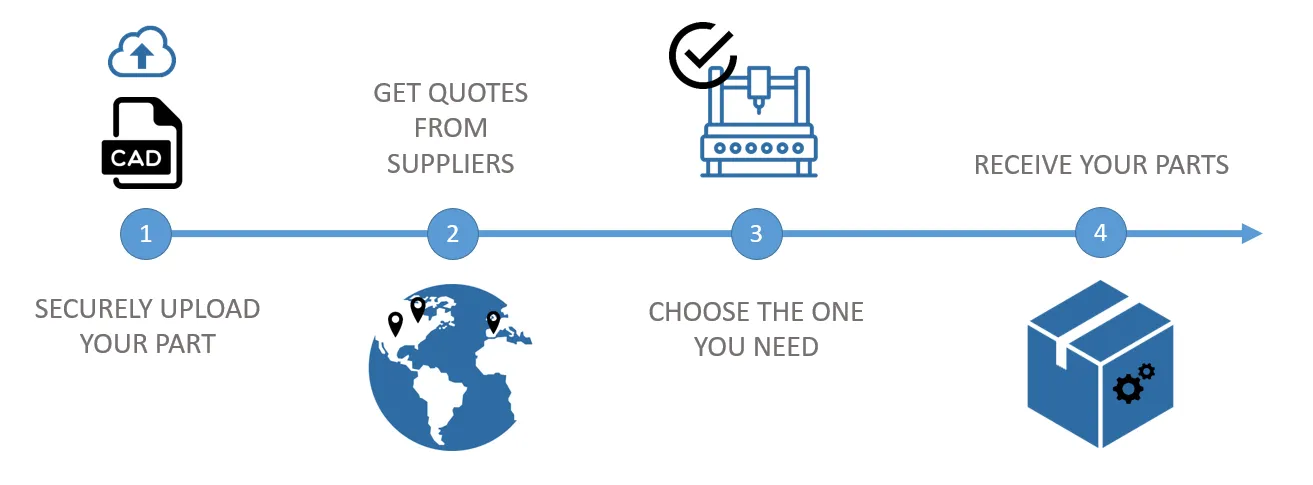

Online manufacturing service: how does it work?

Composite materials available with our service providers

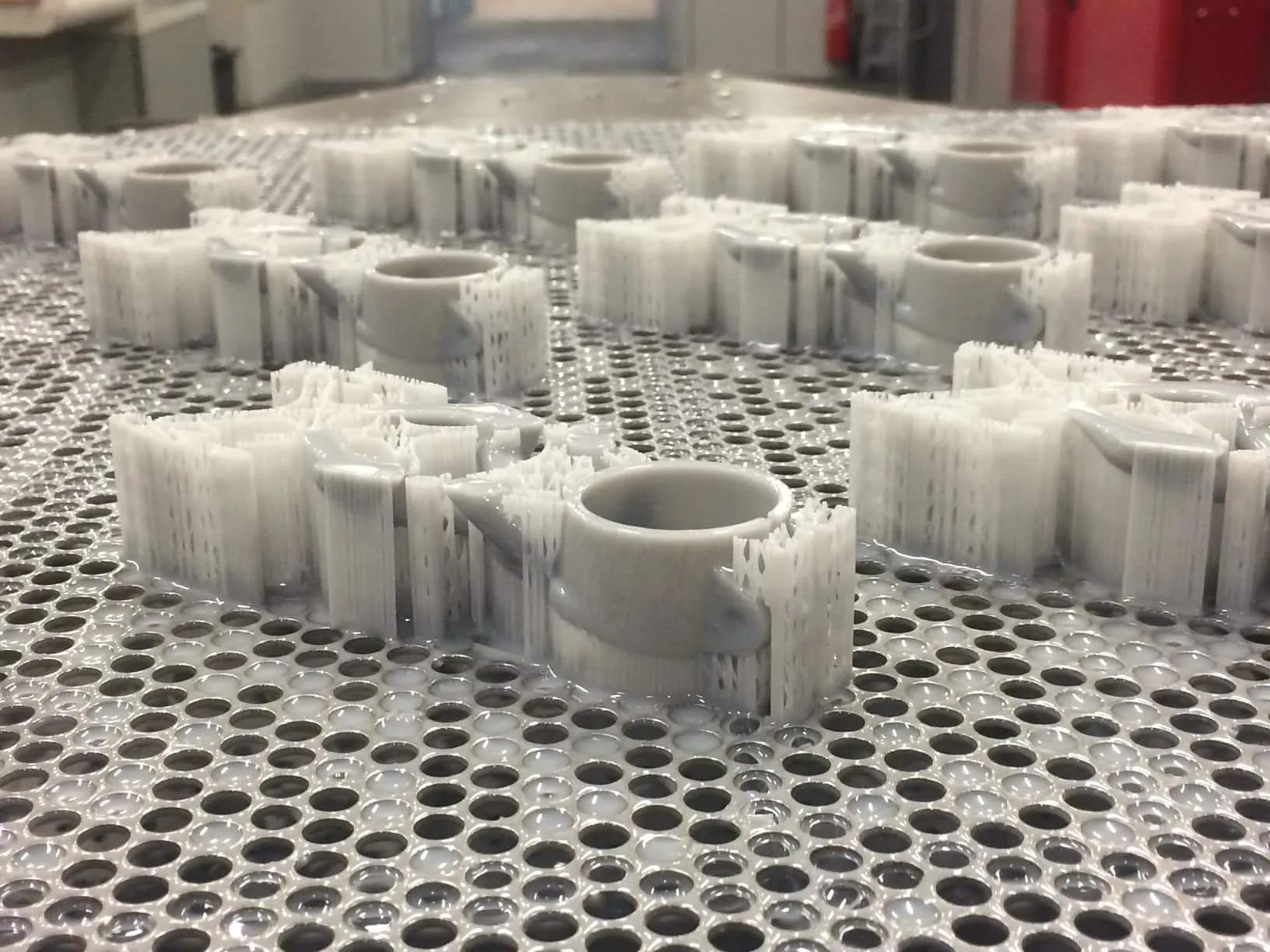

Composite materials for 3D printing processes

- Plastic Glass fiber

- Plastic Kevlar

- ABS Carbon fiber

- Gypsum

- PA Glass

- PA Aluminium

- PA Carbon fiber

- Plastic Carbon fiber

- PLA Wood

- PLA Copper

- Plastic Fibers

- Plastic Glass

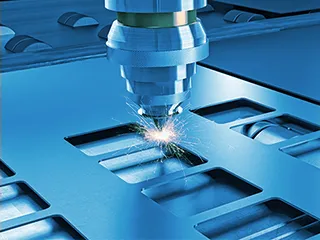

Composite materials for CNC machining processes

- PC Glass

- PA Glass

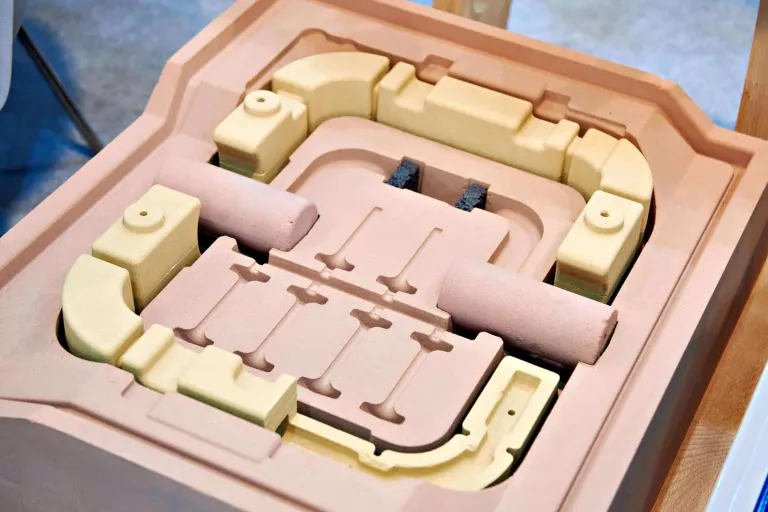

Composite materials for Cutting, Molding & Forming processes

- PA Glass

What are the composite manufacturing processes available at 3DEXPERIENCE Make?

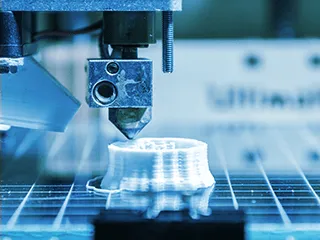

3D Printing - Additive manufacturing

FDM, SLS, MJF, BJ, SLA...

Cutting

Laser cutting, Water cutting, Blade

(Milling, turning & spark machining)

CNC Machining - Substractive

Milling, turning & spark machining

Forming

Sheet Metal, Extrusion, Forming, Stamping

Features to help you

Check & repair or Geometry check is a feature that helps you to understand Geometry issue of your part and could repair it live and online.

Check & Repair

Check & repair or Geometry check is a feature that helps you to detect geometry issue on your part and repair it online and live.

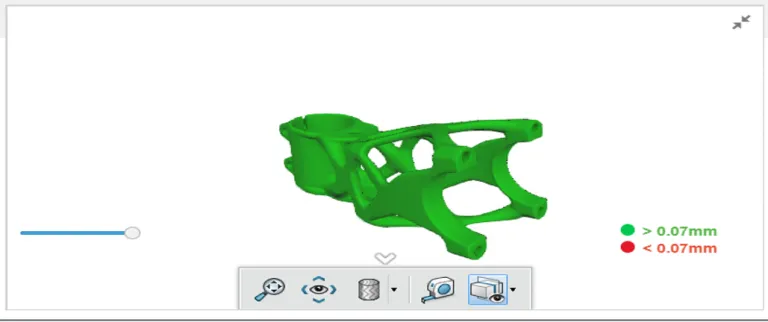

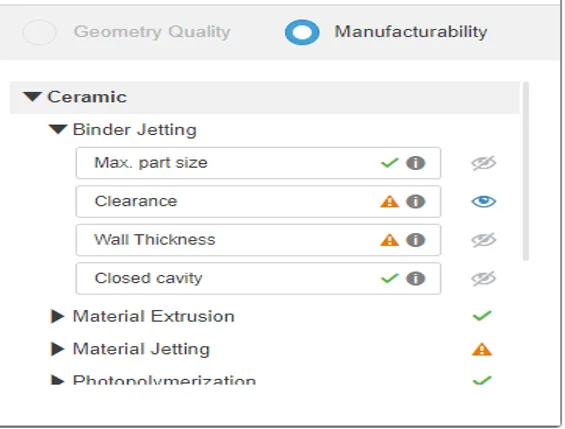

Manufacturability Check

This feature is available only for 3D Printing service. It helps you check the manufacturability of your part, depending on the materials and the process.

Instant quote engine

Receive in seconds several quotes thanks to our instant quote engine.

What is a composite?

Composites are made by bonding two or more materials with complementary strengths and weaknesses together. They typically include a binding substance called a ‘matrix’ and a ‘reinforcement’ material that, once combined, provides superior properties to each individual component.

Though many are human-made, there are numerous natural composites, such as wood, which combines cellulose fibers in a matrix of lignin.

Most composites are created from the mixing of wet materials which harden or set over time. A process that can take anything from hours to weeks.

The matrix and reinforcement can be easily seen in the final composite. This characteristic is what separates composites from chemical compounds, solutions and mixtures.

Combining different materials and volumes together changes the enhanced synergy between them, enabling scientists to precisely optimise a composite to solve a particular problem.

Despite their generally high cost, fiber-reinforced composite materials are increasingly being relied upon for high-performance applications due to their high strength-to-weight ratio. They can better withstand the stringent requirements and loading pressures faced by aerospace structures, boat and scull hulls, bicycle frames and racing car monocoques.

The Boeing 787 Dreamliner and the Airbus A350 both have airframes, fuselages, wings, rudders largely comprised of composites.

Composites also continue to replace wood and metal in a wide variety of sporting goods, including tennis racquets, baseball bats, golf clubs, hockey sticks, rowing paddles, fishing rods, and all manner of boards and supports.

Discover our other materials for manufacturing

Metal

Aluminium, Nickel, Stainless, Steel, Titanium, etc...

Plastic

ABS, POM(Acetal/Deltin), PEEK, PTFE, HDPE, PEI, PC, PP, etc...

Wax

Wax support, UV Curvable, etc...

Sand

Get multiple quotes for your parts in seconds