Five Industries that Benefit the Most from 3D Printing

3D printing benefits five industries the most. 3D technology is evolving quickly. Learn more now!

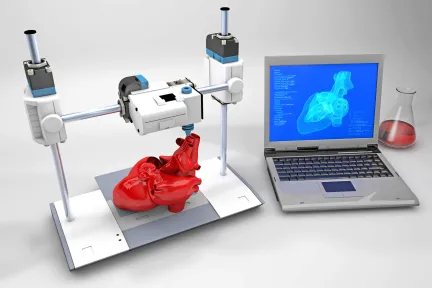

The growth of the 3D printing industry

The rapid growth of the 3D printing industry is due to the growing number of applications of this technology across industries, from printing custom dental implants to customized products to printed food to printed housing. The material list used in 3D printing is helping to propel the industry with a variety of plastics, polymers, metals, wood, ceramics, resins, wax, and food.

3D printing is still in its infancy, with groundbreaking strides and innovations. Many view 3D printing as the catalyst for the 4th Industrial Revolution, also known as “Industry 4.0.” The term Industry 4.0 is the inclusion of new technologies to revolutionize how industry manufactures, improves, and distributes products. These new technologies include automation, cloud computing, artificial intelligence, analytics, the Internet of Things (IoT), cyber-physical systems (CPS), and 3D printing throughout their operations.

Five Industries that Benefit the Most from 3D Printing

3D printing technology has spread across almost every sector of industry. New products and materials are being developed rapidly in an industry with practically unlimited potential. The latest forecasts predict that 3D printing, which was $4.4 billion in 2013, is expected to grow as much as 24.3% annually to $94 billion by 2030.

This article discusses 3D Printing and the five industries that benefit the most from the technology.

Aerospace

3D printing is revolutionizing the aerospace industry, enabling faster and more cost-effective production of parts and components. This technology has created spacecraft, aircraft, missiles, and more components. 3D printing makes fuel tanks, engine components, and other parts for aircraft. It also helps reduce production costs and speed up the manufacturing process.

3D printing allows aerospace engineers to design complex parts that would be impossible to manufacture using traditional methods, such as metal injection molding.

Furthermore, 3D printing offers greater design flexibility, allowing engineers to quickly create prototype parts that can be tested and modified without costly delays. 3D printing can also reduce material waste, allowing parts to be printed to exact specifications, and eliminating the need for excess material.

Finally, 3D printing can speed up the manufacturing process, allowing aerospace companies to produce parts faster and with less labor, which reduces costs and increases efficiency.

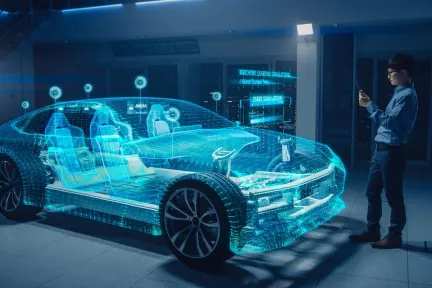

Automotive

3D printing is becoming increasingly popular in the automotive industry to quickly and cost-effectively produce complex parts and components. 3D printing has produced tooling, jigs, and fixtures for prototyping, testing, and production. It can also create lightweight parts for vehicle body panels, interiors, engines, and transmission components. The automotive industry is also looking at 3D printing to produce parts on demand, saving time and money in manufacturing. 3D printing is also being used to create custom parts for after-market customization.

3D printing creates automotive parts such as engines, chassis, and other components. It also enables manufacturers to develop prototypes and test new designs quickly.

Education

3D printing is becoming a popular tool in the educational sector. It is being used in a range of different ways to help students gain a better understanding of their chosen field. Educators are using 3D printing to create physical models and prototypes to help demonstrate concepts and theories more tangibly. It is also used to develop educational tools and materials, such as 3D-printed anatomical models and chemistry sets.

This technology allows architecture students to generate 3D models of their designs, engineering students can print out their prototypes, and chemistry students can print 3D sculptures of molecules. 3D printing has also been used to create robotics and coding projects in the classroom and is being used to create customized learning resources. 3D printing in education allows students to explore new ideas and concepts in a hands-on way, which can help foster creativity and collaboration in the classroom and better understand complex concepts.

Manufacturing

3D printing Industry in Manufacturing 3D printing technology is revolutionizing manufacturing, enabling companies to create parts and products with greater speed, accuracy, and efficiency than ever before. Traditional manufacturing processes that have been in place for decades are now being transformed. 3d Printing allows goods to be produced at an extraordinary speed, using fewer and fewer materials and reducing labor. 3D printing enables manufacturers to make parts and products with complex shapes and intricate details previously impossible to create with traditional methods.

In addition, 3D printing eliminates the need for costly tooling and other equipment and enables manufacturers to produce small batches of parts and products with minimal lead time and low overhead. 3D printing is also used in various industries, such as automotive, aerospace, medical, and consumer products, allowing companies to prototype designs rapidly and bring products to market faster than ever before.

Robotics

The 3D printing industry has become intertwined with robotics as a means of producing complex components and components for robots. 3D printing enables the production of intricate parts and components for robots with a high degree of accuracy and precision. This has allowed robotics companies to produce robots with more advanced features and capabilities than ever before. Industrial robots are incredibly complicated machines that are often used in harsh environments. 3D printing can be used to replace failed parts in a quick, cost-effective way.

The use of 3D printing technology in robotics has enabled the production of robots with greater agility, dexterity, and range of motion, as well as enhanced strength and precision. 3D printing has also been used in developing robotic prosthetics and exoskeletons, which can help people with disabilities to live more independently. In addition, 3D printing can be used to create customized parts and components for robots, including those used in medical and military applications. The 3D printing industry has only scratched the surface of its potential.

Learn more about industries and 3D Printing

Get multiple quotes for your parts in seconds