3D printing in the retail sector

3D printing has the potential to disrupt all aspects of retail thanks to its ability to deliver faster production times, more sustainable operations and mass customization.

What is 3D printing?

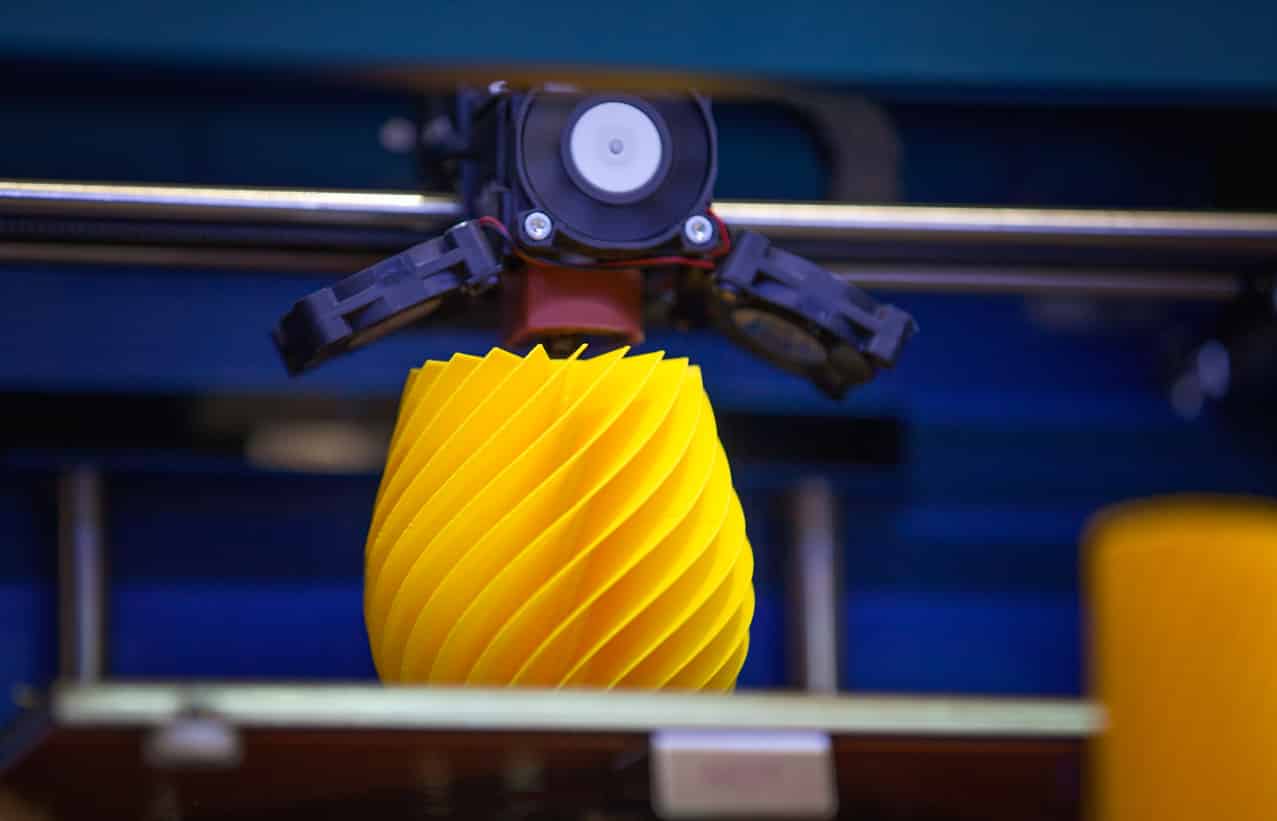

3D printing, or additive manufacturing, is a production technique that creates a three-dimensional object from a computer-aided design (CAD) file. The term covers several different processes that see one or more materials – typically plastic, metal, wax or composite – being deposited layer by layer to build a shape.

The entire process is computer controlled, making 3D printing a cost-effective, efficient and accurate method to create objects of almost any geometry or complexity. Today, 3D printing is used in every industry to produce prototypes, tools and jigs, components and end-use parts.

3D printers come in various sizes, from small enough to fit on a benchtop to large-format industrial machines.

Large printers can produce bigger objects, but the machines take up more space and cost significantly more than benchtop printers. Achieving a successful print is also more complex on a large-format machine due to the volume of material and printing time involved.

How is 3D printing transforming the retail sector?

3D printing in retail brings many advantages, including:

Accelerating the product design process

Greater design flexibility

Faster production and delivery times

Minimizing raw material and inventory wastage

Streamlining supply chain management

Mass customization at scale

Simplifying the sourcing of hard-to-find or unobtainable spare parts

The retail sector is one of the fastest-growing adopters of 3D printing. This is unsurprising given the many branches of retail and the rising number of use cases for the technology.

3D printing in retail provides a new level of design freedom. The technology can produce highly complex, unique forms that would be hard if not impossible to make any other way. This is a key advantage in markets where visual appeal, style and being unique greatly influence customer buying decisions.

Chief among the benefits of 3D printing in retail is the ability to cost-effectively and efficiently offer mass customization.

The modern consumer seeks a product individually tailored to their tastes and needs, delivered via a meaningful and memorable experience. They also prioritize convenience, personal interactions and sustainability and want greater control over the end-to-end process.

In response, brands must continuously evolve and reinvent themselves and their products to attract and retain ever-more demanding customers. This need perfectly aligns with the increasing maturity and capabilities of 3D printing technology, materials and techniques.

Some of the world’s most recognized brands such as Adidas, BMW MINI, Chanel, IKEA, Paperchase and Whirlpool are already using 3D printing. As are numerous start-ups and market disruptors.

Yet, the use of 3D printing in retail is far from mainstream. Currently, it is used to produce niche, novel and luxury items rather than high-volume consumer goods. This is beginning to change as 3D printing becomes more price competitive with traditional manufacturing methods. Additionally, the quality and detail of prints, known as resolution, continue to improve and brands and consumers are becoming more familiar with 3D printing in retail.

3D printing is helping provide a new running experience

What happens when you combine 17 years of athlete data, more than 5 million lattice variations and one of the world’s largest sportswear and shoe manufacturers? The result is a 3D printing innovation designed to move runners forward.

In 2017, Adidas released “the world’s first high performance footwear” featuring a 3D-printed lattice midsole. The unique lattice structure offers improved impact absorption, stability and material breathability.

Thanks to 3D printing, the process of making an individual midsole now takes 20 minutes rather than 90 minutes.

The sporting giant took the concept a step further in 2020 with the release of its Futurecraft STRUNG. The shoe features a 3D-printed midsole that combines performance data and robotics to precisely manufacture footwear modeled to the exact contours of each wearer’s foot.

More recently, Adidas released its latest generation of 3D-printed midsole called 4DFWD. Its most advanced shoe to date has all the benefits of previous iterations with a new and improved lattice midsole that can be finely tuned to provide a sock-like fit while letting the foot breathe freely.

The unique bowtie-shaped cell design of 4DFWD was selected from more than 5 million possible lattice structures and has been specifically arranged to compress forward upon vertical impact. As a result, the design generates up to three times more forward motion than previous generations of 3D-printed midsole.

According to Adidas, 3D printing technology provides the opportunity to design in a way that conventional foam midsoles simply do not allow.

How is 3D printing in retail used?

ON-DEMAND MANUFACTURING

Shoppers frequently go to buy something and it’s out of stock or not available in the right size, color or style. Added frustration is caused by ordering it and waiting weeks or even months for it to arrive. This undoubtedly results in consumers settling for something good enough but not perfect.

On-demand manufacturing with 3D printing means items can be viewed, modified and chosen using an app and then collected or delivered direct. The entire process is done in a matter of days, sometimes hours.

The opportunities are endless. Examples already span sports equipment, beauty products, souvenirs, stationery, children’s toys and cake decorations.

But it’s not just customers who benefit. 3D printing in retail enables companies to operate more efficiently and profitably and centralize manufacturing. It also helps overcome one of the trickiest parts of retail – predicting demand.

Long lead times (the amount of time between ordering something and receiving it) mean retailers must accurately forecast what customers will want and need months in advance. Order too little and the resulting supply shortage sees customers going elsewhere. Too much and the unsold stock must be stored, sold at a discount or disposed of. All of which cost money.

Compare that to 3D printing where products are made when needed and only in the quantities required. No minimum order requirements or money tied up in unsold stock, no warehouses or time-consuming stocktaking, and manufacturing can take much closer to where the demand is, even in-store.

MASS CUSTOMIZATION

One of the most exciting advantages of 3D printing in retail is the cost of making one item is the same as thousands, regardless of how complex it is. This allows consumers to truly make a product their own and shifts the emphasis from seller-designed to user-designed.

The ready-accessibility of 3D printing with high-definition digital scanning technologies takes personalization to even greater heights. Products such as ear headphones, jewelry and shoe insoles can now perfectly match a user’s unique anatomy without the need for manual measurements and mold-making. This greatly increases the accuracy, efficiency and affordability of the process.

PRODUCT DEVELOPMENT

3D printing in retail means products can be brought to market more quickly and affordably, with much lower risk. Being able to produce a small number of products provides the flexibility to test innovations without investing in large-scale manufacturing processes, tooling and supply chains.

Market feedback can be quickly gathered and integrated into the next potentially larger batch of products. This helps consumers feel more connected to the process and provides valuable insights to the retailer.

Prototyping is also an important part of the design process. Prototypes are early-stage concept models that show how a product truly looks, feels and functions. They are often used by retailers in trade show environments or in-store.

3D printing in retail is often used for rapid prototyping – using the technology’s speed and efficiency to produce design iterations in a fraction of the time versus traditional, more manual techniques. This allows more testing to be done in the same or shorter period and helps to highlight potential issues or improvements earlier.

SPARE AND REPLACEMENT PARTS

Ensuring the availability of spare parts across an almost infinite number of products is a challenge for retailers. Providing the right part in the right location with minimal delay leads to retailers stockpiling large quantities or waiting until demand is high enough to justify manufacturing a small batch. Either option is costly and can mean a long delay for customers with products awaiting repair.

The cost of fitting a replacement part is often higher than a total replacement. It may be impossible to source a part for something no longer in production. 3D printing in retail enables spare parts to be made quickly and cost-effectively, when and where needed. This helps optimize stock levels, eliminates the need to maintain storage facilities and avoids a huge number of repairable products unnecessarily going to landfill.

PACKAGING AND DISPLAYS

3D printing in retail is also being used to produce eye-catching and unique window displays and packaging.

L’Oréal, for example, is one of several cosmetic brands using 3D printing to create packaging that combines technology with craftsmanship. The limited Haute Couture edition of its Flowerbomb perfume has the glass bottle encased in a delicate cage of brambles and the flowers that mirror the scent.

Each element of the complex bouquet is 3D printed and then polished and assembled by hand before being immersed in a bath of rose gold metallic ink.

According to L’Oréal, “3D printing is pushing back the bounds of craftsmanship to create high-precision parts of such finesse and complexity that they are difficult for human hands to produce.”

PRINT-AT-HOME PRODUCTS

3D printers are more affordable and reliable than ever and are now routinely used for personal, professional and educational reasons. Though not as capable or versatile as industrial printers, consumer-level machines provide an exciting new level of convenience.

A rapidly growing list of digital design files can now be purchased and printed at home. The price of a file is often less than a finished product and can be easily customized to the end-user. The process is also more environmentally friendly as there is no transportation involved.

Though many view printing at home as a significant opportunity, there are concerns about the increased risk of counterfeiting and the impact it will have on a brand’s intellectual property.

Is 3D printing the future of fashion?

Fashion is one of the most talked about applications for 3D printing in retail. Designers have spent years experimenting with the technology to create unique and innovative garments, shoes, jewelry and accessories. Their complex creations grace red carpets and fashion show runways but not yet high streets.

The attraction of 3D printed fashion is three-fold: the opportunity to perfectly tailor an item to the individual wearer, ensuring each design is unique and designing freely without the constraints of traditional garment making.

However, clothing is among the hardest things to 3D print because it needs to be flexible and move in the right way. It’s more straightforward to 3D print items which don’t need to be so flexible such as handbags, jewelry and eyewear.

Making 3D printing clothing from rigid plastic materials has led most designers to use lattice-like structures which are individually printed and assembled. The time and complexity involved places 3D printed fashion firmly in the premium end of the clothing market.

3D printed fashion won’t enter the mass market until the volumes produced increase significantly, the costs involved come down and consumers become more exposed and familiar with the concept.

What are the limitations of 3D printing in retail?

3D printing in retail represents a game-changer with almost limitless growth opportunities. Yet the technology does have its limitations. This is especially true when it comes to delivering on its promise of mass customization.

LARGE SCALE PRODUCTION

In many cases, 3D printing in retail can produce a single item or small batch of items faster and more efficiently than conventional manufacturing methods. However, the technology still struggles when it comes to larger volumes.

Each machine can only print a certain number of objects at any one time, depending on machine size and object, so may not be the quickest or most cost-effective technique for many products that could benefit from mass customization.

INCONSISTENT QUALITY

3D printers can’t yet print perfect results every time. Failure rates depend on the machine and material used and the object printed. Also, removing surface irregularities or textures may require additional manual processing steps to achieve the desired finish.

Factors like failure rates and post-processing will likely reduce as the technology improves and people become more familiar with using 3D printing.

For objects based on a scanned model, the quality of the finished print will also be determined by how sophisticated the scanning equipment is. Higher quality prints may require investing in a more expensive scanner and 3D printer.

LIMITED MATERIAL CHOICE

For the most part, 3D printing in retail is limited to objects made from plastic and resin. Metals, high-grade composites and other such durable materials are still the preserve of industrial production processes.

LACK OF FAMILIARITY

Though growing in prevalence, 3D printing in retail is not yet a mainstream fixture – certainly outside of prototyping and limited-edition luxury products. That time may come, possibly sooner than expected, but for now, the technology remains secondary to more conventional production methods.

3D printing is helping to make obsolescence obsolete

Electronic waste is the world’s fastest-growing waste stream. More than 50 million metric tons of e-waste were generated in 2021. Household appliances such as fridges, freezers and washing machines account for around half of all e-waste.

Many of these appliances could have been repaired rather than replaced and disposed of. The problem is often as minor as a broken dial, button or similar component. However, it’s not always easy, affordable or convenient to source and fit these replacement parts.

Increased emphasis on reducing the world’s carbon footprint has led to a global ‘Right to Repair’ movement. Some countries have already passed related legislation, with many more expected to follow suit shortly. Whirlpool is one of a growing number of companies to have introduced their own such initiative.

Whirlpool is one of the world’s leading global manufacturers of home appliances. It has almost 20 brands in its portfolio and more than 50 manufacturing and technology research centers around the globe.

The company has joined forces with Singapore-based start-up Spare Parts 3D to tackle obsolescence by making spare parts on demand.

An initial pilot project of 150 parts led to a review of Whirlpool’s entire parts catalog of around 11,000 items. Each one was individually assessed to determine which would be the most suitable and profitable for 3D printing. The assessment showed that 3D printing could be a more economical manufacturing method for 7% of components.

The first 3D printed part, a push button printed in Nylon using Multi Jet Fusion (MJF) technology, paves the way for a new way of thinking about spare part management.

According to a Whirlpool spokesperson, 3D printing in retail can have a direct impact on Whirlpool’s customer care by helping solve obsolescence and shortage issues.

While the number of 3D-printed parts is currently limited, the partners expect to deepen their collaboration and scale up the production in the coming months.

Get multiple quotes for your parts in seconds