Bearing Modules

Simpack Simulates Bearings Interaction with the Complete System

Simulate Bearings with Simpack

Bearings are the most frequently used machine element in power transmission. A poorly designed rolling bearing can quickly lead to damage of the bearing itself and the drive train. In the worst case, a chain reaction induces the total loss of your complete system. Simpack Bearing Modules enable the modeling of various types of rolling bearings such as ball, cylinder and barrel bearings and also also journal bearings and elastohydrodynamic bearings.

Journal Bearing

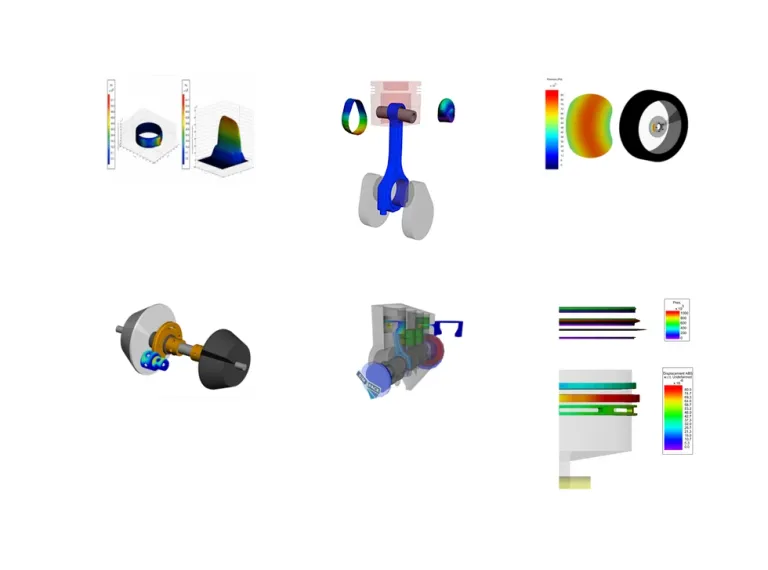

Journal Bearing is a Force Element used to model radial or axial journal bearings using a nonlinear stiffness and damping law. This Force Element can model any kind of radial or axial bearing where a force law acting on only two Markers would be unsatisfactory. Simpack Journal Bearing acts between several Markers on the shell and one center Marker on the shaft. A 3D effect can be achieved by adding several Force Elements in a row.

Elastohydrodynamic Bearing

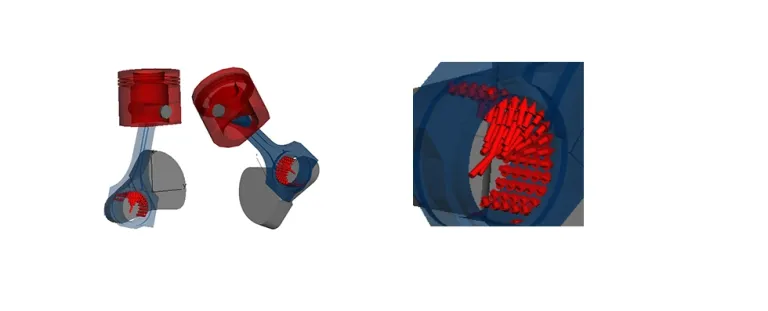

This Force Element can simulate hydrodynamic bearings by solving the Reynolds equation accurately and efficiently. The element includes rigid body hydrodynamics (HD), one-sided elastohydrodynamics (EHF) and double-sided elastohydrodynamics (DEHD). It allows the consideration of global temperature effects (TEHD) in the bearing and the surrounding solids. Special design parameters allow for easy and user-friendly consideration of oil bores, grooves ... Any level of detail can be simulated. The element can also simulate piston ring dynamics.

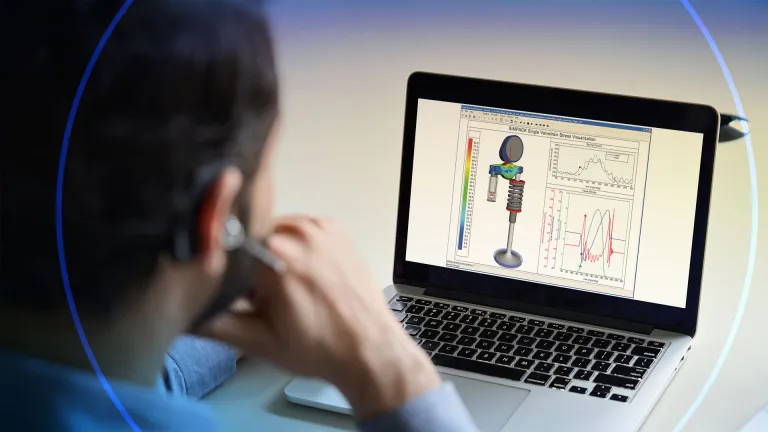

BEARINX®

Simpack BEARINX Map for Rolling Bearings enables the use of the BEARINX® software from Schaeffler Technologies in Simpack. BEARINX® allows the calculation of accurate bearing forces and torques for many rolling bearings.

Non-linear stiffness, coupling effects and bearing clearance are described by a characteristic field in a BEARINX Map (.bxm) file, which Schaeffler Technologies has to provide.

Simpack Rolling Bearings

Obstacles in Rolling Bearing Design and Selection

Bearings are the most frequently used machine element in power transmission. A poorly designed rolling bearing can quickly lead to damage of the bearing itself and the drive train. In the worst case, a chain reaction induces the total loss of your complete system. Detailed basic research works (for example PALMGREN, LUNDBERG, GAERTNER, see [1], [3] and [4]), introduced standardized formulas. These formulas enable engineers to properly design and select bearings in terms of carrying capacity by means of the bearings load spectrum. To calculate a reliable lifetime expectancy, the load spectrum must be as realistic as possible. However, due to unknown operational loads and complex interactions between the bearing and the system, the required representational bearing loads are hard to estimate. In addition, the demand on decreasing acoustic emission and detailed transfer path analysis is growing, which raises questions regarding the detailed rolling bearing dynamics and its influence on the system dynamics. To cover all these highly involved design topics confronting engineers required powerful tools for the dynamic roller bearing and system analysis.

Simpack Rolling Bearing Elements

To address the mentioned obstacles in Rolling Bearing analysis, Simpack offers the Force Element “Rolling Bearing”. This Force Element efficiently simulates all common types of rolling bearings by resolving the rolling element contacts under consideration of the inner geometry. On one hand, this approach takes the detailed transmitting behavior of a bearing into account, because it considers the non-linear stiffness characteristics, clearance and cross-coupling. The approach also covers the excitations generated by the bearing (for example due to rolling elements passing through the loaded zone). The high efficiency of this Force Element and the consideration of the transmitting and excitation effects of a bearing enable the engineer to generate realistic load spectra, which take the interaction of the rolling bearing with the complete system into account. In terms of carrying capacity, lightweight construction, and acoustic emission, this element makes the design and selection of the best bearing solution easier.

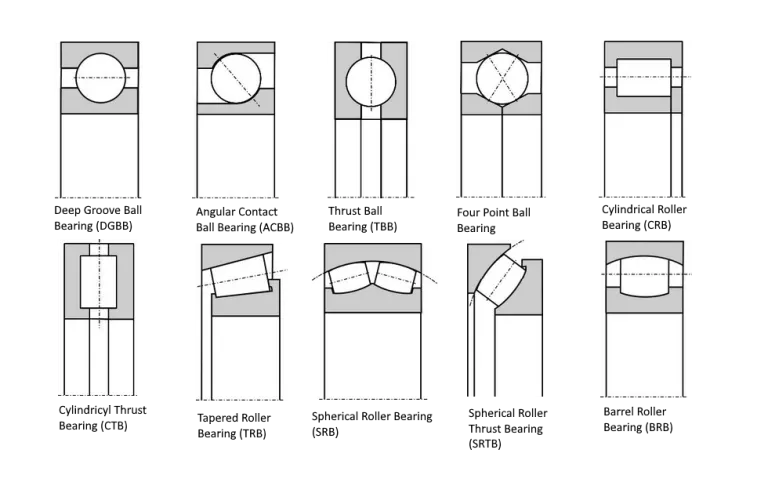

Supported Bearing Types

- Ball Bearings: deep groove, angular, thrust, four-point

- Cylinder / Needle: radial, thrust

- Tapered Roller Bearing

- Barrel and Spherical Roller Bearings

Key Features of Rolling Bearing

- Local contact evaluation considering inner geometry: Non-linear stiffness, cross-coupling, clearance

- Complete customization possible (pitch diameter, number of rolling elements, rolling element diameter, groove radii, roller profile, taper angle, …)

- Modeling per row concept: Design as many bearing rows as you want

- User-defined friction: Load-dependent and load-independent friction portions, speed-dependent friction coefficient

- Local contact damping

- Minimize the risk of an overdamped rolling bearing setup

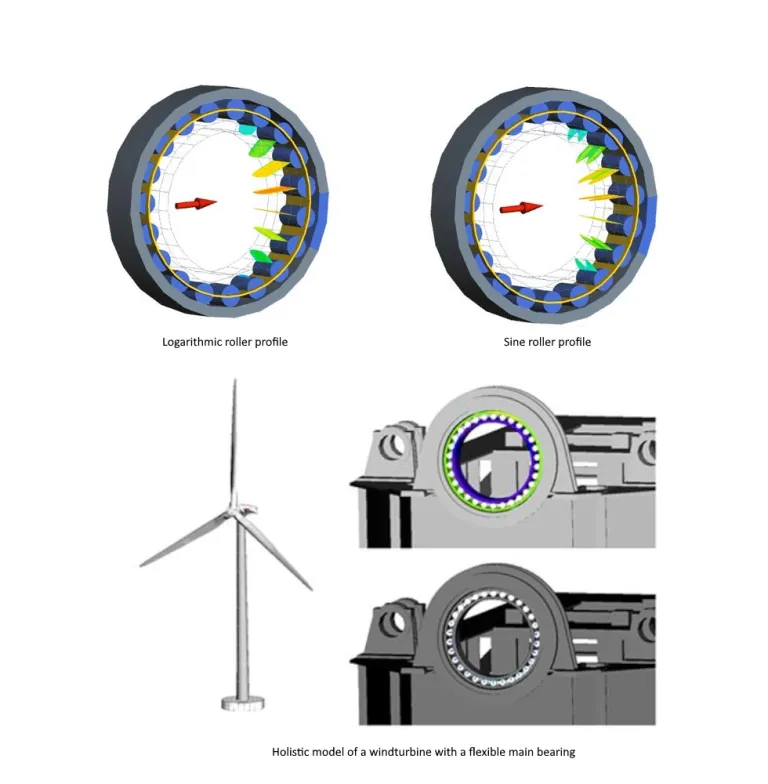

- Flexible bearings, even for multi-row bearings

- Real-time capability (Convince yourself, test the example models provided within the Simpack documentation)

- The high performance of the force element enables holistic simulations

Analysis and Outputs of Rolling Bearing

- Fast, robust and accurate simulation of roller bearings as a stand-alone model or as part of a complete system

- Overall radial, axial and tilting loads

- Radial and axial loads per rolling element

- Deflection of the complete bearing and of single rollers

- Contact pressure

- Load distribution (for example to calculate the modified reference rating life according to ISO16281 [4])

- Power loss and friction torque

- General flexible body outputs provided by Simpack (see Flexible Body Simulation Modules)

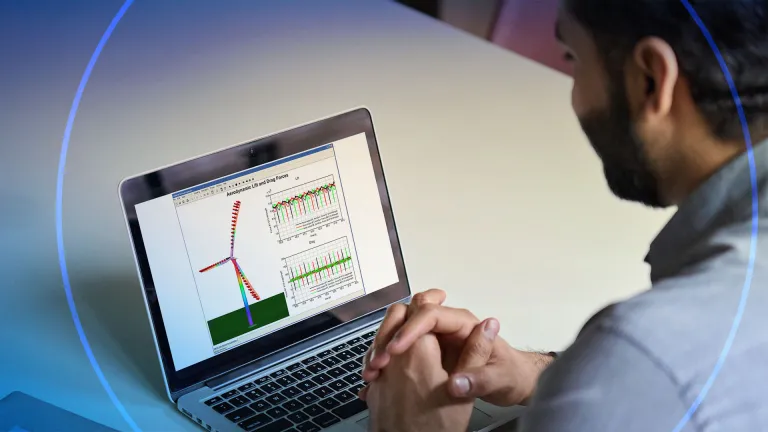

Example for a stand-alone and holistic bearing simulation

Analyze load distribution with variant roller profiles:

References:

[1] Gaertner: Ueber die Lebensdauer von Kugellagern, Dinglers Polytechnisches Journal, 1918

[2] Palmgren, A.: Ball and roller bearing engineering. 2nd Edition. S.H. Burband & Co., Inc., Philadelphia, 1945.

[3] ISO 16281: Rolling bearings — Methods for calculating the modified reference rating life for universally loaded bearings. ISO 16281, Technical Specification. June 2018

[4] Schlecht, B.: Maschinenelemente 2: Getriebe, Verzahnungen, Lagerungen. München: Pearson Studium, 2010.

Also Discover

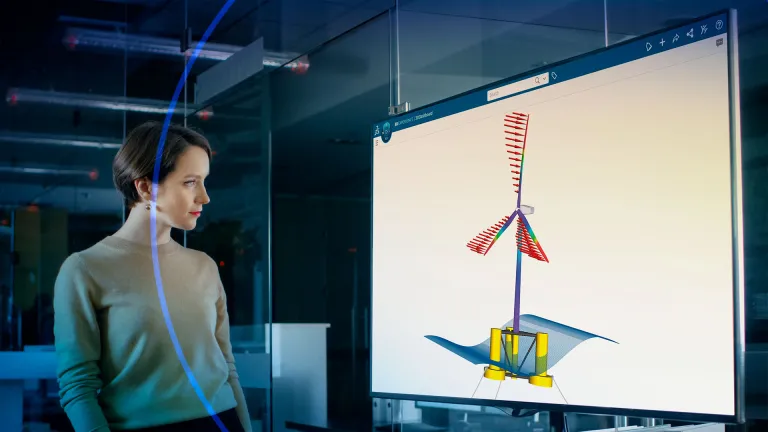

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering