Clear, Translucent, and Transparent Plastic 3D Printing

Discover Transparent Plastic 3D Printing and its applications in the industry.

Introduction Transparent Plastic 3D Printing

Clear, translucent, and transparent 3D printed parts are useful for a wide array of applications. These parts with varying degrees of clarity are predominantly printed for one or more of the following purposes: visibility to see what is inside of them, the ability to allow light to pass through them, and aesthetic reasons.

Difference Between Clear, Translucent, and Transparent Materials

The ability to see through a clear plastic 3D printed part depends on the material utilized. The difference between plastic parts with transparency or clarity classifications such as clear, translucent, or transparent is key to understand, before specifying 3D printing materials or selecting printing processes. It is also important to understand how refraction, specular reflection, diffuse reflection, and absorption alter the transparency of an object.

- Specular reflection (AKA reflection) happens when almost all the light rays that hit a surface bounce off the surface in a single direction i.e., mirrors.

- Diffuse reflection happens when almost all the light rays that hit a surface bounce off in a multitude of directions i.e., non-glossy painted surfaces.

- Absorption refers to a phenomenon whereby nearly all the light that hits a surface is absorbed by the material itself i.e., black chalkboards.

- Refraction occurs when light is transmitted through a material i.e., glass or water.

Transparent objects tend to refract light or allow light to predominantly pass through them, instead of the light bouncing off the surface. Light travels through different materials at different speeds. The speed at which it travels through a material, or the index of refraction, is an indicator of the transparency of the material. More specifically, the index of refraction is the ratio of the speed of light in a vacuum to the speed of light in a medium. As is evident from the data in the following table, the higher the index of refraction, the less transparent a material is:

- Air: 1.0003

- Polycarbonate: 1.052

- Water: 1.33

- Polylactic Acid (PLA): 1.450

- Acrylic: 1.489

- Polyethylene Terephthalate (PET): 1.549

- Quartz: 1.533-1.544

- Rock Salt: 1.544

- Aluminum: 1.667

- Diamond: 2.417

From the above table, one may discern that some common 3D printing materials are not optimal if the desire is to perform clear 3D printing, due to their relatively higher refractive indexes.

Clear 3D Printed Parts

A clear 3D printed is tinted to a certain color, so it is not fully transparent. Clear 3D printed parts are relatively see-through, but they are typically not polished to a finish that allows all light to pass entirely through them. It will typically have a higher index of refraction than non-tinted a 3D printed translucent or transparent part. Post-processing methods such as spray coating, polishing, and resin dipping can help to achieve a higher level of transparency in clear 3D printed parts. Sometimes, as is done in this article, clear 3D printed parts are used to refer to color tinted or non-tinted.

Translucent 3D Printed Parts

Translucent 3D printed parts are relatively clear, meaning some light will pass through them. Translucent 3D printing, or translucid 3D printing results in a light pattern through the material with a significant amount of diffusion or distortion. More specifically, if a printed paper with text on it is placed on one side of a translucent 3D printed part and read from the other side of the part, the text will not be legible because it will be fuzzy or unclear. This is because the light changes direction many times within the material, some reflecting and some refracting. Because of this, translucent materials have a relatively higher index of refraction. Examples of translucent materials include tinted car windows, wax paper, vegetable oil, stained glass, and frosted shower glass doors.

Transparent 3D Printed Parts

Transparent 3D printed parts have a high level of light passing through them, via the phenomenon known as refraction. Henceforth, transparent materials typically have a low index of refraction (the light passes through them at a similar speed as the light goes through a vacuum). It is also important to note that some materials with a higher index of refraction may also have low reflectivity, resulting in a higher level of transparency than other materials with the same index of refraction. Typically, materials with a higher index of refraction have a higher degree of reflectivity and a lower percentage of transparency. The following equation provides a calculation for the percentage transparency versus the refractive index:

Where: T=percentage transparency

N=index of refraction

NOTE: for reference, the value in the brackets is the reflectivity

Most of the light going through doesn’t bounce around in different directions in a transparent material, meaning that text placed on one side of a 3D printed transparent part is legible from the other side of the part. Transparent materials are all around us; examples include air and glass.

Can You 3D Print Clear Plastic Parts?

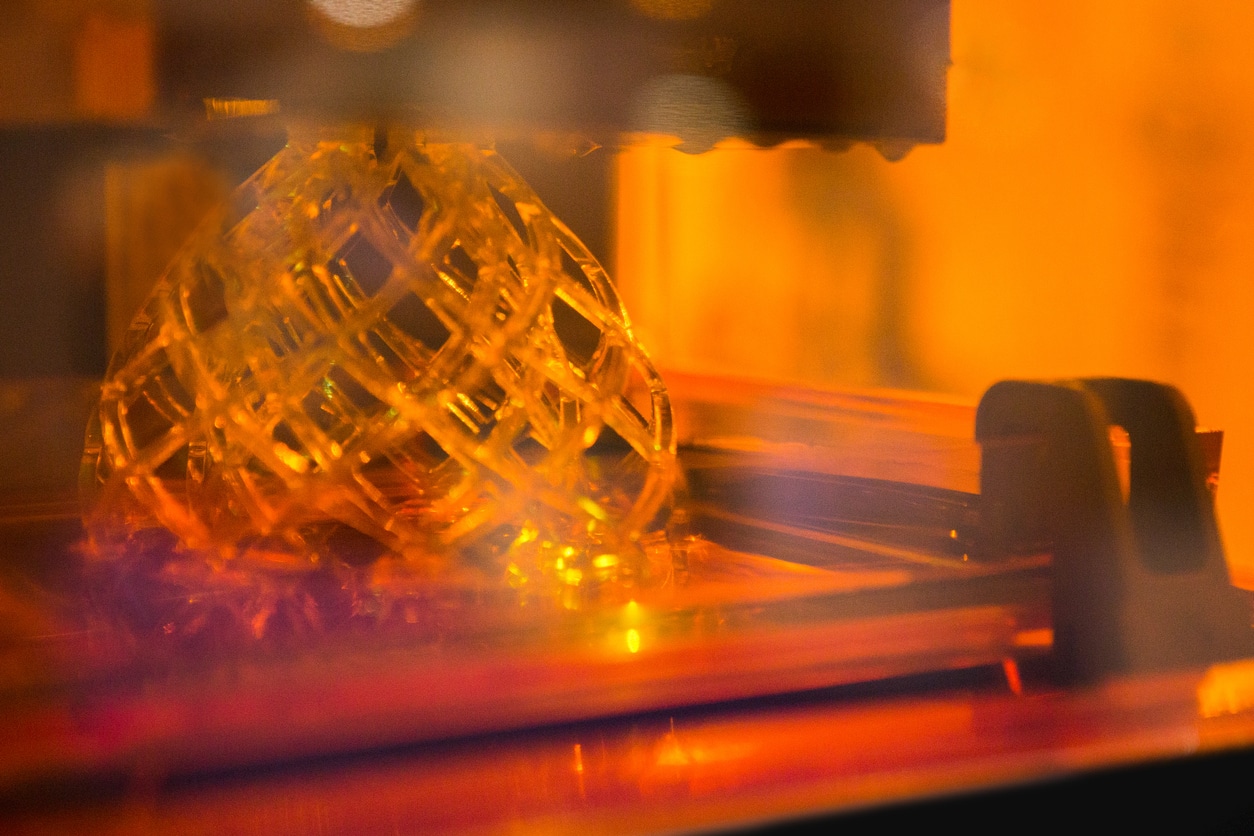

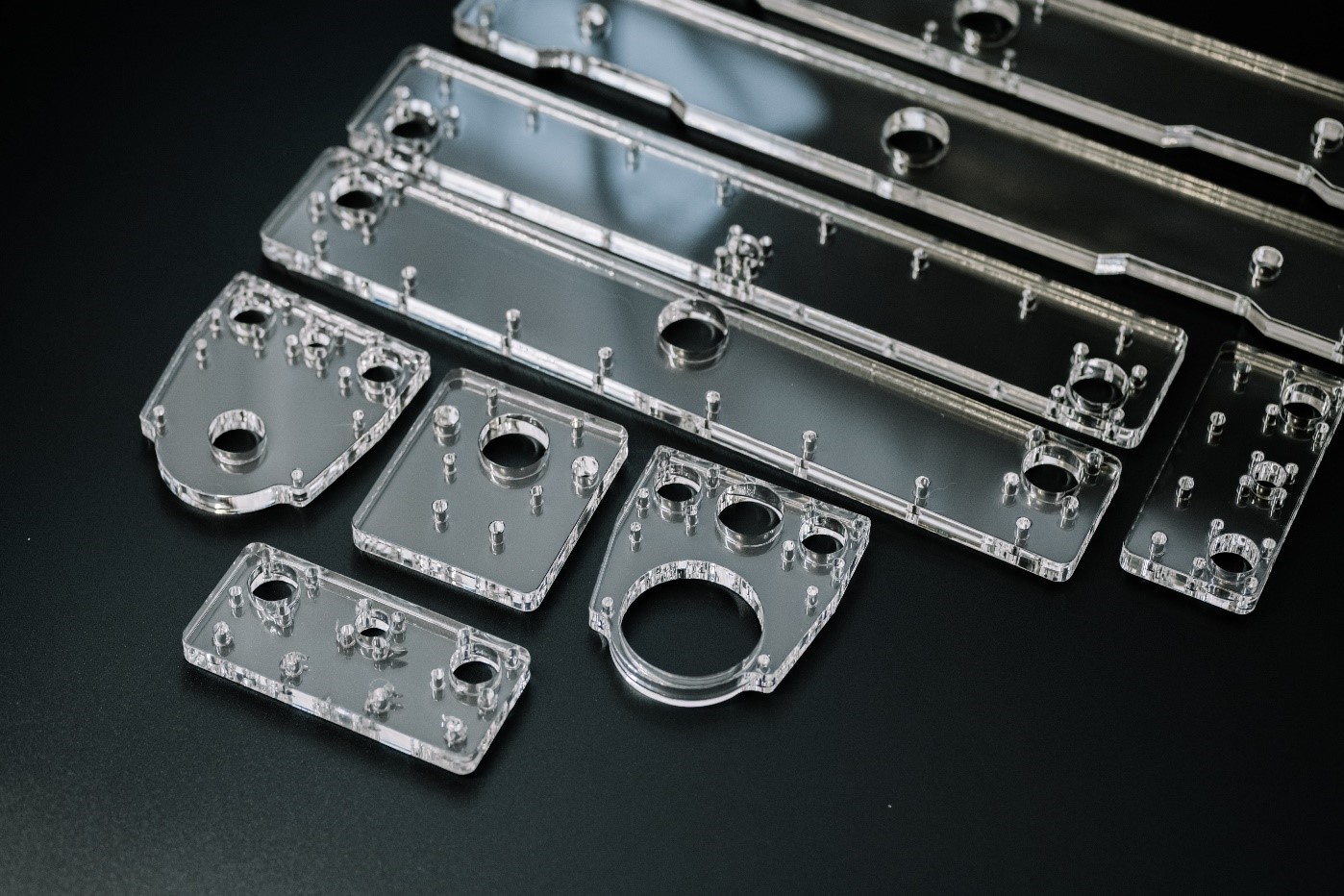

Yes, clear, or transparent plastic parts can be 3D printed. The optimal method for 3D printed clear or transparent plastic parts is stereolithography, or SLA, 3D printing. Filament-based 3D printing may not yield the desired level of transparency due to the small gap formed between the layers of material. This results in light bouncing around within the part, reducing the index of refraction, and increasing reflectivity. Polyjet 3D printing is another great method for 3D printing clear or transparent parts. This method of 3D printing allows for the utilization of materials such as UV curable resins and produces smooth parts.

Here are a few helpful tips to printing clearer or more transparent 3D printed parts:

- Utilize a flexible resin tank to reduce peel forces

- Aim to print 3D clear plastic parts with a smooth surface finish

- Utilize post-processing steps to further improve the transparency of the 3D printed parts

- Research and/or test different printer settings such as extrusion temperature, print bed temperature, layer thickness, extrusion nozzle diameter, printing speed, and flow rate.

Post-3D print processes may improve the transparency of a clear 3D printed part. Sanding and polishing simple 3D printed clear parts can be utilized to improve the reflectivity of the surface and smooth out blemishes. A mineral oil application can be utilized to create a semi-transparent, smooth finish and hide any light spots on a clear 3D printed part. Clear coating with or without prior sanding produces parts that are more transparent as well. For example, this method is utilized for bottles and packaging. Clear coating ranges from simple off-the-shelf options, such as those manufactured by Rustoleum, to more expensive and complex sprays, such as acrylic urethane. Resin coating is an excellent post-processing method for achieving very transparent 3D printed parts. Resin coating produces a smooth, clear surface with sharp surface reflections. It may reduce detail but provides a supremely smooth surface.

Dassault Systèmes provides a simple way to have your clear 3D printed parts expertly produced. Check out our website today to learn more about our innovative 3DEXPERIENCE® Make with on-demand access to industrial clear 3D printed parts service providers.

Applications of Clear 3D Printed Parts

Clear, transparent, or translucent 3D printed parts have a wide variety of applications. One of the most innovative applications is for printing prototype parts. For prototype parts that are part of a moving assembly, the transparency allows testers or design engineers to see through the parts and observe the interaction amongst the components in the assembly. Components that are utilized to distribute or transmit light for optical applications are also good applications for clear or transparent 3D printing. Examples of relevant optical components include LED housings, light pipes and decorative LED light covers. Clear 3D printed parts are also popular in the electronics industry for covers, viewing windows, or caps. Consumer products often involve the use of clear 3D printed parts for doors, decorative components, or viewing windows as well. Lastly, the popular utilization of clear 3D printing is for decorative or artistic renderings. 3D printing clear or transparent parts allows artists to create unique pieces where they can utilize the pattern of light that travels through the material to add an extra layer of visual depth to the piece of art.

Get multiple quotes for your parts in seconds