SLA 3D Printing Materials Compared

SLA 3D printing materials are amazingly versatile and can be used in various applications because of their many advantages.

Introduction to SLA 3D Printing Materials Compared

Stereolithography (SLA) 3D printing is known for its ability to offer highly accurate plastic parts with intricate features and smooth surface finishes. SLA materials include a wide variety of resins that have great utility in many different types of applications:

- Standard resins are excellent for rapid prototyping

- Engineering resins offer superior thermal and mechanical properties

- Medical and dental resins have biocompatibility certifications

- Castable resins don’t leave behind reside after burnout

In this article, we discuss the most common SLA materials, as well as their applications and advantages. Before diving in, let’s consider a brief overview of these fantastic materials.

Overview of SLA Materials for 3D Printing

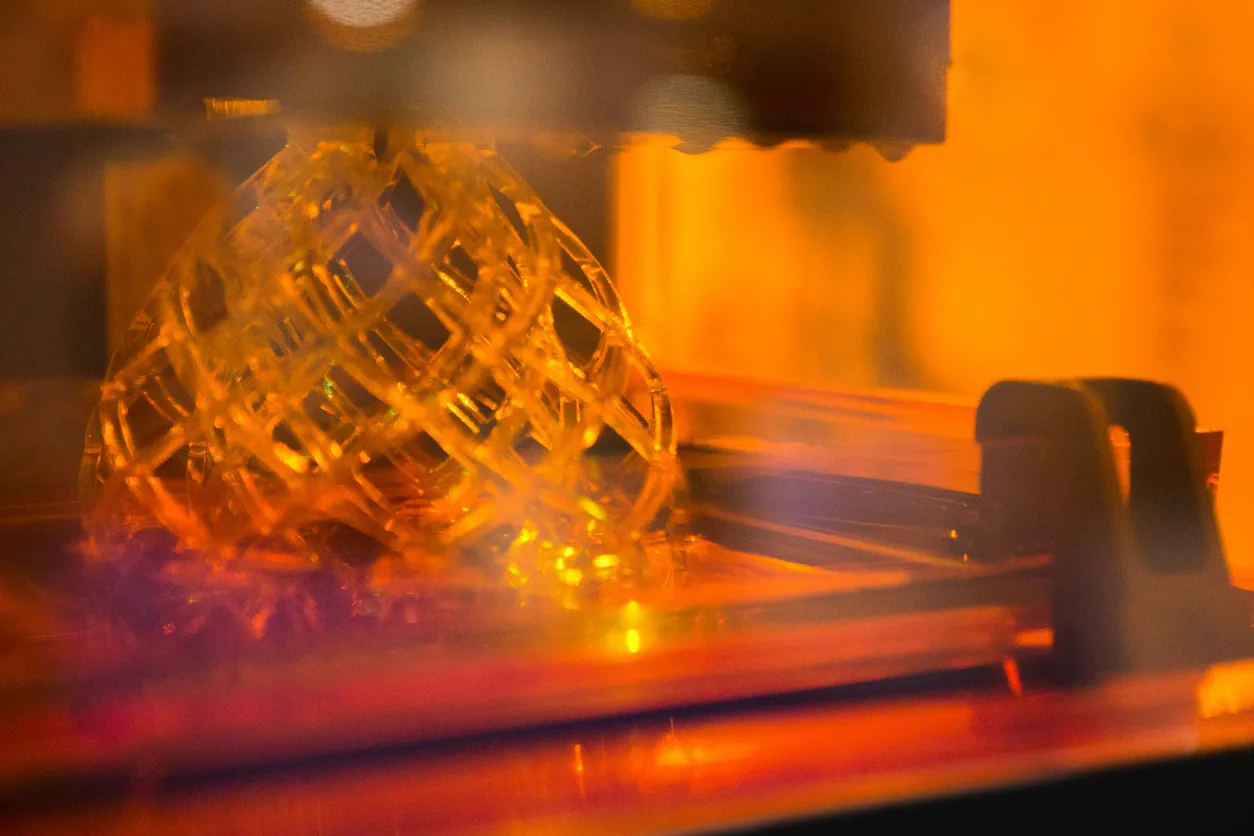

SLA 3D printing is a photopolymerization process that uses a UV laser to cure liquid resin into hardened plastic. The liquid resins utilized in SLA 3D printing include various blends of monomers, oligomers, photoinitiators, and other additives that result in different material properties based on the intended application of a given part or prototype. SLA resins provide smooth surface finishes, lots of rigidity, and the ability to create intricate details. Let’s take a closer look at the most common types of SLA 3D printing materials and their applications.

Common SLA 3D Printing Materials and Their Applications

Standard SLA Resins

-

Standard Resin. Standard resin offers rigid, high-resolution prints with a smooth surface finish. Standard resin is very affordable, which makes it an excellent option for rapid prototyping applications. One exciting aspect of standard SLA resin is that its color has some degree of bearing over its properties. For example, white resin is great for parts that demand a smooth surface finish, whereas gray resin is best for parts with intricate features.

- Clear Resin. Clear resin has the ability to be near transparent after post-processing. Clear resin has similar mechanical properties to standard resin, which means it’s great for rapid prototypes with intricate details. Additionally, clear resin offers smooth surface finishes. Clear resin is commonly used in applications such as fluidic devices and LED housings.

Engineering SLA Resins

Engineering resins can produce parts and prototypes similar to injection-molded plastic parts. It’s important to note that all engineering resins must undergo post-curing under UV light in order to obtain optimal mechanical properties.

- Tough Resin. Tough resin is intended for applications that involve high degrees of stress and applied force. In this respect, tough resins are similar to ABS. In fact, parts that are SLA printed with tough resin have tensile strength of 55.7 MPa and a modulus of elasticity of 2.7 GPa—both of which are similar to ABS material. Moreover, tough resins are shatter-resistant, which makes them great for applications such as rugged prototypes or enclosures with snap-fit joints.

- Durable Resin. As the name implies, durable resin is extremely resistant to wear and tear. It’s also very flexible, which makes its properties similar to that of polypropylene (PP). Additionally, durable resins offer very smooth surface finishes, which makes them a great option for rapid prototyping consumer products, low-friction moving parts, and ball joints.

- Heat Resistant Resin. Heat-resistant resins are excellent candidates for SLA 3D printing applications that demand high thermal stability and the toleration of high temperatures. Specifically, heat-resistant resins provide a heat deflection temperatures between 200–300°C. This property makes them excellent options for mold prototypes, hot fluid flow equipment, heat-resistant fixtures, and casting and thermoforming tooling.

- Flexible Resin. Flexible resin enables product and part engineers to mimic rubber parts. As such, flexible resin offers high elongation at break and a low tensile modulus. These properties make this resin an excellent candidate for parts that will be compressed or bent. Moreover, flexible resins are great for ergonomic add-ons to applications such as stamps, packaging, handles, wearable prototyping, grips, and overmolds.

- Rigid Ceramic-Filled Resin. These resins are reinforced with ceramic particles such as glass, which produces a high degree of rigidity and smooth surfaces in the prints. Plus, rigid resins offer thermal stability and heat resistance. Moreover, these resins offer resistance to deformation over time. These properties make rigid ceramic-filled resins great for applications such as jigs, molds and tooling, fixtures, manifolds, and housings for automotive and electrical components.

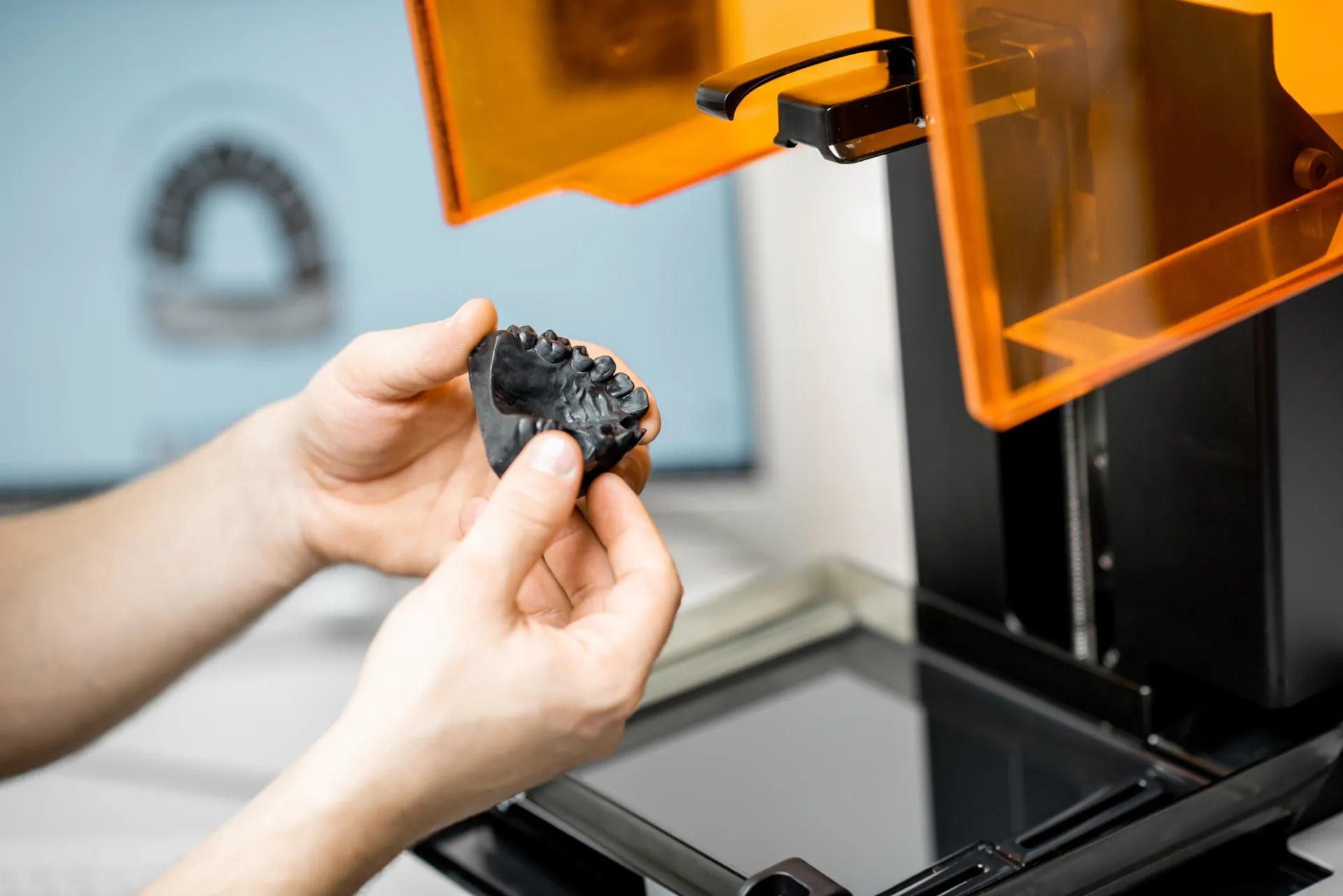

Dental and Medical SLA Resins

- Class I Biocompatible: Custom Medical Appliances Resin. Class I biocompatible resins are commonly utilized in custom medical equipment applications such as surgical guides. The advantage of SLA parts using Class I biocompatible resins is that they can withstand sterilization from an autoclave, which allows them to be utilized in medical operating rooms. Moreover, these resins offer a high degree of precision and smooth surface finishes, which makes them great for surgical applications.

- Class IIa Biocompatible: Dental Long-Term Biocompatible Resin. Class IIa biocompatible resins are specifically designed for long-term dental and orthodontic applications. In fact, these resins can be in contact with human bodies for a maximum of one year. These resins are resistant to fracturing, making them ideal for orthodontic retainers.

Castable SLA Resins

-

Castable Resin Used to Make Jewelry. Castable SLA resins are excellent for 3D printing parts with intricate details and smooth finishes. Additionally, castable resins will burn out cleanly without leaving behind residue. These properties make castable resins great for use in producing small, intricate products such as jewelry.

The Advantages of SLA 3D printing

Isotropy

SLA 3D printing produces highly isotropic parts. This isotropy is enabled by the ability to carefully control multiple key factors through the integration of material chemistry with the SLA process. Specifically, SLA resins form covalent bonds during printing, but the print stays in a semi-reacted “green state” from one layer to the next. During the green state, SLA resins maintain polymerizable groups which form bonds across layers. This ensures the part is isotropic upon final cure. This isotropy means that, at a molecular level, there is no variation across X, Y, or Z planes. Isotropy is beneficial because it gives parts more reliable mechanical properties for their intended applications.

Watertightness

SLA 3D printed parts and prototypes offer continuous surfaces no matter if the print has internal channels or solid features. This continuity ensures that SLA parts and prototypes are watertight for critical applications involving fluid or airflow. Examples of watertight applications include biomedical, automotive, and prototypes of consumer products such as kitchen appliances.

Precision and Accuracy

SLA provides the tightest tolerances of any 3D printing technology available on the market. One of the great advantages of SLA 3D printing is that its heated resin tank and contained build environment ensures near-identical conditions for each print. Moreover, SLA utilizes light instead of heat, which means the process occurs near room temperature. As a result, SLA parts and prototypes aren’t as affected by thermal contraction and expansion compared to other manufacturing methods. All of these characteristics of SLA lead to a high level of accuracy and repeatability.

Smooth Surface Finishes

SLA 3D printing is the leading additive manufacturing method for producing a smooth surface finish. In fact, surface finishes produced by SLA 3D printing are comparable to that of injection molding, CNC machining, and extrusion. These smooth surface finishes are also very beneficial for decreasing post-processing time. That’s because SLA prints have smooth surface finishes coming right out of the printer. With SLA, since the most recent layer printed interacts with the previous layer, the typical staircase effect found in other 3D printing methods is smoothed.

Get multiple quotes for your parts in seconds