Select the Right 3D Printing Material

In order for your prototype or part to function properly and look the way you want it to, you must carefully select the right 3D printing material.

Introduction: How to select the right 3D Printing Material

3D printing can be a great solution for prototyping and manufacturing a wide range of different parts. For many applications, 3D printing can be done faster and more cost-effectively than other manufacturing methods.

While deciding which specific 3D printing process is right for your prototype or part, it’s equally important to carefully consider which 3D printing material would be the best. Depending on the design and the goals that you have for your part, you must factor in the various mechanical properties and aesthetic characteristics that your part will need when it comes to 3D printing materials.

Overview of Different Types of 3D Printing Materials

Select the right Plastic 3D Printing Material

-

ABS requires ventilation and a heated bed to print. This durable plastic is impact and heat resistant.

- PLA is the easiest plastic to FDM print. PLA offers many desirable properties including strength and being odorless and biodegradable. On the other hand, PLA is brittle and has less resistance to chemicals and heat.

- PETG can be printed at lower temperatures, which increase production speed. PETG is also notable for being food-safe, as well as chemical and moisture resistant.

- TPU is a highly flexible plastic, which makes it great for vibration dampening and impact resistance.

- PVA provides a support material that dissolves in water.

- HIPS provides support material for ABS and dissolves in chemical limonene.

- Carbon fiber, Kevlar, and fiberglass composites are very durable and strong. These composites are printed on industrial-grade FDM 3D printers.

- Standard resins offer a smooth, matte surface finish and high resolutions.

- Nylon 12 is notable for being resistant to many factors including solvents, heat, and water. It’s resistant to impact, durable, and quite strong.

- Nylon 11 is quite similar to Nylon 12 except that it’s more elastic and resistant to impact. The tradeoff for these properties is that it’s not as stiff as Nylon 12.

- Nylon composites are Nylon materials that have added aluminum, glass, or carbon fiber to increase strength.

Select the right Metal 3D Printing Material

- Titanium is a lightweight metal that provides strength and resistance to corrosion and heat.

- Stainless steel offers corrosion resistance, as well as high ductility and strength.

- Aluminum is a lightweight metal that offers desirable thermal characteristics, as well as being strong and durable.

- Tool steel is a very strong and durable metal that is abrasion resistant.

- Nickel alloys offer resistance to corrosion and heat, as well as high tensile strength.

Which Materials are Compatible with Different 3D Printing Processes?

Select FDM for 3D Printing

FDM stands for fused deposition modeling. FDM is often used for prototyping because of its speed and affordability. Basic FDM offers lower accuracy and resolution compared to other 3D printed plastics. As a result, FDM is not ideal for intricate or complex parts.

Materials that are compatible with FDM 3D printing include:

- ABS

- PLA

- PETG

- Nylon

- TPU

- PVA

- HIPS

- Composites – Carbon fiber, Kevlar, fiberglass

SLA 3D Printing

Stereolithography—commonly called SLA—is a 3D printing process the offers very high degrees of accuracy and resolution. Additionally, SLA produces surface finishes that are smoother than all other plastic 3D printing processes. Parts that are printed using SLA can be painted and polished after printing.

Materials that are compatible with SLA 3D printing include photopolymers such as:

- Standard Resins

- Filled Resins

SLS 3D Printing

SLS stands for selective laser sintering. SLS 3D printing is known for making highly functional parts with great strength. The SLS 3D printing process is affordable and highly efficient, which makes it ideal for many different applications including rapid prototyping and custom parts manufacturing. SLS can also handle the intricate features of complex prototype and part designs.

Materials that are compatible with SLS 3D printing include:

- Nylon 12

- Nylon 11

- TPU

- Nylon Composites

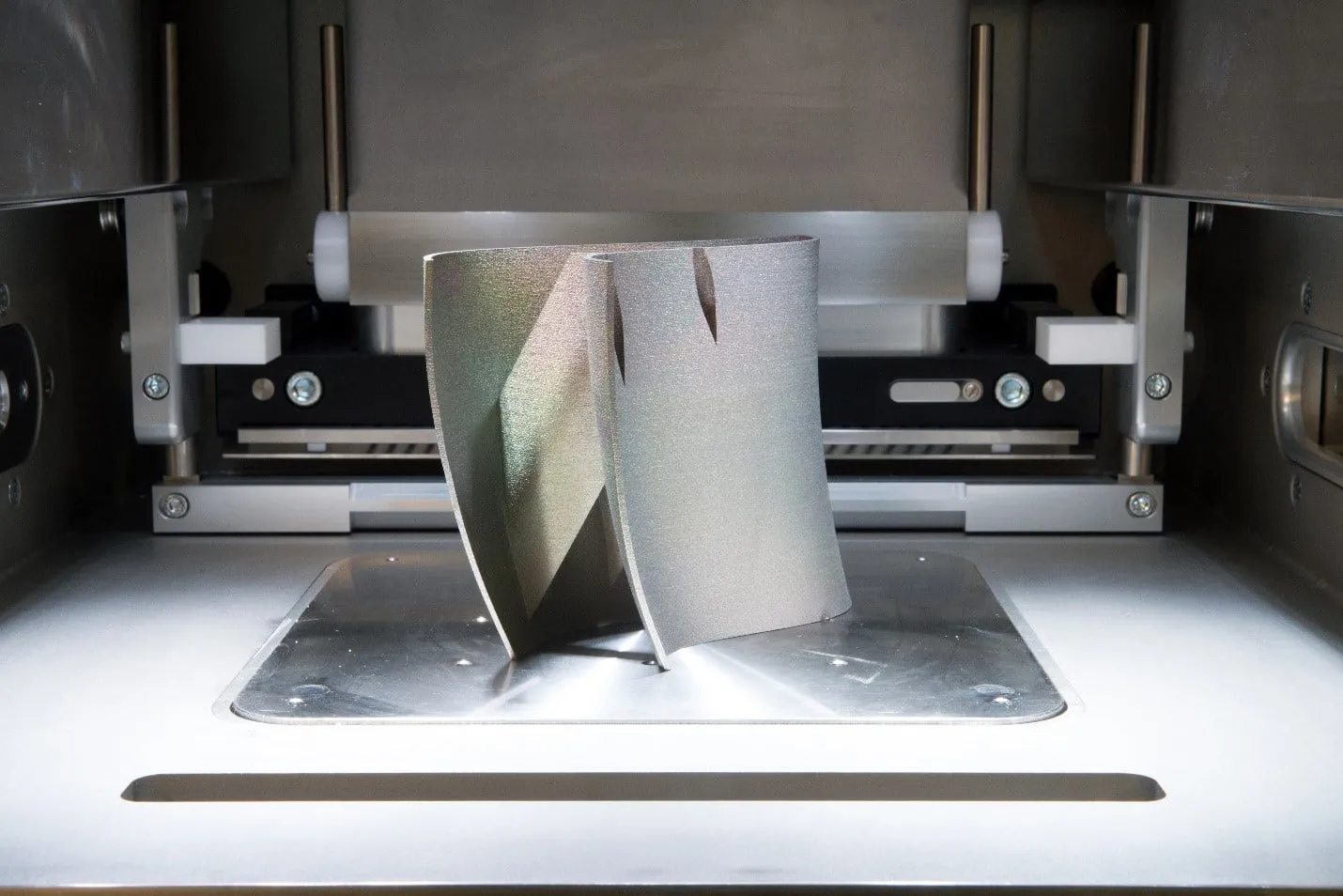

Select Metal for 3D Printing

Specific metal 3D printing processes include:

- Metal FDM printing extrudes metal rods bonded together by polymers. Then the part is sintered in a furnace, which removes the binder.

- Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) processes use a laser to fuse metal powder particles layer by layer.

Materials that are compatible with metal 3D printing include:

- Titanium

- Stainless Steel

- Aluminum

- Tool Steel

- Nickel Alloys

What Types of 3D Printing Materials are Best for Your Product?

Here is an overview of some of the most common types of applications for different 3D printing materials:

- ABS is most commonly used to 3D print functional prototypes.

- PLA is often used for making concept models.

- PETG is a great 3D printing material for products that need to be waterproof. It’s also useful for snap-fit components.

- TPU is great for making prototypes that need to be flexible.

- Carbon fiber, Kevlar, and fiberglass composites are quite versatile. They can be used to 3D print functional prototypes, as well as jigs, tooling, and fixtures.

- Standard resins are most commonly used to make concept models.

- Nylon 12 can be useful for medica devices, functional prototypes, and parts.

- Nylon 11 is used for similar applications as Nylon 12.

- Nylon composites are great for parts with structural functions and also for functional prototyping.

The Best 3D Printing Material to select for Beginners

If you are new to 3D printing, the reality is some 3D printing materials are more difficult to work with than others. For this reason, it’s helpful to know which 3D printing materials are easier to select for beginners to work with.

Most beginners find PLA and PETG to be the best materials to start with. Let’s take a closer look at each:

- PLA can be printed using a standard configuration, which makes things easier for beginners. PLA is also very affordable, which makes it less costly if a beginner makes a mistake and needs to start over.

- PET-G is easy to print and has the added advantage that it contains similar properties to ABS, which is a little bit more challenging of a material for beginners.

Get multiple quotes for your parts in seconds