PLA vs. ABS: Which Filament Should You Use?

Are you trying to decide between PLA vs. ABS filaments for your 3D printed prototype or part? We have all the answers you need here!

Discover SOLIDWORKS 3DEXPERIENCE for Makers

Introduction to PLA vs. ABS

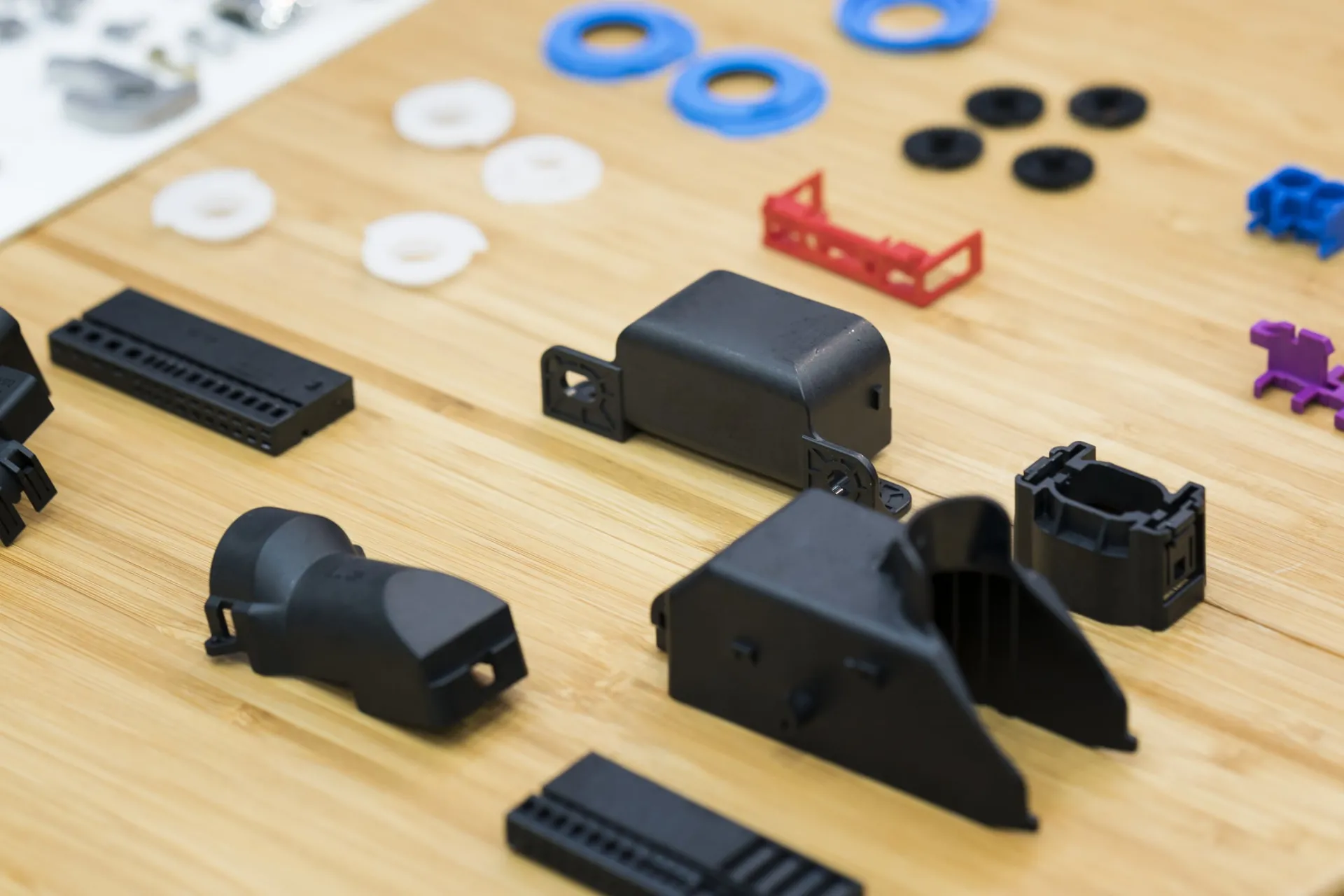

3D printing is an additive manufacturing process used in a variety of applications. It has proven itself to be tremendously beneficial for everything from rapid prototyping to toys, medical devices, and much more. When it comes to planning and designing your next 3D printed part or prototype one of the most important considerations is what type of 3D printer filament to use. For many designers, the decision often revolves around the question of whether PLA vs. ABS filaments is better for their application.

PLA and ABS are some of the most common filaments in use today when it comes to 3D printing. In this article we take a closer look at what PLA and ABS filaments are, their key properties, and which filament is best for your part or prototype.

What are PLA and ABS Filaments?

PLA stands for Polylactic Acid. PLA is a thermoplastic material that comes from biodegradable sources such as sugarcane and cornstarch. As a bioplastic, PLA is a commonly used for many different applications. PLA is also commonly used in 3D printing as it’s stiffer than ABS and nylon. As a tradeoff, PLA has a low level of heat and chemical resistance.

ABS stands for Acrylonitrile Butadiene Styrene. ABS is a thermoplastic material commonly used for injection molding. Compared to PLA, ABS has more desirable mechanical properties and is also more durable and lightweight. However, ABS is harder to use in 3D printing compared to PLA.

How Accurate is 3D Printing with PLA Compared to ABS?

In most cases, the level of complexity of the model and the particular calibration of the printer determines the accuracy of 3D printed parts. Additionally, PLA and ABS filaments create parts with a very high degree of dimensional accuracy. In fact, for interlocking components printed with PLA or ABS, tolerances of 0.5 mm and a minimum wall thickness of 1-2 mm are very much doable while still ensuring that the components have sufficient strength. It’s also worth mentioning that since PLA has a lower printing temperature, it's less likely to warp after cooling compared to ABS. Therefore, PLA is superior to ABS when it comes to producing intricate features and sharp corners.

Understanding the Strength of PLA and ABS Filaments

The tensile strengths of PLA and ABS filaments are actually quite similar. This characteristic makes them excellent candidates for rapid prototyping. While the tensile strength is comparable, some engineers prefer ABS over PLA when it comes to ductility. Compared to PLA, ABS offers more flexural strength and elongation before it breaks down. As a result, ABS is also a great option for final part production. However, if you simply need a filament for prototyping purposes, PLA is a great choice since form is more important than function. In summary, PLA filament is an ideal choice for parts that will not encounter high amounts of physical force. On the other hand, if your application will need to withstand external physical forces ABS is the preferred filament.

What are the Differences in Surface Finish for PLA vs. ABS?

Regardless of whether you use PLA or ABS to 3D print your part, you will still be able to see layers on your finished part. From aesthetic perspective, printing with PLA typically provides a glossy finish whereas ABS printed parts have a matte finish. For designers who want to print with ABS, but still achieve a smooth, glossy finish, apply acetone in post-processing. For engineers who want an even smoother finish beyond PLA, you can also use sanding and machining in post-processing, but you will need to be much more delicate with these processes.

Are PLA and ABS Filaments Heat Resistant?

ABS has a glass transition temperate of 105°C whereas PLA’s is 60°C. For this reason, any part applications in high temperature environments should be 3D printed with ABS instead of PLA. When subjected to temperatures of 60°C or higher, the structure of PLA filaments can be easily compromised resulting in deformities. This is particularly true if the PLA part is experiencing higher amounts of physical force.

Is PLA or ABS Better for Your Application?

Choosing between ABS or PLA filaments for your 3D printed prototype or part depends on the specific requirements and use case for your application. It is by no means a one-size-fits-all decision and you should carefully weigh all the factors involved in each filament in order to make the best decision.

If aesthetics is one of your top priorities, PLA filaments are a good choice especially if your part has intricate or complex features. These characteristics make PLA ideal for prototypes. Additionally, toys, containers, and architectural mockups contain PLA.

For parts that need to be stronger and more heat-resistant, ABS is preferable. Plus, ABS filaments are more resistant to corrosion compared to PLA filaments. ABS is great for applications involving moving parts, as well as for printing products such as phone cases and suitcases.

In terms of cost, there is not much difference between PLA and ABS filaments. Their pricing is some of the most economical amongst 3D printing material. For example, 10 meters of PLA and ABS each cost around five dollars. Color, brand, and shipping costs determine the price of PLA and ABS filaments.

Get multiple quotes for your parts in seconds