Laser Cutting: Advantages & Inconvenients

Advantages and Disadvantages of Laser Cutting Operations. Learn more now!

Introduction

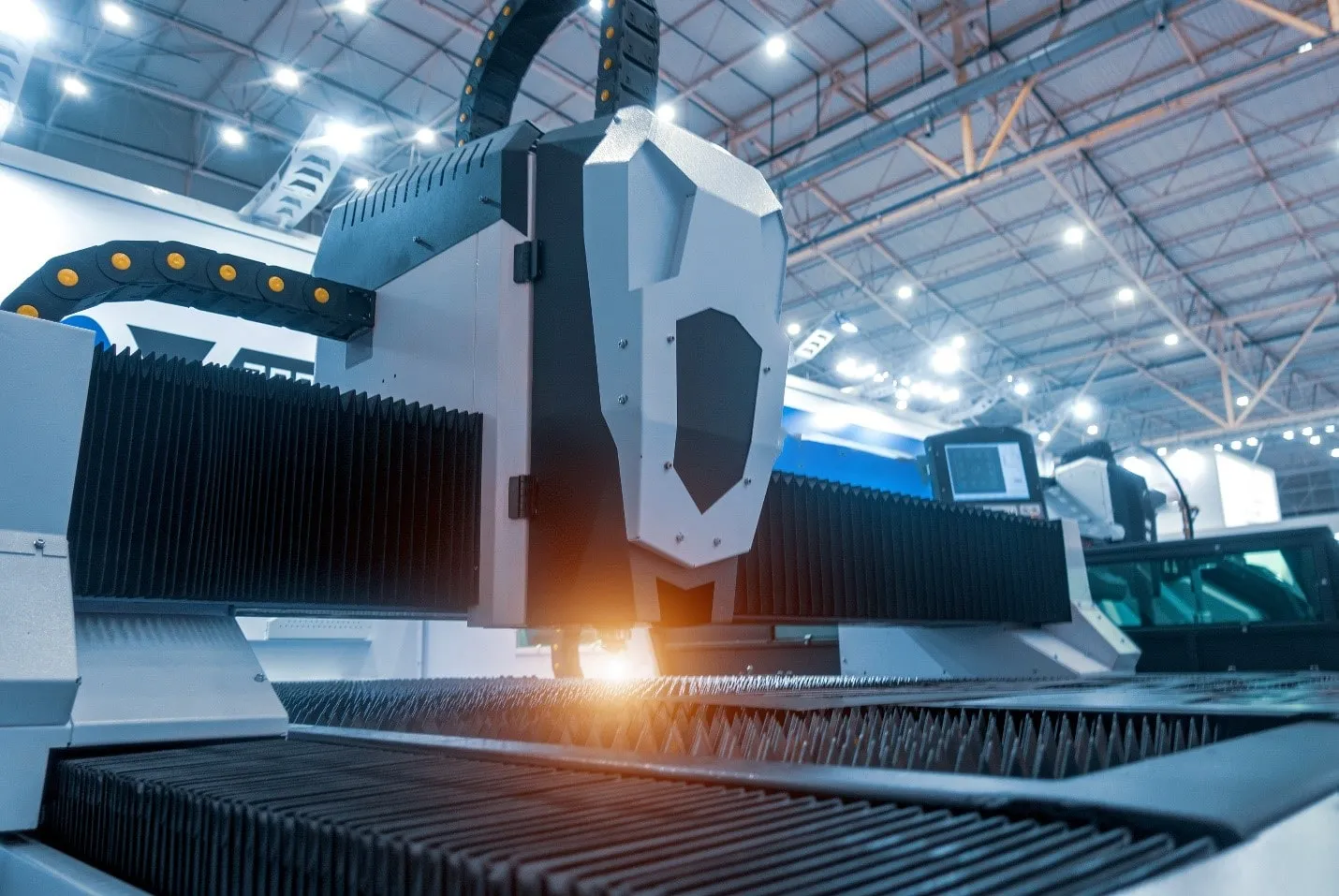

Laser cutters are high-energy, focused laser beams that cut sheets of steel, wood, plastic, and other materials into two-dimensional parts in the manufacturing and hobbyist arenas. "Laser" is a commonly used term for "Light Amplification by Stimulated Emission of Radiation," which explains the physical science necessary to generate laser light. It is a widely adopted technology suited for the mass production of precise two-dimensional parts.

The laser-cutting process utilizes a computer-generated program called a G-code, a set of machine-readable instructions instructing the machine where to move the laser-cutting head. Once the program is loaded, the material may require additional preparation before loading material onto the cutting bed. Once the material is loaded, a small, high-energy light beam is initiated and focused on one spot to heat the material and initiate the cutting process. As the material heats, the laser is directed to cut multiple parts using a series of mirrors and lenses. The intense heat melts and often vaporizes material as it is directed across the bed while cutting parts from the material sheet. Parts are removed and may be further processed.

Laser cutters are used in a range of applications, including engraving, laser welding, tube cutting, and sheet metal and plate cutting. There are several different types of lasers and methods used for Laser Cutting. These include the following:

Types of Laser Cutting:

- CO2 Lasers – This laser utilizes carbon dioxide (CO2), Helium (HE), and Nitrogen (N) to optimize the cutting process; Nitrogen help to amplify the energy while Helium helps to dissipate the remaining energy after the cut. These lasers are often used with metals plate but struggle with materials that have high reflectivity and thermal absorption.

- Fiber Lasers – Flexible fiber optic cables carry photons to produce the beam with the assistance of rare earth elements such as erbium, neodymium, thulium, or yttrium. Each element produces different wavelengths for varying applications. These lasers are best suited for cutting reflective materials like brass or gold and, due to the flexibility of the fiber cable, can be mounted to robotic arms.

- Nd:YAG lasers – This powerful, high-density laser is often used for marking and etching. This laser utilizes a neodymium (Nd) doped yttrium aluminum garnet crystal (Y3Al5O12) which aids the photon acceleration to create a high-intensity beam. Nd:YVO lasers operate similarly with improved power stability, reduced heat, and greater laser intensity.

Laser cutters are used to cut a wide range of materials. The most commonly cut materials are listed as follows:

- Acrylic – This transparent, rigid material is also known as polymethyl methacrylate or PMMA.

- Aluminum – A reflective material, fiber lasers cut most types of aluminum.

- Brass – Best cut with a fiber laser.

- Cork – Cork can be easily laser-cut or engraved.

- Felt – A fabric that cuts easily, especially if 95%+ wool.

- Hardboard – Easy to cut but releases fumes from adhesives.

- Leather – This material is easily cut or engraved, often for personalized items

- Stainless Steel (SS) – Fiber lasers are best suited for SS.

- Steel – This includes mild steel and carbon steel. High-power lasers can cut up to 20–25 mm plate thickness.

- Wood – Low-power lasers are used for the different types of wood.

- Other materials include:

- Adhesives

- Coated Fabrics

- Foils

- Films

- Foams

- Gaskets

- Labels

Laser cutting can produce toxic gasses or has difficulty with certain materials. These materials that should avoid the laser-cutting process include:

- High-Density Polyethylene (HDPE)

- Laminated Fiberglass

- Polycarbonate (PC)

- Polystyrene and Polypropylene Foam

- Poly Vinyl Chloride (PVC)

- Polycarbonate (PC)

Caution is required when operating laser cutters. Like most industrial machinery, there are dangers (listed below):

- Burning – Certain materials may burn or scorch if not processed correctly.

- Eye Damage – Reflective materials run the risk of laser reflection into the eyes, which can cause severe eye damage.

- Sharp Edges – Depending on several factors, some parts may have sharp edges that can cause severe cuts if not handled correctly. Additional deburring or tumbling may be required.

- Toxic Gas – Some materials release toxic or corrosive fumes during cutting.

This article explores the fundamentals of Laser Cutting, including its Advantages and Disadvantages.

Laser Cutting: Advantages

There are many advantages to the widely popular laser-cutting technology. These include the following:

- High Precision – Laser cutters are incredibly accurate and precise.

- High Speed – Although the rates vary by material type and thickness, the process can be performed at high speeds.

- Automation – The process is highly automation and can include material handling systems with little operator involvement.

- Clean – Laser cutting is typically a clean procedure and does require cutting fluids or other chemicals.

- No Tooling Costs– Not additional tooling or work holders are required.

- Limited Post-Processing – Once parts are cut, little else is often required.

- Material Versatility – Can cut many materials.

- Versatility – Can engrave or cut materials.

Laser Cutting: Disadvantages

The disadvantages of laser cutting are listed below:

- Limited Material Thickness – Lasers are limited as to the thickness they can cut. The maximum is typically 25 mm.

- Toxic Fumes – Certain materials produce dangerous fumes; therefore, ventilation is required.

- Power Consumption – Laser cutting consumes large amounts of power.

- Cost – A large capital outlay for laser cutting equipment is required, especially compared to alternative technologies such as flame or plasma cutters.

- Maintenance – Certain laser technologies, such as CO2, have more significant expenditures for frequent replacement parts.

- Process Parameters – The process must be refined, or discoloration or burning may occur.

- Danger – The laser can cause severe burns or worse.

- Production Rates – Rates vary with different material types and thicknesses.

Get multiple quotes for your parts in seconds