How Strong Can 3D Parts Be?

3D Printing and product strength. Learn more now!

Introduction

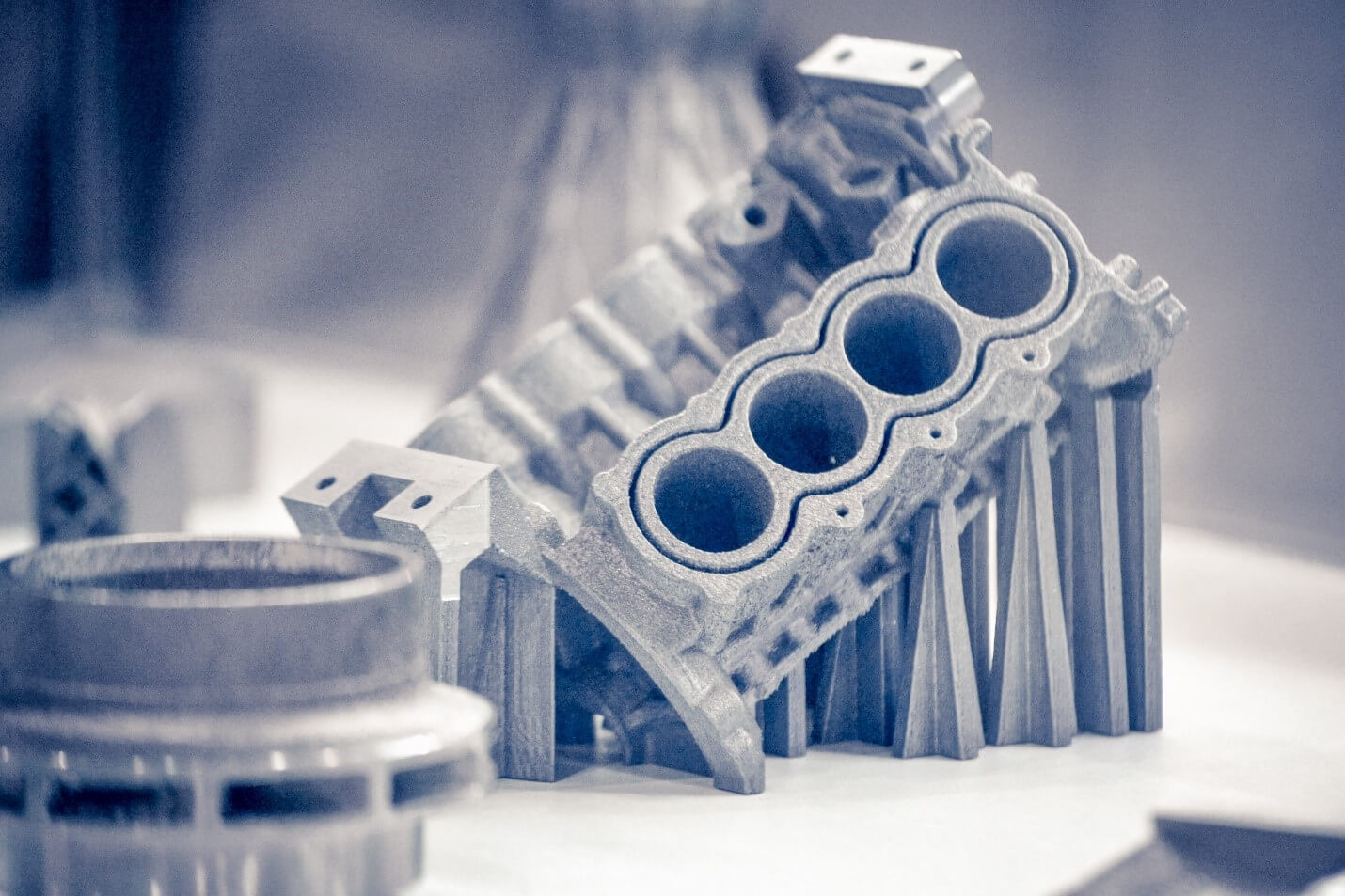

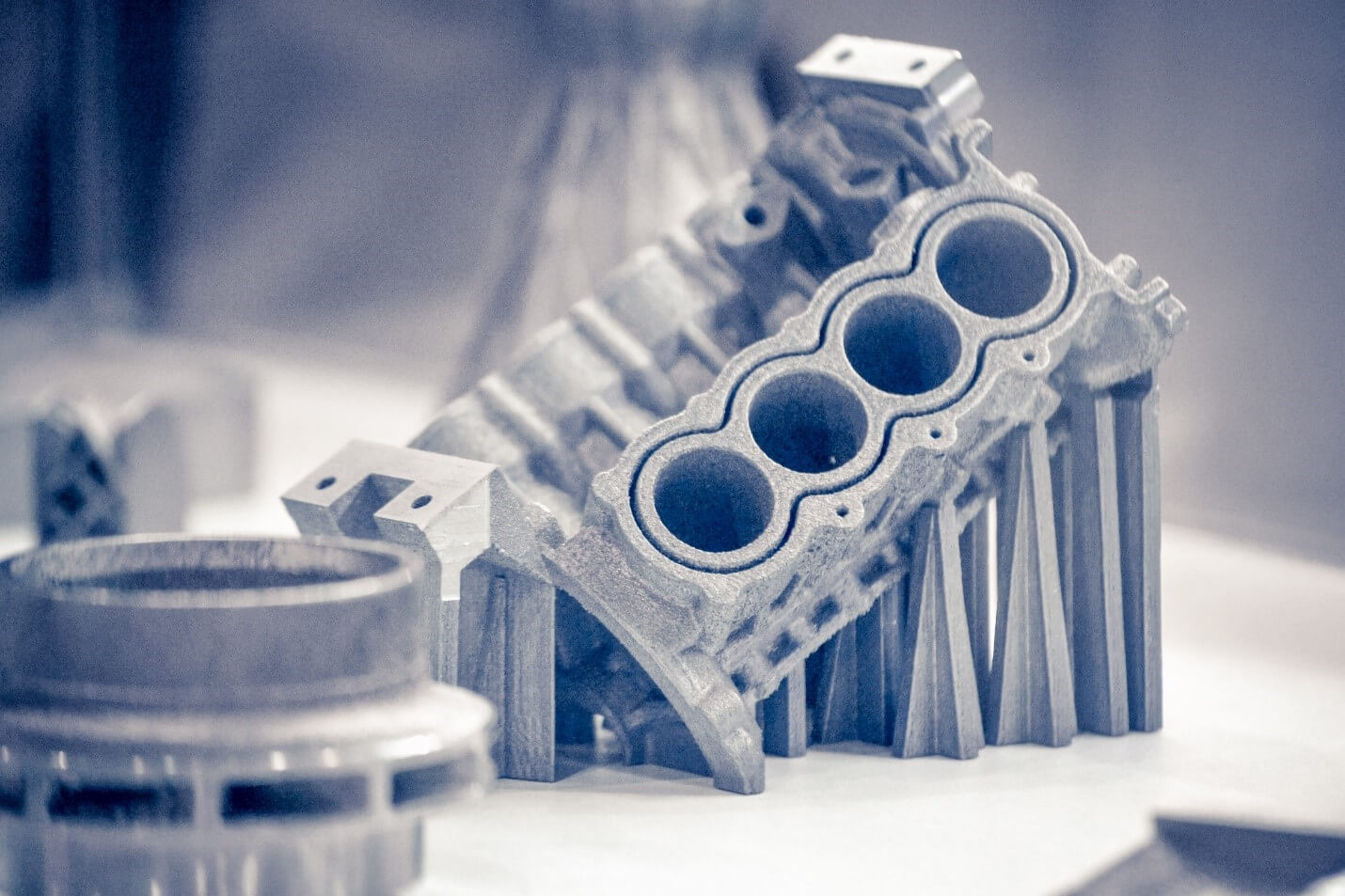

3D printing is an additive manufacturing process of creating three-dimensional solid objects from a digital 3D drawing, and successive layers of material are placed to form the product form. This technology is used in a wide variety of industries where product strength is critical, including automotive, aerospace, medical, and consumer products. The bond strength of the successive layers is crucial to the overall strength of the products, as is the material, printer orientation, and internal structure.

This article discusses the strength of 3D printed parts and what improves product strength. The article reviews the latest materials and other factors contributing to the overall strength of 3D-printed products. There are several factors for evaluating product strength that is also considered.

How to Make 3D Printed Parts Stronger?

The strength of 3D printed parts depends on several factors, including the material used, the structural design, part orientation, and the printing process. Strength can vary significantly with 3D materials and the printing process. For example, ABS plastic is a standard 3D printing material that is strong and impact-resistant but not as strong as metals such as aluminum or steel.

While Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA) are among the most common thermoplastics used in 3D printing, the strongest parts use industrial-grade thermoplastics such as Polycarbonate, ABS, or Nylon. These materials are generally stronger than the PLA and other plastic filaments used in consumer-grade 3D printers. Industrial-grade thermoplastics are extremely heat-resistant and can produce parts with great detail and durability.

Other factors include the 3D printer settings and post-processing methods. These may include:

- Infill Percentage – This is the percentage solid of a printed par. A printed part with 0% infill would be completely hollow, while a 100% infill would be completely solid.

- Layer Height – Layer height is the thickness of each printed layer. This thickness directly impacts the product's strength as thinner layers will produce a more robust product, while thicker layers tend to yield a weaker product.

- Part Orientation – Surprisingly, part orientation is a more significant factor than one would assume. The bond between the layers is vital to the overall product strength, so one must consider the unique product stresses and performance requirements to optimize the orientation and product strength.

- Post Processing – Techniques such as sanding, painting, and coating typically improve the strength of the 3D-printed object. These operations fill in any irregularities in the product surface.

- Print Speed – Slower print speeds produce stronger products, allowing optimal heating and curing.

- Shell Thickness – The typical 3D-printed part has a shell thickness of only 1.0 - 1.5 mm. Increasing the thickness can significantly improve a part's tensile and impact strength.

The Strength of Material Used to Create 3D Printed Parts

Material composition is vital to product strength. The most commonly used materials for 3D printing are plastic, metal, and ceramic. Generally, plastic materials used in 3D printing are not as strong as metals and ceramics, but they are strong enough for a variety of applications.

Overall, Polycarbonate is generally considered the strongest 3D printed filament, but there are several methods by which product strength is ascertained. The numerous strength measurements should be considered to optimize part production.

These include:

- Tensile Strength – This term refers to the material stiffness and the maximum stress required before the part breaks or deforms.

The strongest materials for tensile strength include:

-

- Polycarbonate

- PVA (Polyvinyl Alcohol)

- PETT (Polyethylene Terephthalate Glycol)

- PEEK (Poly Ether Etherketone)

- Carbon Fiber

- Elongation (Ductility) – Elongation is the extent a material can be plastically deformed. This term is also called ductility and measures with similar equipment used to evaluate tensile strength. A high ductility level refers to a material that can be stretched or elongated into a thin wire shape without breaking. A low ductility indicates that the material will fracture if deformed under a heavy load.

The materials with the highest levels of elongations are:

-

- Flexible TPE (Thermoplastic Elastomer)

- Flexible TPU (Thermoplastic Polyurethane)

- Hardness – Hardness is generally separated into nine categories ranging from A to K on the Rockwell scale, a commonly used method for measuring the hardness of materials used in machining.

The materials with the highest hardness levels include:

-

- Carbon Fiber

- Nylon

- ABS (Acrylonitrile Butadiene Styrene)

- Impact Resistance – Impact resistance measures the resistance to deformation or breakage when subjected to a sudden force or impact.

Materials with the best impact resistance include:

-

- Polycarbonate

- Nylon

- PETG (Polyethylene Terephthalate Glycol)

- ABS (Acrylonitrile Butadiene Styrene)

- TPU (Thermoplastic Polyurethane)

- Chemical Resistance – Chemical resistance is the ability of a material to counter degradation or damage when exposed to certain chemicals or chemical environments. This measurement varies by chemical, specific environment, ambient temperature, and different types of stresses.

The materials with the best chemical resistance include:

-

- PP (Polypropylene)

- PA (Polyamide, nylon)

- PE (Polyethylene)

- PEEK (Polyetheretherketone)

- PTFE (Polytetrafluoroethylene, Teflon)

- PVC (Polyvinyl Chloride)

- PVDF (Polyvinylidene Fluoride).

- ABS (Acrylonitrile Butadiene Styrene)

- Flexibility Comparison – Flexibility is defined by a material's ability to change from its original shape without losing structural integrity and with the ability to rebound back to its original form.

The most flexible materials are:

-

- Flexible TPE (Thermoplastic Elastomer)

- Flexible TPU (Thermoplastic Polyurethane)

- Nylon

- Polycarbonate

- Heat Resistance – Material heat resistance measures a material's ability to withstand high temperatures without being damaged or degraded. It is a crucial property for materials used in high-temperature applications such as aerospace, automotive, and power generation. Heat resistance is typically measured in terms of the material's melting point, thermal conductivity, and coefficient of thermal expansion.

- PAHT CF15 (high-temperature polyamide carbon fiber reinforced)

- PET-G (Polyethylene Terephthalate Glycol-modified)

- ABS (Acrylonitrile Butadiene Styrene)

- PP (Polypropylene)

- PP GF30 (Polypropylene 30% glass fiber)

- PA (polyamide)

Why Using 3D Printing Makes Sense for Strong Objects

Using 3D printing to make strong objects is logical because it is a cost-effective and efficient manufacturing method that has proven to meet or exceed the strength of conventionally manufactured products. 3D printing can create complex geometries with high accuracy and detail, enabling intricate details that would be impossible to achieve with traditional manufacturing methods. Additionally, 3D printing can produce parts with consistent quality and strength.

Get multiple quotes for your parts in seconds