How to Fix Broken 3D Parts

3D Printing and the Repair of Holes and Broken 3D Parts. Learn more now!

Introduction

3D printing makes three-dimensional parts from a digital file. The process is also known as additive manufacturing, as it adds layers of material one at a time to create an object. The layers occasionally do not bond and require repair. Misprints and defects sometimes occur and need repair. 3D printing is used in many industries, including manufacturing, engineering and design, architecture, automotive, aerospace, and medical.

How to Fix Holes in 3D Printed Parts?

The top layers of many 3D-printed parts can experience gaps and holes. You can increase infill percentages, use a denser infill pattern increase the number of slicer settings. Occasionally, the default settings are the solution. Otherwise, you may prefer to repair the problem.

There are several methods of repair, including the following:

- Use a filler material - This could be a viscous liquid plastic, wood filler, epoxy, or cyanoacrylate. Apply the filler to the hole and allow it to dry. Sand down any excess material and then apply a primer or paint to match the surrounding area.

- Use a patch – Cut a piece of plastic sheet material the same thickness as the part and glue it over the hole, using the same adhesive used to bond the plastic layers during 3D printing.

- Use a 3D printed patch – Depending on the hole size, you may be able to 3D print a patch. This is a more advanced method and requires you to create a 3D model of the patch before printing.

- Use a hot glue gun – Smaller holes can be filled with hot glue. This will dry quickly and provide a solid seal.

- Use a Support Structure - If the hole is too large to be filled with filament, you can use a support structure to reinforce the part. This could involve adding an extra layer of plastic or a metal rod to fill the gap.

- Apply Heat – Depending upon the material, applying heat to the area around the hole can help to fuse the edges of the hole. This will help reduce the hole's size and make it less noticeable. This method does not work with thermoset materials but can work with thermoplastics.

- Use a metal patch – If the hole is large or needs a strong, permanent seal, you can use a metal patch. This is done by cutting a thin metal to fit over the hole and then gluing it into place.

How to Fix Plastic 3D Printed Parts?

3D printing is an excellent method to create parts, but the more complex geometries tend to have problems during the first print, and we end up with broken or damaged 3D printed parts. The layers are also weak points that can be This can be due to weak points in the models, which sometimes can't be avoided, but what we can do is learn to fix these broken parts.

- Sanding – One of the most common ways to fix 3D-printed plastic parts is to sand them down. Sanding will help smooth out jagged edges and give the piece a more polished look. Use medium-grit sandpaper and sand in circular motions to smooth out the surface. You can also use a rotary tool such as a Dremel; to sand down any rough edges or bumps on the plastic 3D-printed part.

- Filling – If the part has significant gaps or holes, you can fill them with a plastic filler. This can help to make the piece look more uniform and help to strengthen it. Use an epoxy or plastic filler to fill in any gaps or cracks on the 3D-printed part. Apply the filler evenly and allow it to dry completely before proceeding.

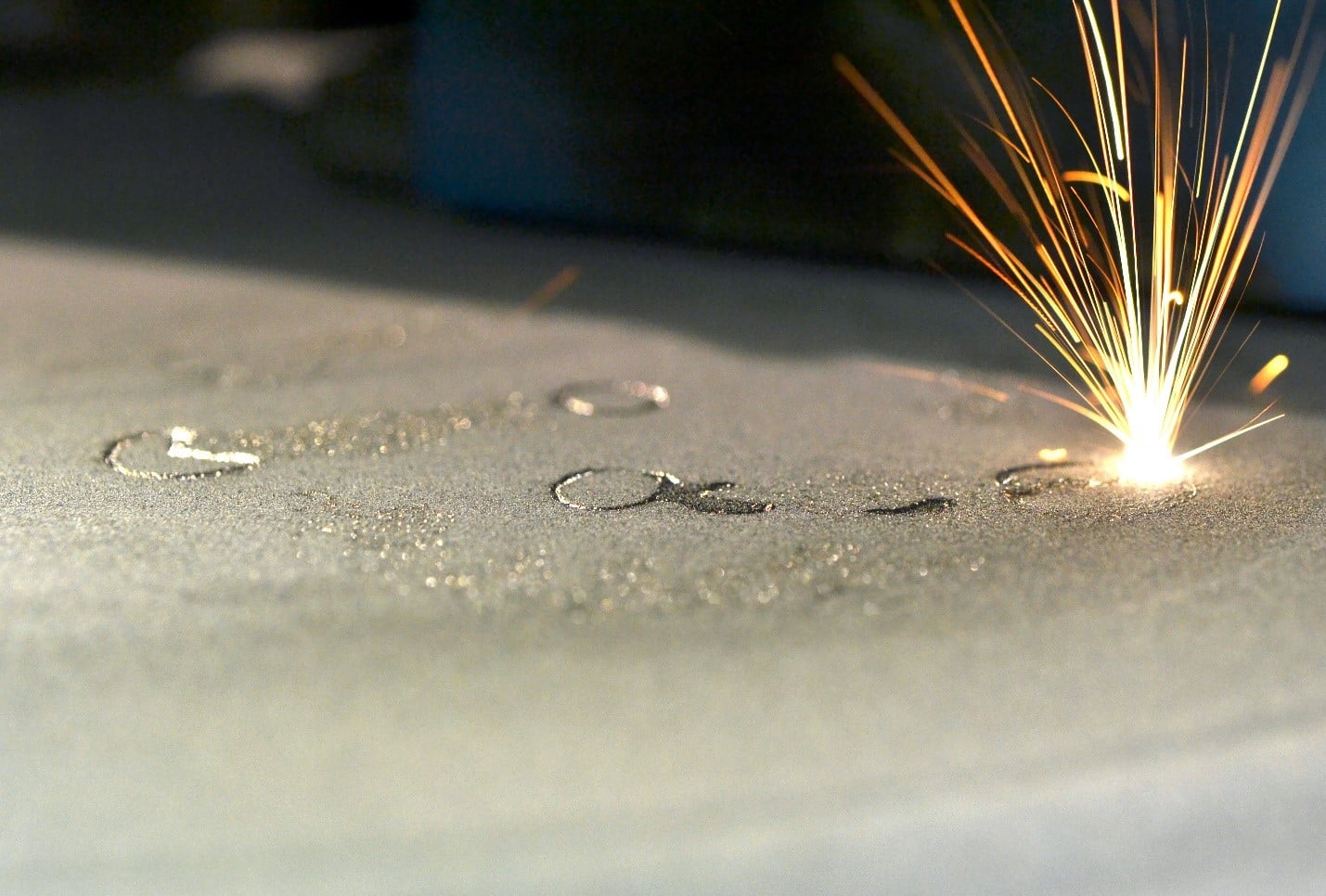

- Welding – A piece of filament from the same print and a soldering iron can be used to repair more minor defects. Traditional welding methods can be used to repair 3D-printed parts. The type of material and the size of the part are critical factors as different welding techniques may be used. For example, laser welding, TIG welding, or MIG welding may be used on plastic parts, while metal may require arc welding. It is vital to use the correct welding technique for the material and size of the 3D-printed part to ensure a solid and long-lasting repair. A filler material may also be necessary to achieve the desired strength and finish.

- Painting – Another way to fix 3D-printed plastic parts is to paint them. This can help to cover up any blemishes or imperfections and give the piece a more professional look. Use a plastic-compatible paint or primer to improve the overall appearance. Make sure to cover the entire surface in an even coat. Be sure to allow it to dry completely before handling.

- Heat-Treating – Heat-treating can help to strengthen 3D-printed plastic parts. Heat treating is usually done in an oven or with a heat gun. If the 3D-printed part is warped or deformed, you can use a heat gun or oven to heat the plastic until it returns to its original shape. A hot gun is ideal for melting materials like PLA for repairs. This will make it more durable and less prone to cracking or breaking.

- Post-Processing – Post-processing is a method to improve the finish of 3D-printed plastic parts. This can involve polishing, painting, or adding decorative elements to the part.

- Acetone Vapor Bath – If other methods don't work, you can try an acetone vapor bath. Place the 3D-printed part in a sealed container with acetone and heat it until the acetone evaporates, which will dissolve and smooth out the part's surface.

Some of the preferred filler materials include:

- Apoxie Sculpt Modeling Compound - Apoxie Sculpt combines sculpting clay and epoxy. It has a smooth, putty-like consistency that is easy to use use. It cures in 24 hrs. It is popular for sculpting miniatures, models, dolls, prototypes, and other intricate items. It is also lightweight and waterproof.

- Bondo Glazing Putty – This is the same material used in minor automotive repair, similar to the more commonly used body filler.

- Bondo Body Filler – A well-known two-part compound also used in auto body repair and the fabrication of customs body panels. It provides a strong bond and can be sanded or painted after drying.

- Elmer's Wood Filler – Designed originally for wood, Elmer's Wood Filler is composed of a combination of sawdust, glue, and pigment. It is easy to apply and can be sanded, stained, or painted after drying.

- Superglue - Superglue is an adhesive used to bond and attach a variety of materials. It is a strong, fast-drying glue often used for difficult-to-bond materials such as metal, glass, and plastic. The popular glue is often used with PLA, ABS & PETG, the more rigid materials. It is not particularly effective for flexible materials, including Nylon, TPU, and TPE.

Get multiple quotes for your parts in seconds