Renault Group Refactory

Renault Group Refactory - A 3d printing service at your service

Renault Group Refactory - About us

With more than 20 years of experience in the field of additive manufacturing, Renault Group has used its know-how as a car manufacturer to create a large-scale 3D printing centre at its Flins industrial site, near Paris. Now open to external customers, this centre can meet the needs of prototyping, unit or series production of parts for industry and the general public. Spread over an area of 500 m2, it is equipped with the latest generation of printing (FDM, MJF, SLA) and post-processing (finishing, colouring, painting) equipment.

Renault Group Refactory - Manufacturing process

3D printing

- Material extrusion - FDM

- Material jetting - MJ, NPJ, DOD

- Photopolymerization - SLA, DLP, VAT, CDLP

- Powder bed fusion - PBF, SLS, DMLS, SLM, MJF, EBM

Renault Group Refactory - Services

Ship

Geometry optimization

Surface treatment

STL repair

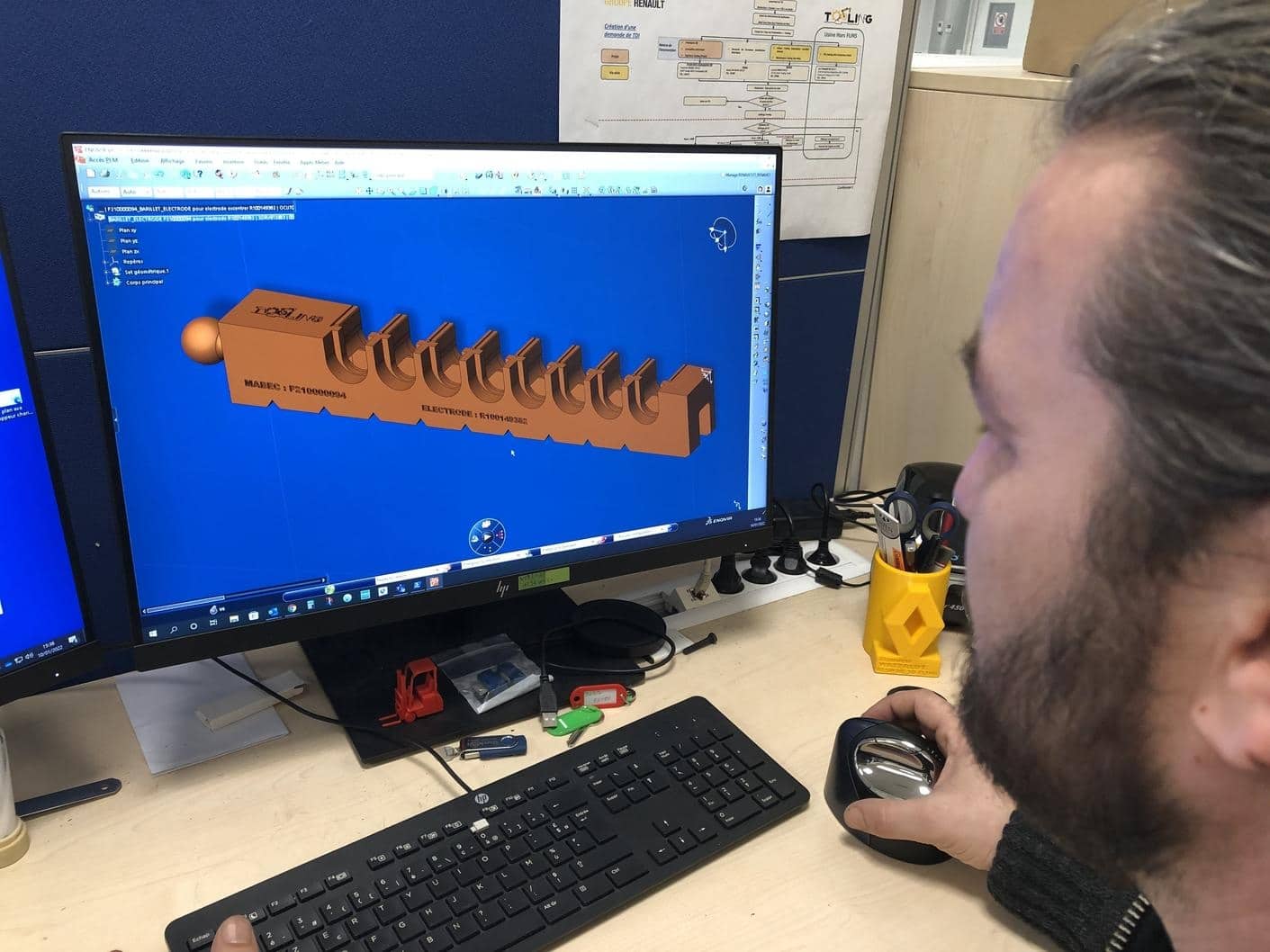

3D modeling

A few questions to Renault Group Refactory

- What are the advantages of 3DEXPERIENCE Make?

3Dexperience Make allows Renault Group to respond in an agile and reactive manner to the needs of manufacturers, who can thus benefit from its industrial know-how, automotive quality and automotive cost price.

- What is your area of expertise?

Our centre is specialised in the printing of polymer materials: PLA, ASA, ABS, PETG, TPU, PA12, ULTEM...

Our technicians and engineers offer their expertise to design, print and post-process your parts by applying the Renault Group's industrial know-how: quality, lead time and production cost.

- Who is your typical customer?

Our customers are start-ups, small and medium-sized companies as well as large industrial groups seeking our expertise to meet their prototyping and unit or series production needs.

Get multiple quotes for your parts in seconds