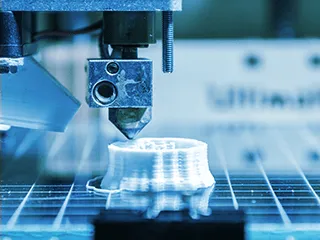

Launhardt GmbH - Industrial 3D printing

Order your part online with Launhardt, a specialist in industrial 3D printing. Directly available on 3DEXPERIENCE Make: the on-demand Manufacturing platform.

Launhardt - About us

Launhardt is a small but innovative production company with the focus on polymer processing. Founded in 1997 by Erich Launhardt with the focus on traditional extrusion of thermoplastic materials, the company has grown and eventually was taken over by the sons Dr. -Ing. Martin and Christian Launhardt in 2021. Since then, additive manufacturing plays an important role and with new materials, innovative post-processing and lots of ingenuity Launhardt has now taken a dominant role in the industrial 3D-Printing market.

Launhardt - Manufacturing processes

3D printing

- Material extrusion - FDM

- Material jetting - MJ, NPJ, DOD

- Photopolymerization - SLA, DLP, VAT, CDLP

- Powder bed fusion - PBF, SLS, DMLS, SLM, MJF, EBM

Launhardt - Certifications

- ISO 9001:2015

Launhardt - Services

Surface treatment

Geometry optimization

3D modeling

STL repair

Launhardt- A few questions to the team

- What are the benefits of 3DEXPERIENCE Make?

Using the platform of 3D Experience Make provides the possibility of customers to connect to the manufacturers themselves. There are two ways of cooperation, on the one hand customers can have easily a CAD calculated and the manufacturer can easily adjust the wishes with the possible manufacturing techniques. Moreover, with the quick calculation and manufacturing of single parts, the manufacturer has the possibility to fill up low dense buildjobs and if the parts quality is convincing, the customer may contact the manufacturer directly for larger series production.

- What is your area of expertise?

As provider of innovative powder materials for powder based additive manufacturing techniques such as Selective Lasersintering (SLS) and Highspeed Sintering (HSS), we also provide the service to directly manufacture complex 3D-parts with our materials. As we know our material the best, we can achieve best part quality and perfect customer’s solutions.

- Who is your typical customer?

Our typical customer has extraordinary wishes for their small series product with decisive part qualities such as very soft TPU material, without hydrolysis effects and high mechanical properties. Especially in times of supplier shortage due to the recent global developments the manufacturing of 3D-Printed parts as substitute for injection molded series parts does play an important role.

Get multiple quotes for your parts in seconds