3D Prod - 3D printing and rapid prototyping

3D Prod: 3D printing and rapid prototyping on 3DEXPERIENCE Make, the on-demand Manufacturing platform.

3D Prod - About us

Quentin Kiener, CEO of 3D PROD:

"Our job is to make 3D printed parts for our industrial customers on a daily basis.

We use a wide range of additive manufacturing processes : powder bed fusion, stereolitography, polyjet, multijet fusion, material deposition and vacuum casting.

We joined the marketplace over one year ago, it perfectly fits our digitalization strategy. I think that with the evolution of users behaviors and technologies, our business operations will always go through a fully automated quotation. Online, the service and the customer support will only take place afterwards if needed.

This is why it's important for us to be part of such a trading and collaborative platform."

3D Prod - Manufacturing capabilities

3D Prod is a French service provider specialist in plastic 3D printing. Learn more about 3D Prod manufacturing capabilities in the bullets points below:

- Founded in 2005 in the Vosges region of France

- 3D Prod is specialist in rapid prototyping for technical parts but also mockup and small series

- Production capability for big parts ( up to 2 meters)

- Focus on sustainability with 90% of internal waste being recycled

3D printing processes & materials

Powder bed fusion

- PBF

- SLS

- DMLS

- SLM

- MJF

- EBM

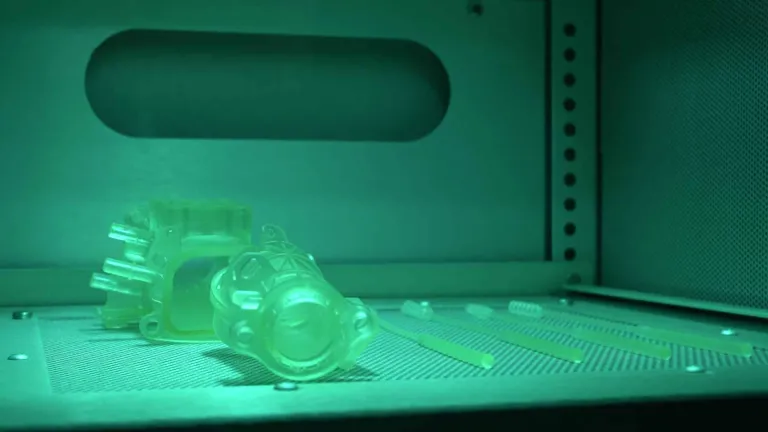

Photopolymerization

- SLA

- DLP

- VAT

- CDLP

Available with UV curable

Material jetting

- MJ

- NPJ

- DOD

Available with UV curable

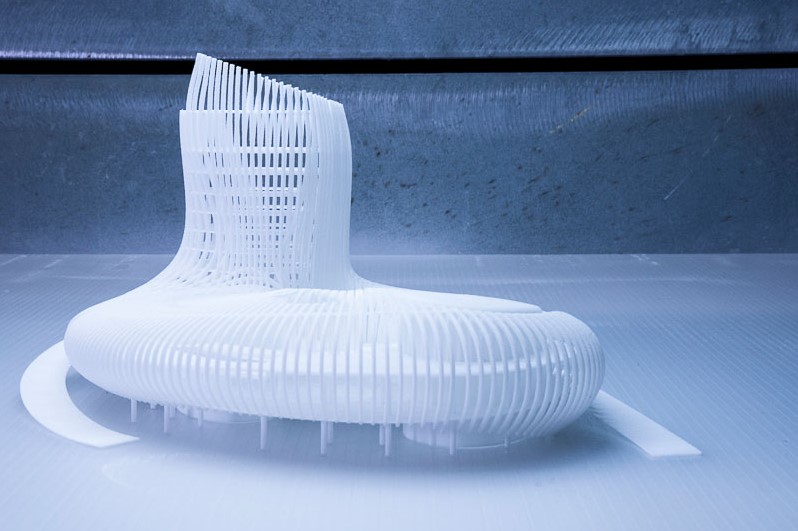

Focus on SLS 3D printing with 3D Prod

The SLS process is a 3D printing process. It involves sintering fine particles of polymer powder with the help of a laser to fuse them layer by layer.

The SLS process provides multiple benefits. First, it’s fast. Second is the quality of the parts, especially the ones with complex shapes. Third is the range of compatible materials. 3D Printing SLS has three main drawbacks. The first is space. The SLS process requires large, dedicated spaces. The second is the quantity of materials used. A lot of powder remains inside the powder cake that is not sintered and is no longer usable. This can increase the cost per part printed. The third is the cost of the technology which remains high for certain parts, especially the laser.

In terms of use, many sectors use the SLS process because it works with a range of materials and it can handle complex shapes when prototyping. 3D Printing SLS is actively used in various industries such as the aerospace, automotive, consumer products and architecture sectors for making detailed prototypes. In terms of functional parts, the SLS process is used in robotics and for drones. It’s also used in the medical industry to make implants and prosthetics which are tailored to patients.

3D Prod - Service

Pick up & Shipment

Surface treatment

3D modeling

STL repair

Get multiple quotes for your parts in seconds