ABS 3D Printing Service

ABS 3D printing services are an easy method of forming plastic parts. It is used in a wide variety of applications. Learn more now!

SECURE PAYMENTS

Via payment card or purchase order

PROTECTED IP

Your data is confidential and secure with us. Use your own Non Disclosure Agreement

INSTANT QUOTE

For 3D Printing and CNC Machining, get quote in few seconds.

Introduction: ABS 3D Printing Service

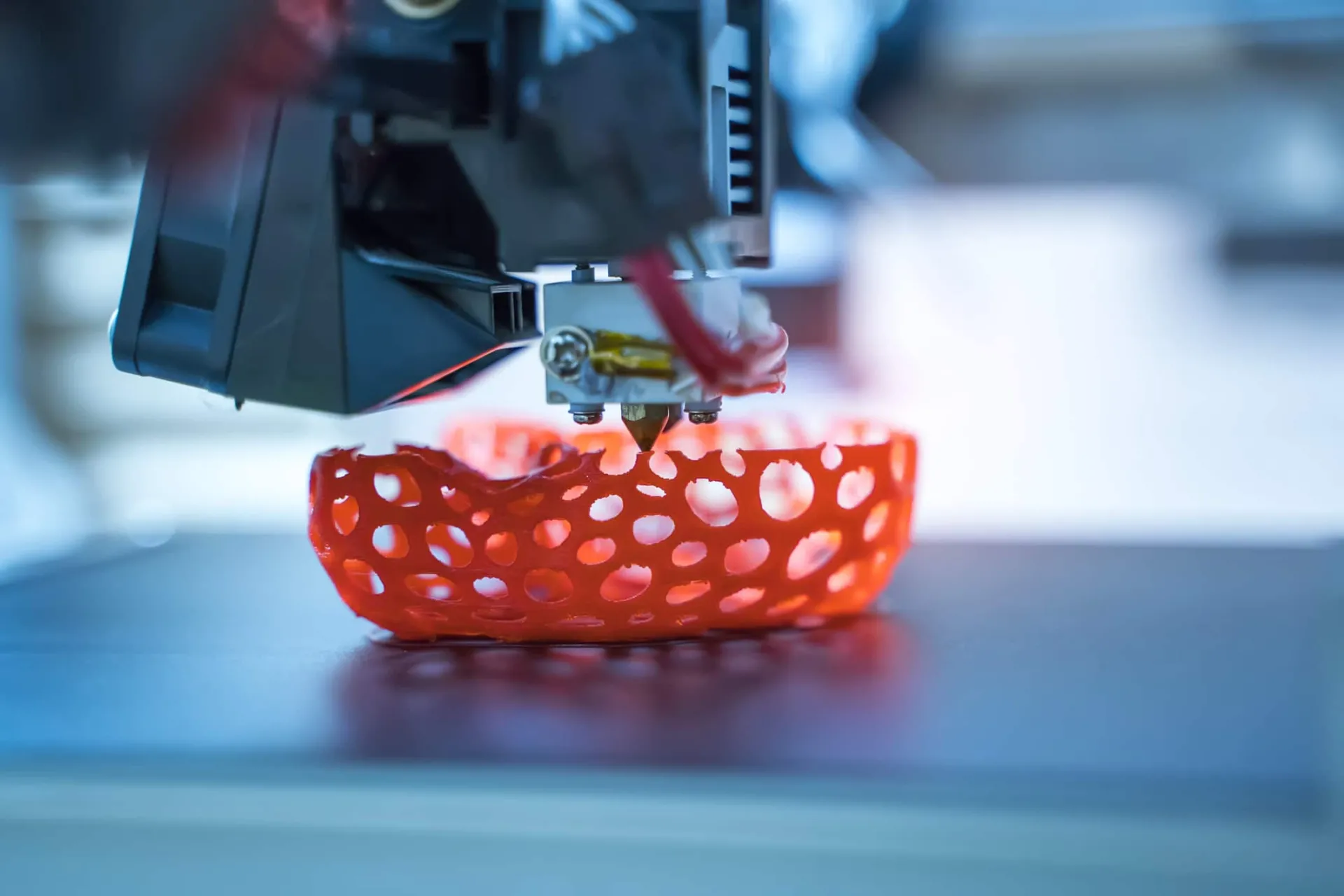

The rapid rise in 3D printing and printing services has improved the time to market for new products with rapid prototyping. 3D printing services are designed to be painless; a product design file is uploaded online to the service, a quotation is quickly provided, and the product is quickly printed and shipped. ABS is a popular plastic used in prototyping and production with 3D printers.

This article discusses ABS 3D Printing Services, their advantages, typical applications, and benefits.

Our online 3D printing services

Discover How 3DEXPERIENCE Marketplaces Boost Your Design to Manufacturing Process

You’re in good company. Thousands of leading companies from all industries use our solutions.

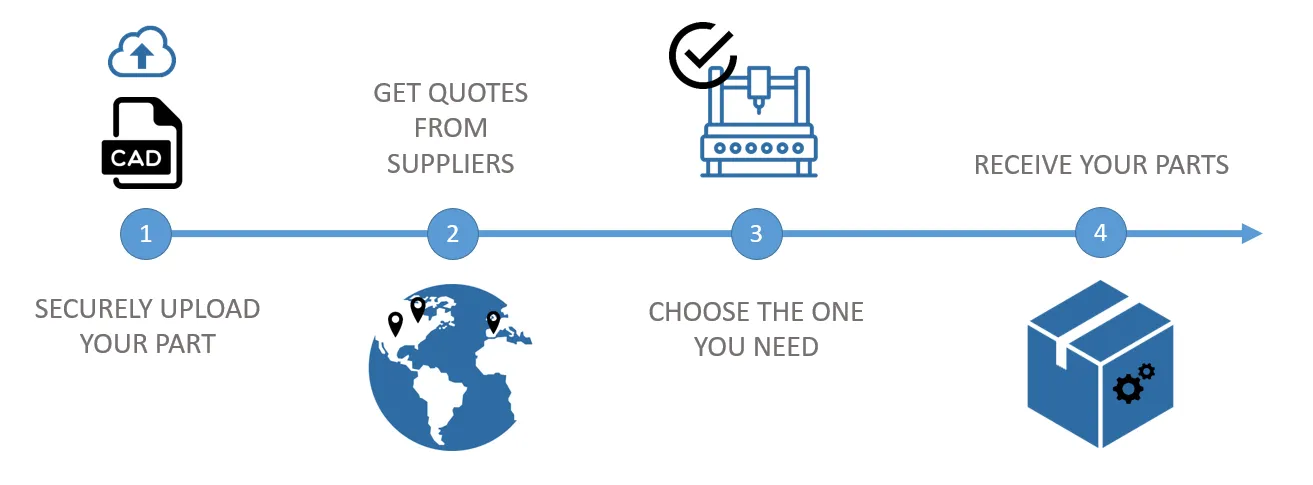

Online 3D Printing service: how does it work?

Questions People ask about ABS 3D Printing service

What is ABS?

Acrylonitrile Butadiene Styrene (ABS) is an opaque thermoplastic and amorphous polymer. It is a non-crystalline plastic that can be heated to its melting point, cooled, set, and then reheated without notable degradation. ABS is used for various products due to its low cost, durability, and strength. ABS thermoplastics are easy to mold and produce study products. The process must be enclosed due to toxic fumes, although the material has no known carcinogens.

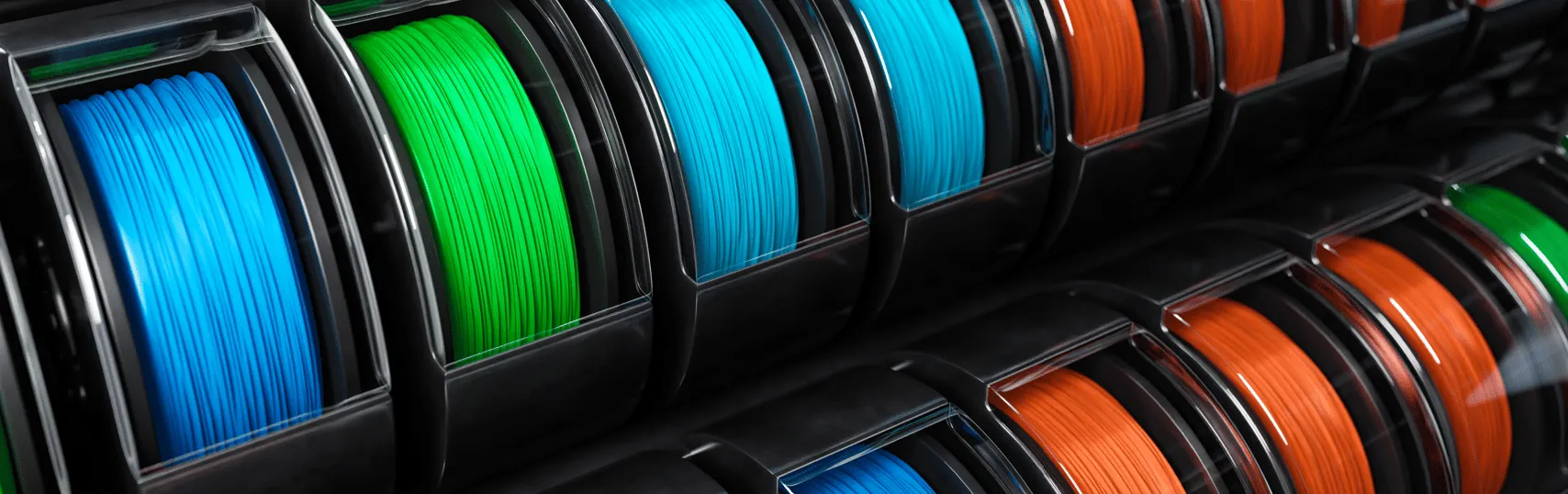

ABS is preferred for 3D printing and injection molding operations and was vital in the rapid rise of 3D printing technology. The material is relatively inexpensive and comes in a wide range of colors. It has excellent acoustic and thermal insulation properties and strong impact resistance. ABS is widely used across several sectors of the economy, including automotive, agriculture, construction, defense, electronics, medical, pharmaceutical, and food and beverage. Some products manufactured with ABS include automotive parts, toys, power tool housings, packaging, household appliances, and electronics.

What is FDM ABS 3D Printing?

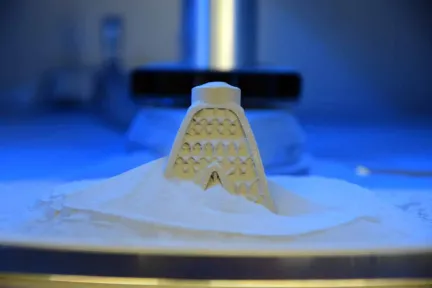

Fused Deposit Modeling (FDM) is an additive manufacturing 3D printing process frequently paired with Acrylonitrile Butadiene Styrene (ABS), a popular thermoplastic used in FDM 3D printing. FDM is cheaper than another popular additive manufacturing process, selective laser sintering (SLS) 3D printing. FDM printing is inexpensive and fast, producing tough and sturdy products.

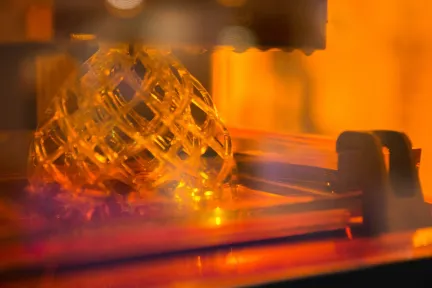

FDM ABS 3D printing uses spool-fed ABS filament extruded through a printing nozzle that heats and then applies the material for printing. The print head either moves or the base is moved for selected placement of the material is built one layer at a time. Printing is performed in an enclosed environment to contain fumes and prevent possible product warpage. Printed supports reinforce the product during the printing operation. Once printing is completed, the supports are removed, and the part is ready for subsequent processes.

The FDM printing systems are capable of reasonable product tolerances (+/-0.02”), producing a semi-smooth finish that can easily be machined, glued, sanded, plated, or painted. Some printers have multiple extrusion systems that can print two or more materials, including a variety of filament colors, into one product.

There are five basic types of FDM printers. The difference is based on the positioning articulation and how the print head or print bed moves to print the parts.

- Cartesian FDM Printer—Three orthogonal axes—X, Y, and Z are used to determine the correct positions and direction of the print head. This inexpensive entry-level 3D printer is the most common type of FDM printing.

- Polar 3D FDM Printers — The positioning of Polar 3D FDM printers is determined by the angle and length. The print bed rotates and moves simultaneously, with the extruder moving up and down. These printers are ideal for cylindrical objects.

- Delta FDM Printers—Similar to the Cartesian FDM printer, the Delta FDM printer has an immovable circular print bed and prints much faster.

- FDM Printing with Robotic Arms — A relatively new concept in printing, the print head is mounted on the end of a robotic arm that moves to construct the product. This printing method is best for complex structures.

- Hybrid 3D Printers—These expensive printers use both additive and subtractive manufacturing to manufacture the product. It combines a 3D Printer with a 5-axis CNC milling machine.

Application of FDM ABS 3D Printing

Flexible and inexpensive to manufacture products, FDM ABS 3D printing provides robust and lightweight proof-of-concept models and rapid prototyping. This ABS printing process is also used for food packaging, jigs, fixtures, and product tooling. Products can be produced with a tremendous variety of color filaments. FDM ABS 3D printed products can also be machined, glued, sanded, and painted, painted. ABS is frequently used in chrome plating applications since it is easy to plate. The products provide a consistently smooth surface finish.

Benefits of FDM ABS 3D Printing

FDM ABS printed parts are easy to manufacture and are a cost-effective process for prototyping and manufacturing certain end-use products. This printing method is fast, accurate, and flexible, with various filaments and colors available. Parts are inexpensive to produce, lightweight, sturdy, and impact resistant.

Products are resistant to corrosion and can be ultraviolet-resistant with an additional coating. ABS material has no known carcinogens, so it is safe for many applications. FDM ABS printing is a popular process with new materials and colors being produced regularly. Change-overs are quick, and production parts can quickly be manufactured on demand. ABS products are thermoplastics, which can be melted and reused in recycling. No tooling is required to aid the typical FDN ABS printing process.

Discover our other manufacturing services

Get multiple quotes for your parts in seconds