3D Printing Service USA

3D printing services in the USA are setting the benchmark for the Additive manufacturing industry. 3D printing is used for a variety of new and innovative applications. Learn more now!

SECURE PAYMENTS

Via payment card or purchase order

PROTECTED IP

Your data is confidential and secure with us. Use your own Non Disclosure Agreement

INSTANT QUOTE

For 3D Printing and CNC Machining, get quote in few seconds.

Your US 3D printing service

3D printing service with 3DEXPERIENCE Make

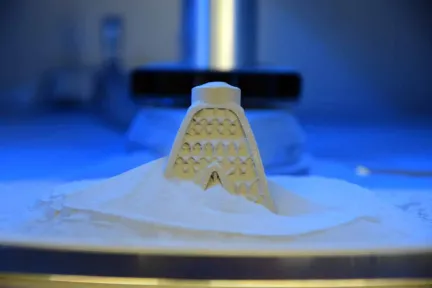

3DEXPERIENCE Make is an On-Demand Manufacturing platform, which connects designers or engineers with industrial 3D Printing service providers. Our service providers are mostly based in North America (the United States and Canada) and Europe (United Kingdom, France, Netherlands, Germany, etc.). 3D Printing service is today mostly used for Mockup or Prototyping (technical or presentation), but some of our partners can help you on small series, or even large series.

Thanks to our powerful algorithm, you can get a quote in seconds for your 3D Printing project from dozens of 3D Printing service providers.

Our 3D Printing service is handling projects in various industries such as Aerospace & Defense, Business Services, Construction, Consumer goods & retail, Energy & Materials, High-Tech, Home & Lifestyle, Industrial Equipment, Life Sciences & Healthcare, Marine & offshore, or Transportation & Mobility.

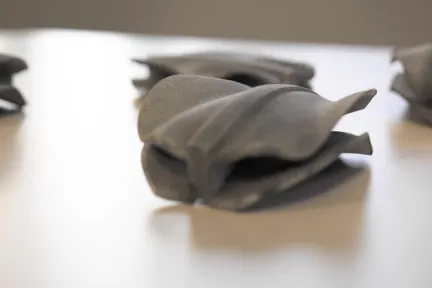

Our network of 3D Printing service providers offers hundreds of materials for your project, Plastic (PA12, ABS, PLA, PET, etc.), Metal (Stainless steel, 316, Aluminum, Titane, etc.), Ceramic, Wax, Sand or Composite (PA Glass, PA aluminum, ABS Carbon fiber, etc.).

Our online 3D printing services

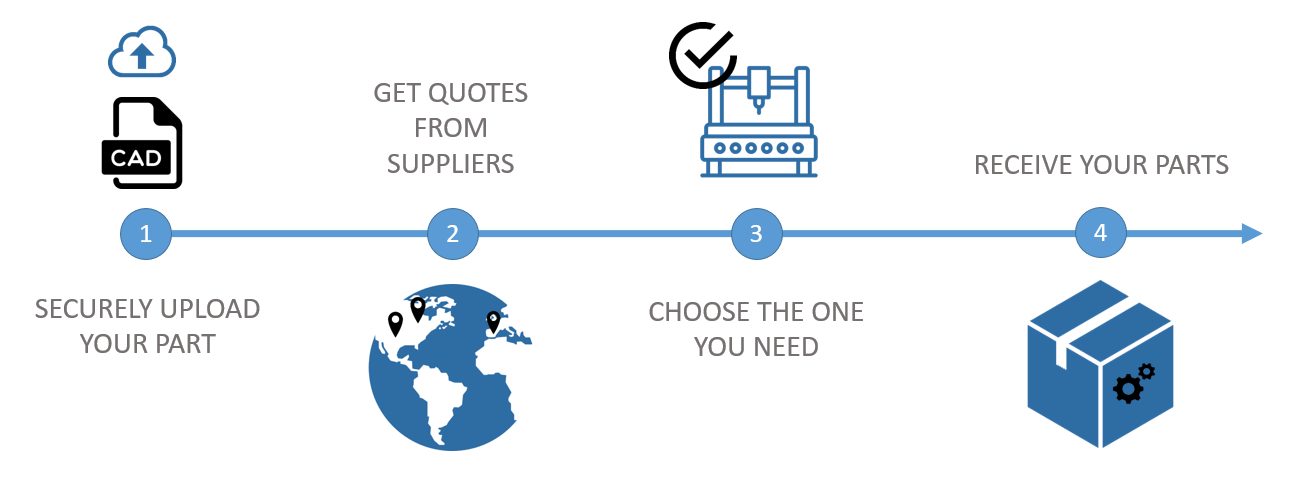

Online 3D Printing service: how does it work?

3D printing location in the US

3D printing Houston

3D printing Austin

3D printing Los Angeles

3D printing Seattle

3D printing Chicago

3D printing New York

More information about 3D Printing in the USA

The 3D printing industry is an integral component of the additive manufacturing market. In the 3D printing process, the material is added and fused, layer by layer, to create a product based on a 3D drawing. 3D printing is used in a wide variety of industries, including aerospace, automotive, healthcare, and consumer goods. The 3D printing market in the USA is rapidly growing, outpacing the United States economy, and is expected to continue to grow quickly over the next decade.

How Big is the 3D Printing Industry in the USA?

The market size of the 3D printer manufacturing industry in the USA has grown 19.5% per year on average between 2017 and 2022. In 2021, the United States became the country with the largest number of 3D printing patents. The United States is approximately 24.3% of the global market, which was $16.75 billion in 2022, and the United States' compound annual growth rate for 3D printing in 2022 is tracking at 28.1%. The worldwide 3D printing economy is projected to grow to $75.17 billion by 2030, with the United States continuing to lead all other countries.

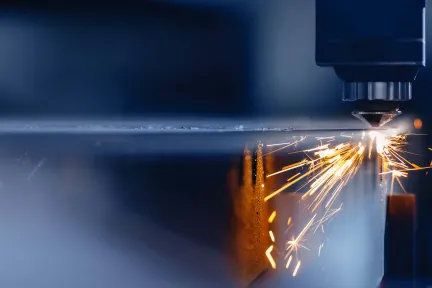

The aggressive research & development in the 3D printing market and the growing demand for prototyping applications should continue the market growth and leadership in innovation. The key markets include healthcare, automotive, aerospace, and defense, thanks partly to the rapid development of new and specialized materials for a rising number of applications. The decreased prices in printers have also fueled the rapid growth in the 3D printing industry in the United States. With this, expertise has also proliferated. The 3D printing technology is quickly increasing with newer fused deposition modeling methods. These methods have enhanced the development and use of assorted materials, which has furthered widespread adoption across all industries.

Drivers for growth in the United States 3D printing industry include the significant demand in the aerospace industry. The Aerospace and military sectors have embraced 3D printing technology, and it is expected to continue to grow for the foreseeable future. More than 2.2 million units of 3D printers were shipped worldwide in 2021. Shipments are expected to reach 21.5 million units by 2030.

The penchant for customizable gifts is another market segment ripe for 3D printing technology. This includes monograms, pictures, names, initials, and other personalized items. The current market is $22 billion, and 3D printing is expected to expand and consume some of the existing sales. Other areas include custom apparel design and jewelry manufacturing.

What are the top trends of the U.S. 3d printing industry?

The United States 3D printing market has approximately 60% industrial printers with around 40% desktop models. This indicates that small businesses are catching on to 3D printing technology. The United States market is equally divided, with approximately 40% hardware, 30% software, and 30% services.

The 3D printing industry's dynamic technological advances in machines and materials continue to allow an ever-growing number of applications. These advancements have led to a price reduction for the technology. This makes the technology more likely to be adopted by downstream industries and customers.

The industry trends in the United States 3D printing sector include:

- Increased Adoption of 3D Printing: The U.S. 3D printing industry is seeing increased adoption of 3D printing for various applications, including prototyping, manufacturing, and medical applications.

- Advancement in Technology: 3D printing technology is rapidly evolving, with new materials, capabilities, and applications under constant improvement.

- Improved Quality of 3D Printed Parts: With advances in 3D printing technology, 3D printed parts are becoming increasingly more robust and reliable, with improved dimensional accuracy, strength, and surface finish.

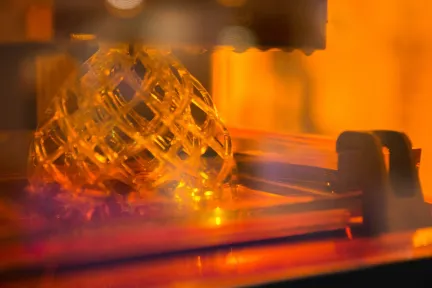

- Growing Use of Plastics and Resins: Plastics and resins are becoming increasingly popular materials for 3D printing due to their affordability, availability, and versatility.

- Use of Metal-Based 3D Printing: Metal-based 3D printing is becoming more popular in the United States thanks to its ability to produce more robust and durable parts than traditional manufacturing methods.

- Focus on Automation and Additive Manufacturing: Automation is becoming an increasingly important part of the 3D printing industry, as it allows for faster and more efficient production of 3D printed parts. Additive manufacturing is also gaining traction, as it allows for the creation of complex shapes that can't be achieved with traditional manufacturing techniques.

- Embracing Open Source Technology: Open-source 3D printing technology is becoming increasingly popular in the United States and the more progressive 3D economies worldwide. Open Source technology allows businesses to access high-quality 3D printing technology at a fragment of the cost.

- Growing Use of Digital Manufacturing: Digital manufacturing is becoming more popular as companies look for ways to reduce production costs and streamline operations. 3D printing can be used to create digital models of products, which can then be used to create physical products.

- 3D Printing in Fashion and Apparel: Escalating demand for 3D printing in apparel design.

- Increased Use in the Medical Industry: 3D printing is used in the medical industry to create prosthetics, implants, and other medical devices. 3D printing is already creating tailored prosthetics and tooth implants. It is anticipated that technology will allow the replication of human organs with a 3D-printed organ base using stem cells to grow tissue.

- Growing Use in Manufacturing: 3D printing is used in manufacturing to produce custom and complex parts quickly and cost-effectively.

- Growing Use in Education: 3D printing is used in classrooms to help students better understand complex concepts and foster creative thinking.

- Expansion into New Markets: 3D printing is continually being explored in new markets, such as automotive, aerospace, and consumer products.

- Sustainable Solutions: As environmental concerns become increasingly important, businesses are looking towards sustainable solutions like 3D printing, which can reduce energy consumption and waste compared with traditional manufacturing methods.

Discover our other manufacturing services

Get multiple quotes for your parts in seconds