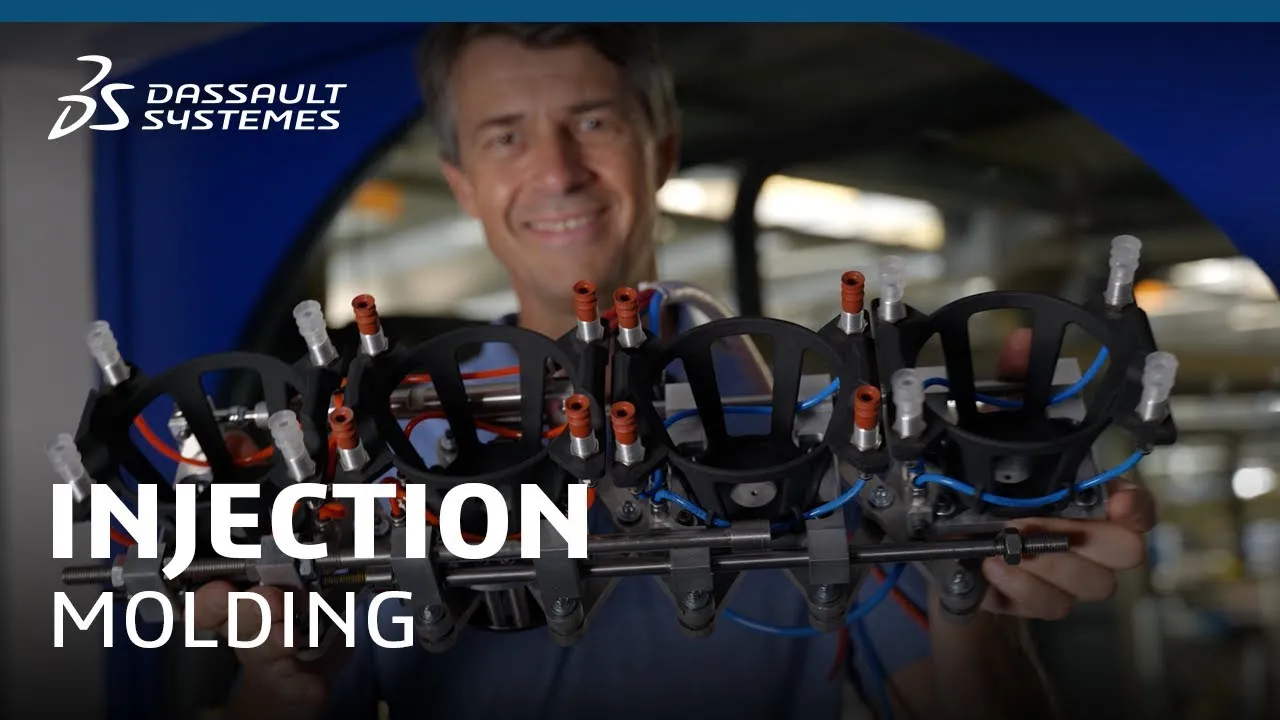

Video Injection Molding

Discover in video how the Injection Molding process works with 3DEXPERIENCE Make, the on-demand manufacturing, by Dassault Systèmes and his partner Platex.

What is the injection molding?

Hello, today we’re here at Platex to discover the industrial injection molding manufacturing process.

Ready to be amazed!? Let’s find out how manufacturers transform almost transparent material and add color through an industrial process, producing a ready-to-use two-color, two-material part within seconds.

How does injection molding work?

Injection molding manufacturing is an industrial process used to manufacture large volumes of plastic parts.

The manufacturing process is split into different phases.

First off is the mold design phase, which is managed by a design office working alongside product designers and industrial teams. Once designed, the mold is placed in a machine called an injection molding press. Look, here’s one. This press is connected to the material arriving upstream, which is heated and gradually supplied to your mold.

Using a high-powered tool, we inject the molten material into the mold to create the piece’s shape. We then quickly cool the piece so that it hardens. Next, we eject the piece and start the process over. This is what we call ‘injection molding.’

What are the limitations of injection molding?

Injection molding isn’t without its drawbacks. As you’ve just seen, it’s a large-scale industrial process requiring a lot of machinery and equipment. But crucially, it relies on an essential element: the mold. The design and manufacture of this mold involve deadlines and fixed costs that need to be absorbed by the production of large volumes of parts. Moreover, not all parts can be produced. Injection molding has specific industrial limitations which you must consider in the upstream design phase. One final constraint: not all shapes can be produced. This is why you need to work closely with your design and industry teams to get the balance right between functional expectations and production capabilities.

What are the advantages of Injection Molding?

Injection is a mature and effective industrial process with multiple advantages. First, there’s its large-scale production potential. Second, its balanced use of materials. Third, its manufacturing cost per unit price. Injection molding delivers on competitiveness and performance, making it an excellent solution for mass production of series of plastic parts.

What are the usages in the industry of injection molding?

Injection has many uses. First of all, the fast-moving consumer goods sector requires multiple plastic items. Think of the mouse next to your computer. It’s manufactured using several parts from the injection molding process. Injection is also used in industries such as the automotive industry and for decor and interior design, both of which use plastic parts.

What are the differences between Injection molding vs 3D Printing?

At this point, you want to know the difference between injection molding and additive manufacturing (3D Printing) in terms of use. They’re two complementary industrial processes. Additive manufacturing lets you define a prototype upstream, and potentially manufacture a pre-series before wide-scale injection launch. Conversely, in some scenarios, albeit with certain limitations, you can manufacture molds using additive molding and use them on injection molding machines. Lastly, additive manufacturing (3D Printing) can create complex and invaluable tools to optimize the injection production chain.

Get multiple quotes for your parts in seconds