Video 3D Printing Multi Jet Fusion

Discover in video how the 3D Printing process Multi Jet Fusion (MJF) works with 3DEXPERIENCE Make, the on-demand manufacturing, by Dassault Systèmes and his partner Sculpteo.

Video: What is Multi Jet Fusion MJF?

Hello, today we are at Sculpteo and we are going to talk about the MJF manufacturing process from HP.

MJF technology standing for Mulitjet Fusion is an additive manufacturing process developed by HP. This process is at the crossroads of 3 other processes, powder sintering, material jet and binder jet. It enables us to manufacture parts in several types of plastic, sometimes in color and very quickly.

How does Multi Jet Fusion MJF work?

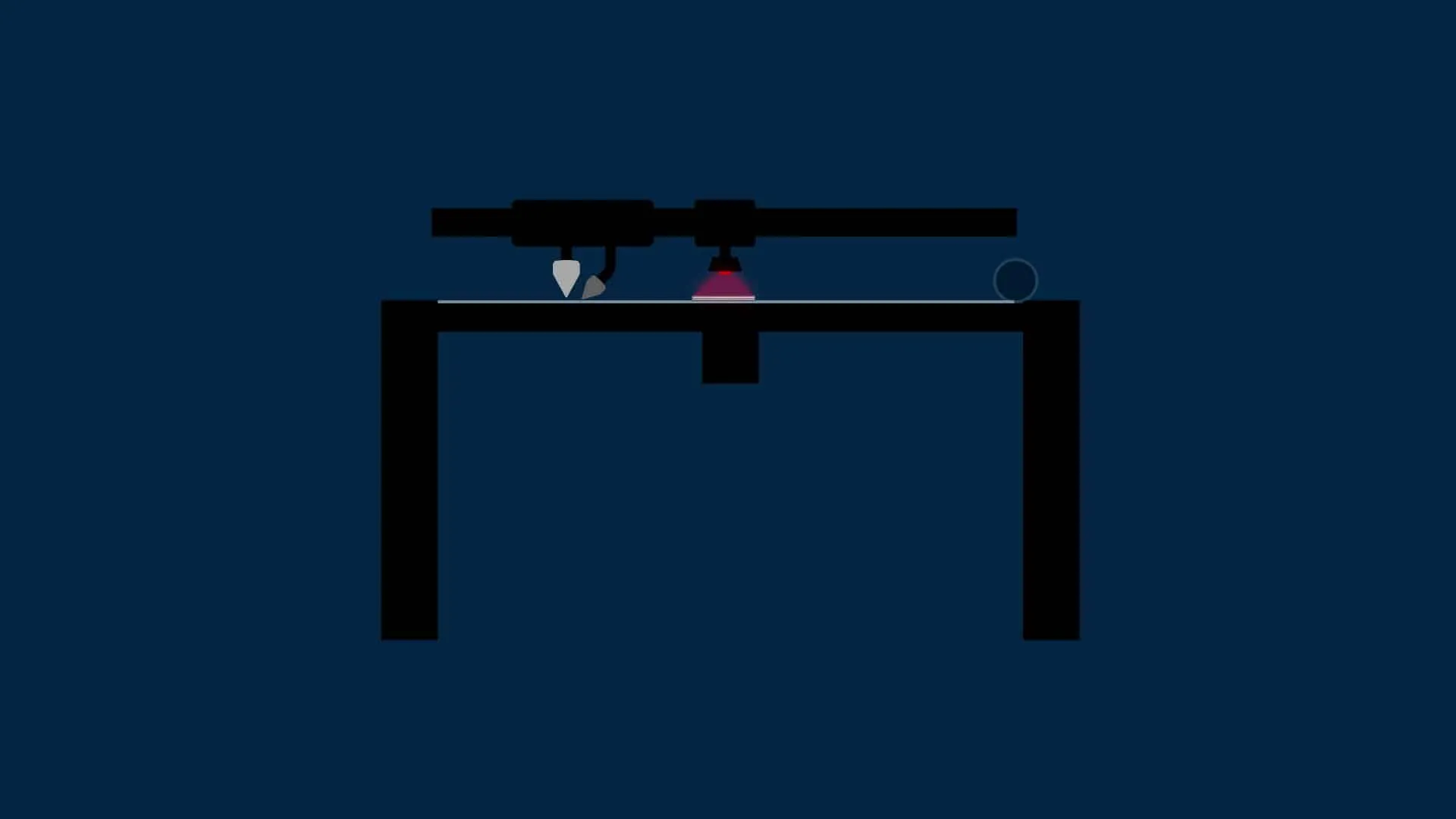

In concrete terms, how does it work? As with the SLS process, we have a printing platform on which we spread a thin layer of powdery material.

We spray two agents, a binding agent and a detailing agent on this layer of material. In concrete terms, black ink and white ink are contained here and will be sprayed on this layer, thus.

Once the material layer is sprayed, fusion lamps are used to heat the powder which enables two things.

- First, the powder that has been sprayed by the binding agent will solidify to obtain a layer of material.

- Second, the powder that has been sprayed by the detailing agent will mark the separation with the finished object.

- After that, the platform goes down a notch. A new layer of powder material is added, which will be treated in the same way as the first.

- And so on, layer after layer, until we have our finished object in its powder cake form.

What are the advantages and limitations of Multi Jet Fusion MJF?

In terms of benefits, MJF technology enables rapid mass production of high-quality plastic parts, in color if required. It is also good value for money and generates very little waste, thanks to the post-processing stations which enable the recovery of excess powder.

In terms of drawbacks, we can mention two main ones.

- The first is the limited choice of materials which are currently available as presented, marketed only by HP.

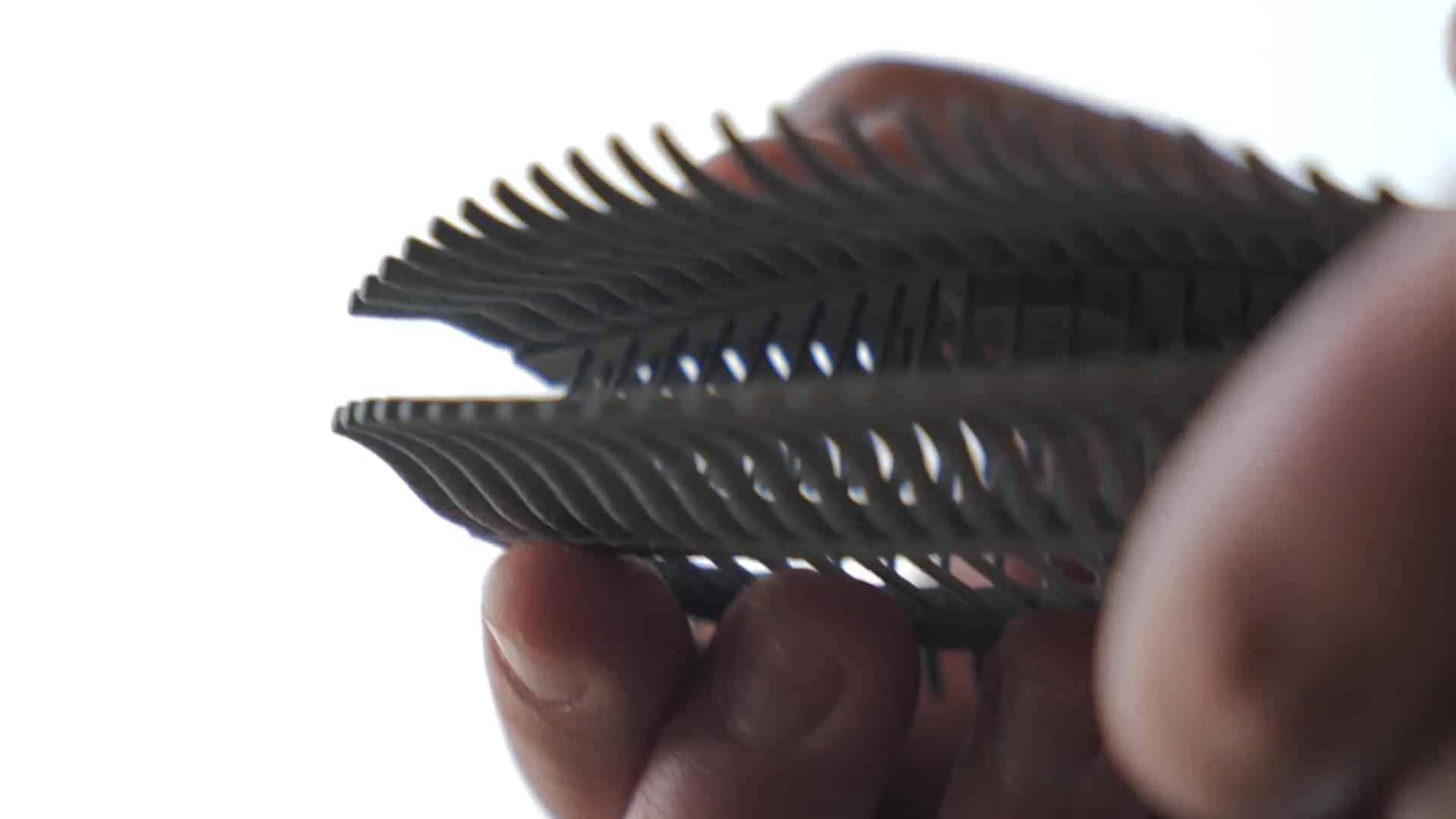

- The second relates to the surface finish which is rougher than stereolithography and material jetting.

What are the applications of Multi Jet Fusion MJF?

In terms of usage, MJF technology enables the production of parts that are perfectly suited for direct use in an end-use application, whether it is for small or medium series, rapid prototyping, or as an intermediate process for injection molding.

This technology is being adopted by more and more industries. These include the automotive and aerospace industries and the luxury goods industry, among others.

Get multiple quotes for your parts in seconds