Casting

Discover what is the manufacturing molding process Casting and its usage in the industry.

Introduction to Casting

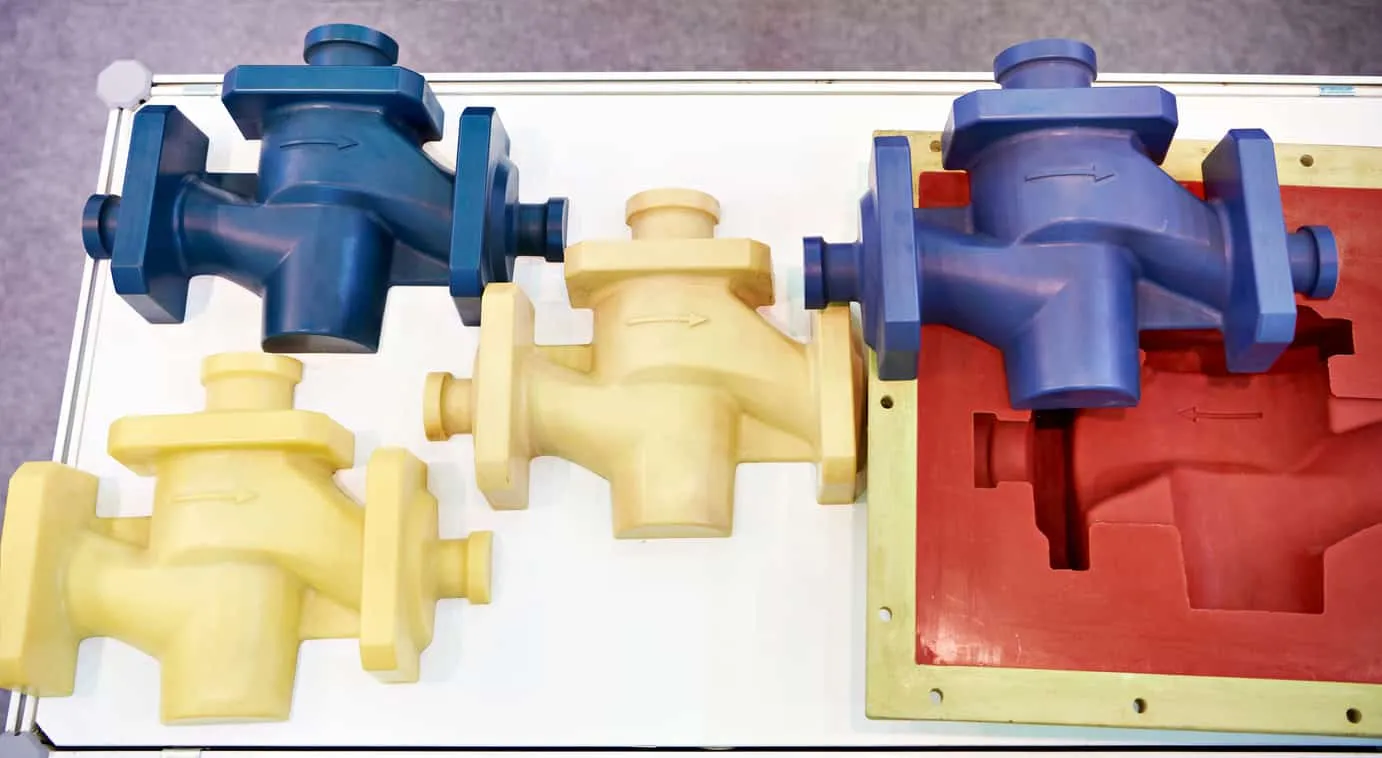

Casting is a 6,000year-old molding process that involves filling a liquid material into a mold of the desired shape. The liquid goes on to gradually cool and solidify. The solidified part is called casting. It is either ejected or broken out of the mold to finalize the process. Typically, the usage of metals or cold setting materials such as epoxy, concrete, plaster, or clay are common in casting. Casting is the preferred process for producing complex shapes that would otherwise be too difficult or costly to make through other methods. A copper casted frog is the oldest living proof that our ancestors used intricate casting patterns as early as 3200 BC.

What are the main types of casting?

The two main types of casting are metal and non-metal (such as plaster, concrete, or resin). Metal casting involves the heating of a metal into its liquid state and sequentially pouring the liquid into a mold. The mold and metal are allowed to cool until the liquid metal solidifies, at which point the casting is recovered from the mold. Plaster, concrete, or resin casting typically makes use of single-use disposable molds or multi-use molds made of small, rigid pieces such as latex rubber. The operator can apply topical treatments to the surface of plaster or concrete when the surface is flat or lacks transparency. Manufacturers can also use it to give the appearance of metal or stone. The construction of sinks, countertops, and shower stalls need resin. Adding powdered stone and different colors can provide a near-realistic imitation of natural marble or travertine.

Fettling is the process of cutting, grinding, shaving, or sanding away unwanted irregularities caused by seams and imperfections in the molds. Today, industry has adopted more and more the integration of robotics to perform some fettling. However, “fettlers” have historically carried out this grueling work manually, often with risks for repercussions to their health.

One way to save costs throughout the entire casting manufacturing phase is to apply casting process simulation software such as AutoCAST and MAGMa; this simulation uses numerical methods to calculate quality, solidification, and cooling, and provides a measurable prediction of the mechanical properties, thermal stresses, and distortion. It is the most valuable innovation in casting technology in 50 years.

Get multiple quotes for your parts in seconds