Binder Jetting

Discover how the manufacturing 3D Printing process Binder Jetting, also known as BJ, works.

Introduction to Binder Jetting—BJ

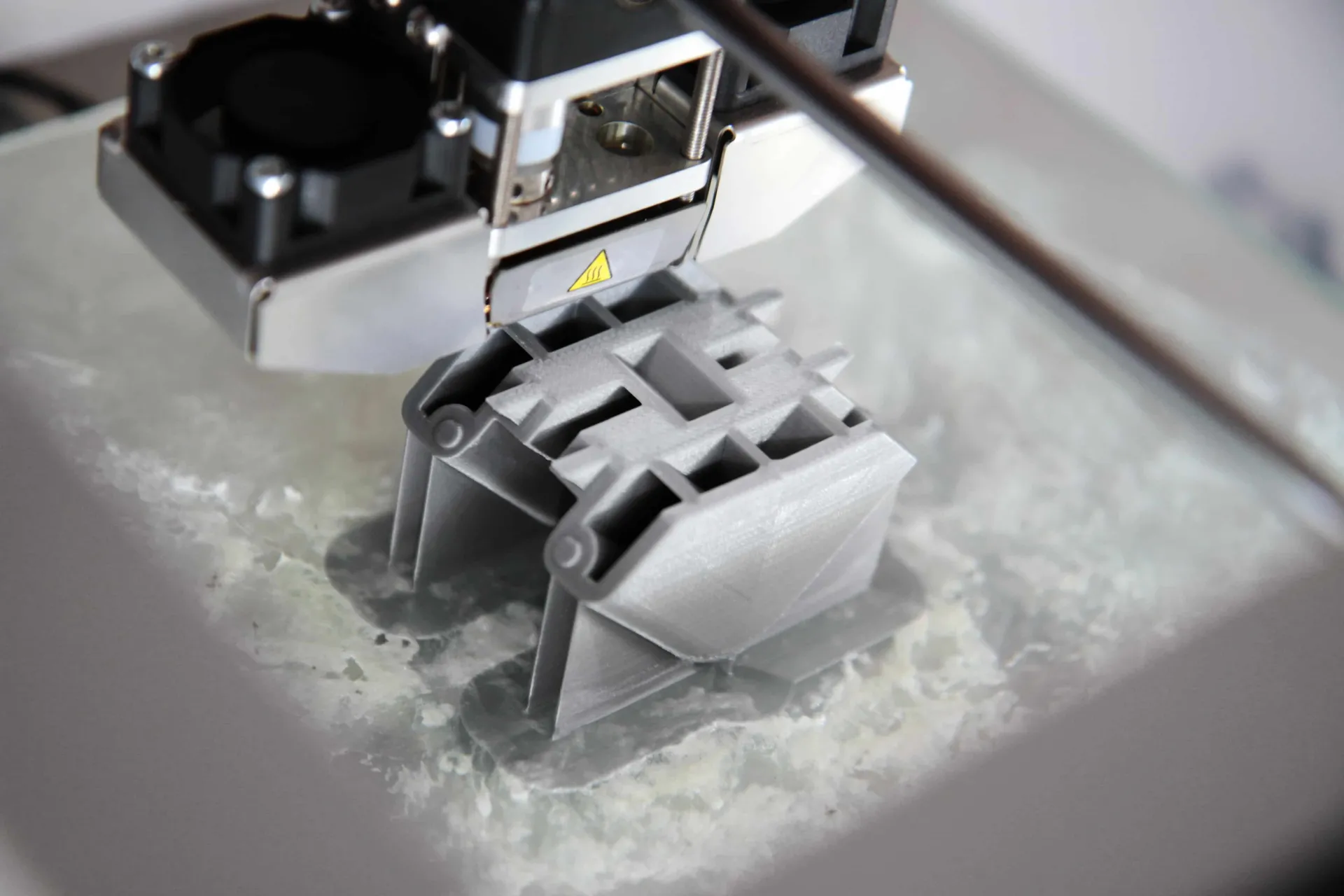

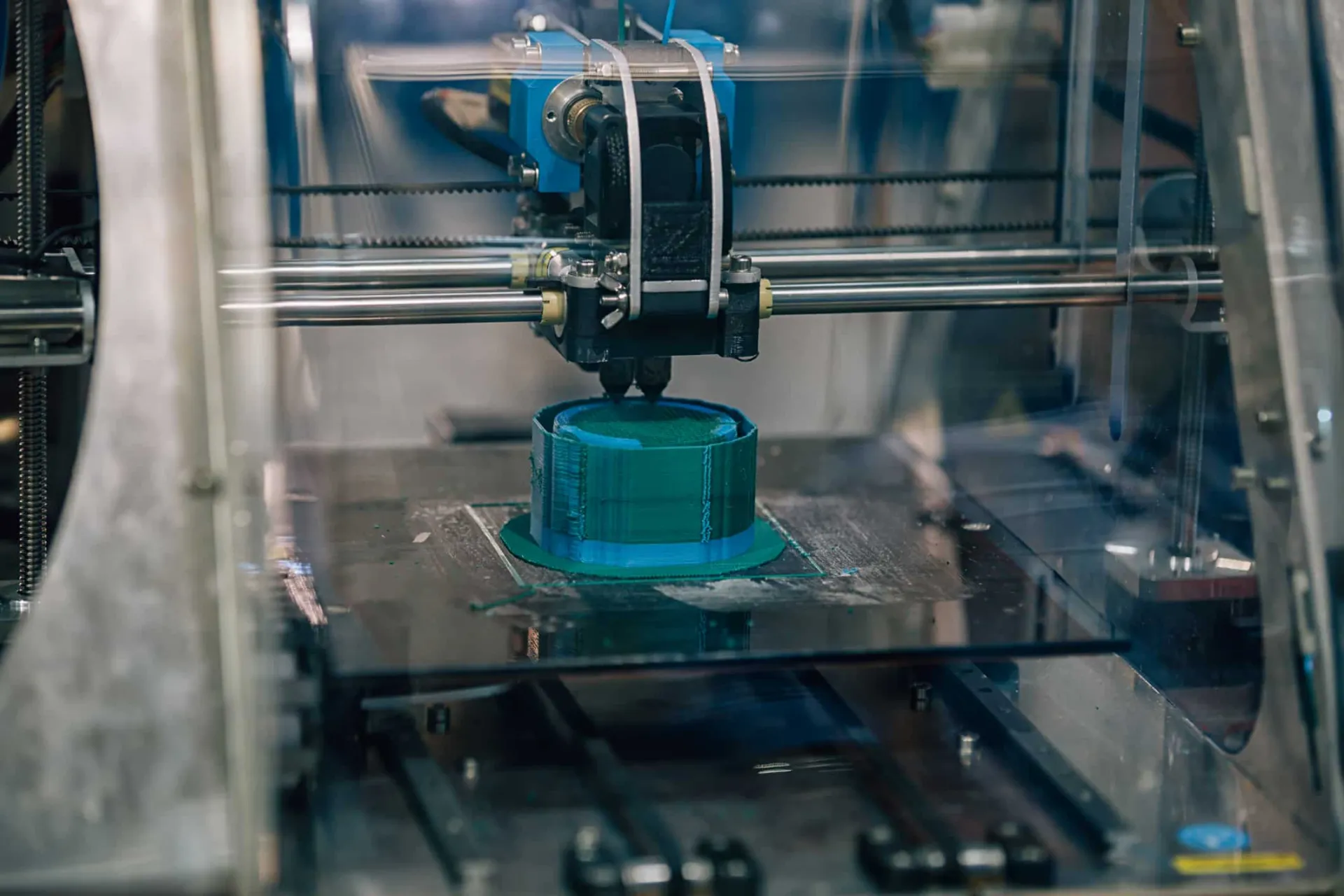

The binder jetting 3D printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. The powdered materials are ceramic-based (for example, glass or gypsum) or metal (for example, stainless steel).

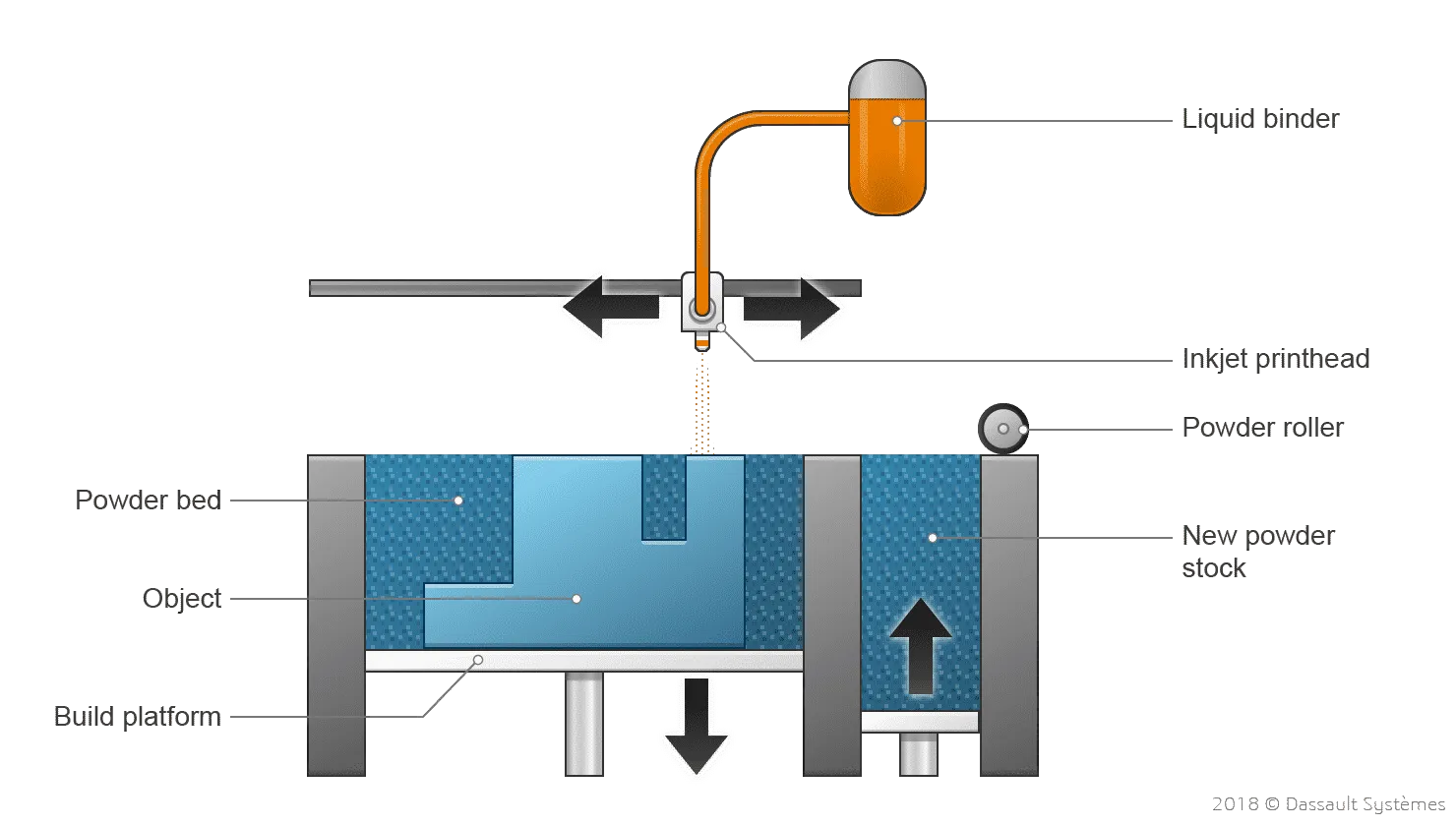

During the binder jetting 3D printing process, the 3D print head moves over the build platform depositing binder droplets, similarly printing each layer to 2D printers that print ink on paper. When a layer is complete, the powder bed moves downwards, and the printer spreads a new layer of powder onto the build area. The process goes on layer by layer until all parts are complete. After printing, the parts are in a green, or unfinished, state and require additional post-processing before they are ready to use. Often the operator adds an infiltrate substance to improve the mechanical properties of the parts. The infiltrate substance is usually a cyanoacrylate adhesive (in the case of ceramics) or bronze (in the case of metals). Another strategy is to put the workpiece inside an oven in its green state to achieve a sintering of the grains of matter. Interestingly, the term 3D printing originally referred to a process that deposited a binder material onto a powder bed with an inkjet printer-like heads layer by layer.

The binder jetting 3D printing process encompasses several techniques honed by different manufacturers. The most famous for the general public being:

ColorJet Printing (CPJ) by 3D Systems. ColorJet Printing is a trademark of the company ZCorp, now a 3D Systems company. ColorJet Printing 3D prints are fully colored. The final parts resemble sandstone and exhibit a somewhat porous surface. The sandstone material is inkjet colored and glued together during the 3D printing process. At the end of the 3D printing, an infiltration is necessary to solidify and bond the part. Hundreds of thousands of colors are available, almost the entire CMYK spectrum. The final prints are not intended for functional applications as they remain porous and must be kept away from humidity to avoid discoloration.

Binder Jetting and materials

The binder jetting 3D printing process can work with various materials, including metals, sands, and ceramics. Some materials, like sand, require no additional processing.

Binder jetting is excellent for applications that require good aesthetics and form, such as architectural models, packaging, toys, and figurines. It is generally not suited for functional applications due to the brittle nature of the parts.

Compared to Powder Bed Fusion (PBF) 3D printing techniques, the binder jetting method has the advantage of not employing heat during the build process, which prevents the creation of residual stresses in the parts.

Metal-based binder jetting parts have relatively good mechanical properties thanks to the infiltration process. They can be a functional component and have relatively good mechanical properties thanks to the infiltration process. They are also more cost-effective than SLM (Selective Laser Melting) or DMLS (Direct Metal Laser Sintering) metal parts but have poorer mechanical properties because the grains of materials do not entirely fuse together.

There are various types of 3D printing binder materials, each suited for a specific application. They can be listed in categories including furan binder (for sand casting applications), phenolic binder (for sand molds and cores), silicate binder (environmentally friendly, for sand molds and cores), and aqueous-based binder (for metals).

Get multiple quotes for your parts in seconds