MBSE for Defense Electronics

Secure acquisition of modular defense electronics through model-based collaboration and virtual twins — all powered by the 3DEXPERIENCE® platform.

Defense electronics are integral to national security, playing a critical role in virtually every military operation and program. Over the decades, connected electronic systems have evolved from mechanical to mechatronics, and now to sophisticated cyber systems, with military electronic components and software playing a bigger role in the path to success.

As global defense budgets rise and geopolitical pressures to sustain defense modernization intensify, a substantial share of defense spending is directed toward electronics. Key initiatives such as the Combined Joint All-Domain Command and Control (CJADC2), Future Combat Air System (FCAS) and High-Accuracy Detection and Exploitation System (HADES) highlight the growing importance of tactical communication systems and cutting-edge defense electronics. The Advanced Battlefield Management System (ABMS), similar to CJADC2, is seeing a double-digit growth in the mid-2030s as the technology matures.

Despite the clear need for modern defense electronics, OEMs face major challenges, especially in today’s increasingly worrisome threat environment. These challenges include:

High Integration Costs

Integrating and upgrading programs within a platform often results in significant budget overruns and delays.

Systems Complexity

Deploying new technologies across various weapon systems is highly complex, with interconnectivity being a critical success factor.

Supply Chain Volatility

Securing long-term availability of essential electronic components is both vexing and costly, disrupting production schedules.

Dassault Systèmes 3DEXPERIENCE platform addresses these challenges with a holistic approach to systems of systems from conception to manufacturing and operations. It integrates applications for governance, collaboration, design, manufacturing, sustainment and more — all enhanced by AI-driven capabilities and connected by a digital thread that ensures seamless data flow across all stages of the product lifecycle.

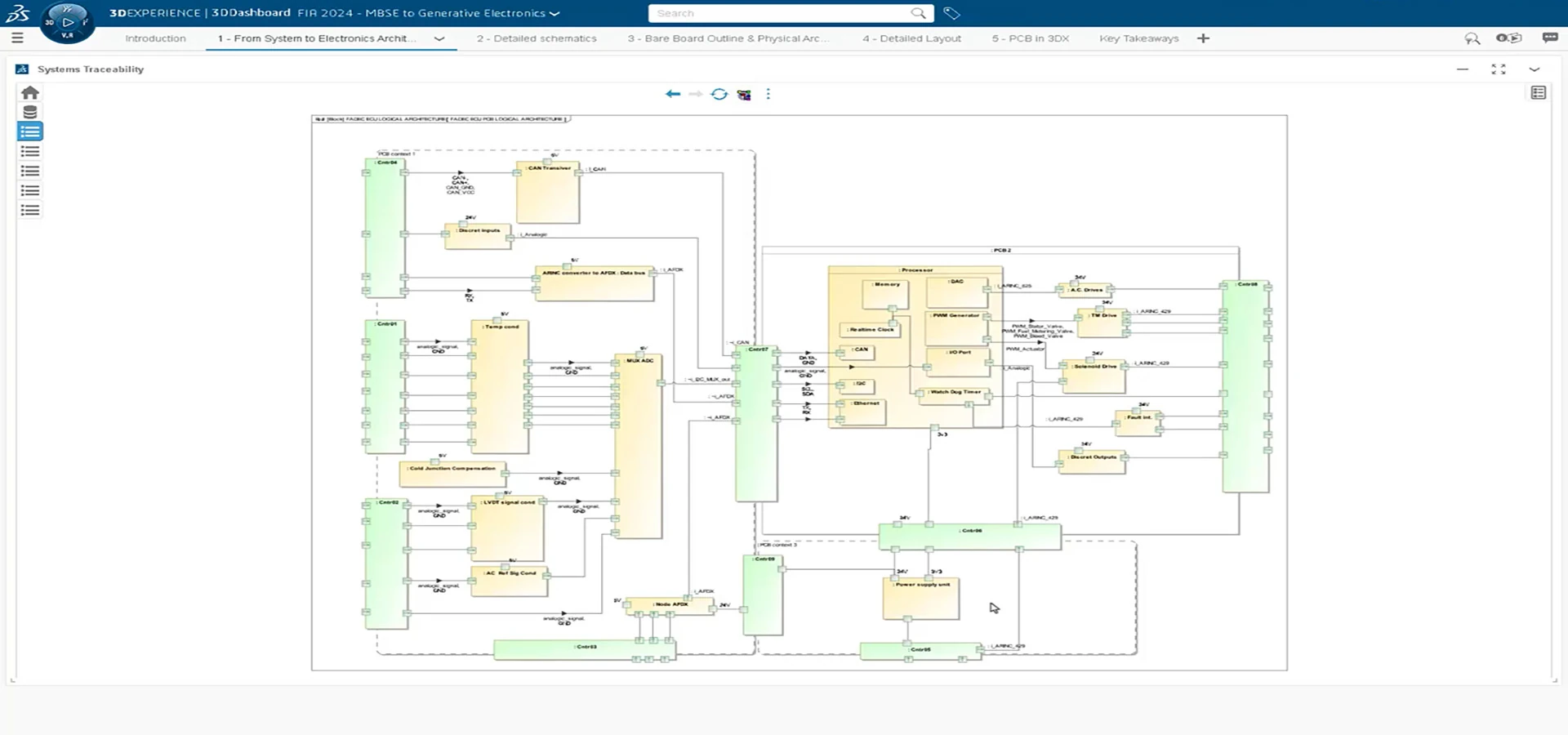

Additionally, the platform incorporates a unified modeling and simulation environment called MODSIM. MODSIM is more than just a simulation-driven design; it allows simulation to drive the entire product development process from start to finish. This unified experience supports key stages such as requirements and architecture definition, certification, product development and program management. It also facilitates design exploration, process automation, decision and change management and collaboration across the value network.

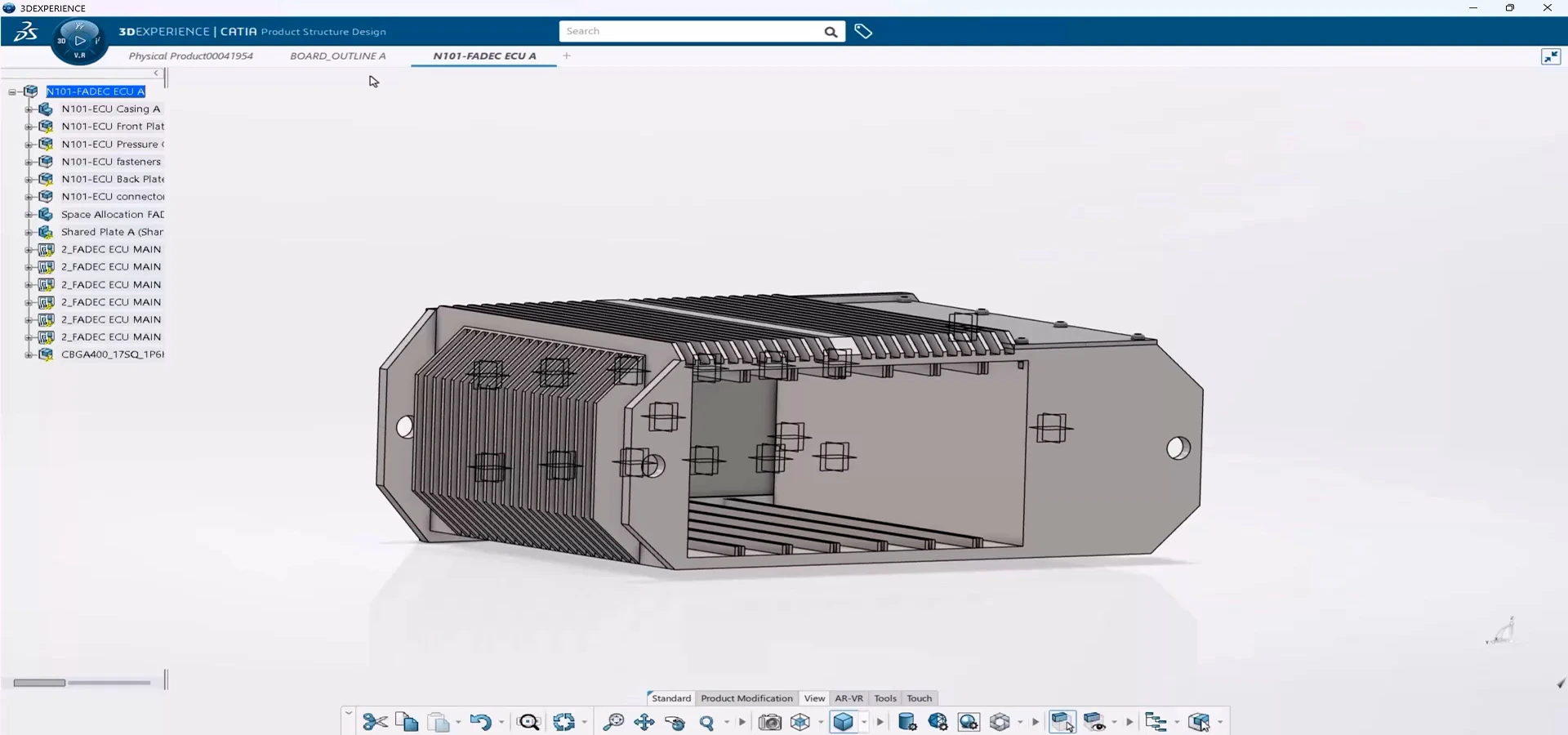

To tackle the rising complexity of defense electronics, the platform also enables a model-based electronics architecture approach — a subset of systems architecture focusing specifically on the electronics portion of a defense system. By applying this methodology, manufacturers can ensure compliance with industry standards while fully realizing the benefits of model-based systems engineering (MBSE) for defense electronics.

MBSE for Unmatched Defense Electronics Systems

Learn how defense manufacturers can optimize complex cyber systems development with the 3DEXPERIENCE platform.

MBSE for Modular Defense Electronics — From Design to Deployment

Collectively, the suite of applications and the MODSIM environment on the 3DEXPERIENCE platform are integral to a digitally-enabled MBSE approach. Recognizing its significant business benefits, the U.S. Department of Defense, along with the broader aerospace and defense industry, is strongly encouraging OEMs to adopt MBSE across all major programs to reduce execution risks and manage increasing systems complexity. Understanding the operational and technical strengths of MBSE reveals why it is emerging as a cornerstone for modern defense electronics programs. Here’s how it delivers on that promise.

Develop Disruptive and Reliable Electronics Solution in Record Time

Eliminate technical risks early with virtual twins. Fully model, simulate and optimize every aspect of a defense electronics system before committing to prototypes — achieving up to 30% fewer physical prototypes while compressing time to market.

Seamless Multidisciplinary Collaboration, First-Time-Right Electronic Design

Streamline ECAD-MCAD collaboration to achieve AI-driven generative electronics powered by the 3DEXPERIENCE platform, securing first-time-right designs. Validate electrical-software interactions early and minimize errors without costly rework.

Built for Modularity, Full Consistency and Traceability

Manage high-performance electronics with full lifecycle traceability using an MBSE approach. Drive modular development from initial requirements to final validation, fully compliant with the Modular Open Systems Approach (MOSA) — unlocking interoperability at its finest.

The Partnership Driving Defense Electronics Win

Discover how Dassault Systèmes' partnership with Cadence creates an end-to-end collaborative environment for complex electronic systems — keeping national security systems mission-ready. See the impact in action.

Engineering Complex Defense Systems on a Single Source of Truth

As new mission needs intensify across multidomain operations, defense electronics will play an even more critical role — one that demands that equipment and software suppliers deliver the most capable systems on time and within budget. As former U.S. Secretary of Defense Mark Esper told a professional audience at the Center for Strategic and International Studies: “The future of warfare will be defined by those who can harness and integrate advanced technologies, including sophisticated defense electronics. Our investment in these [and other] areas is crucial for maintaining strategic advantage and deterring aggression.”

Dassault Systèmes’s 3DEXPERIENCE platform, with its suite of digitally-enabled capabilities, is more than just an option for how the industry could help its national security partners answer the call of duty in the best possible way. It’s a proven set of integrated digital solutions that has enabled defense electronics providers to achieve quantifiable results in meeting the demanding expectations of their customers.

With this platform, the foundation for next-generation defense electronics is set. Ready to drive it forward?

Model-Based Systems Engineering for Defense Electronics: FAQ

Discover More

Explore our Industry Solution Experiences

Learn how to deliver on economic, environmental and social promises: