On-Demand manufacturing

On-Demand manufacturing across all processes. Upload your design, get your instant quote, choose your manufacturer and receive your part.

SECURE PAYMENTS

Via payment card or purchase order

PROTECTED IP

Your data is confidential and secure with us. Use your own Non Disclosure Agreement

INSTANT QUOTE

For 3D Printing and CNC Machining, get quote in few seconds.

On-demand manufacturing with 3DEXPERIENCE Make

3DEXPERIENCE Make is an online on-demand manufacturing platform operated by Dassault Systèmes. It connects the industrial ecosystem of Designers, Engineers, Buyers, and Production planners with industrial manufacturing service providers such as Xometry, Sculpteo, American Additive, Get It Made, Any-Shape, TH Industries, and a lot more.

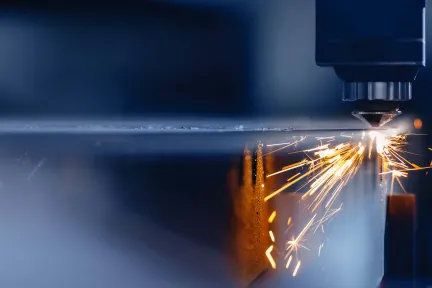

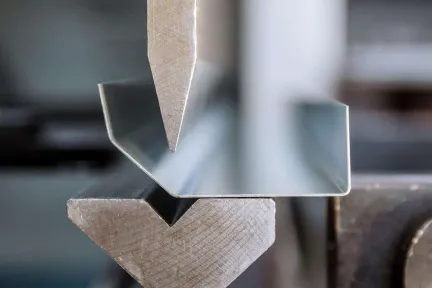

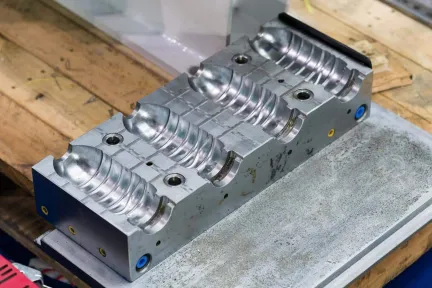

You can be confident to find the best partner based on your project requirement. Available across all processes such as 3D Printing, CNC Machining, Injection Molding, Cutting, Sheet Metal.

3DEXPERIENCE Make allows you to choose the perfect material for your parts such as ABS, PA, and metal materials.

3DEXPERIENCE Make, the on-demand manufacturing platform, is also directly accessible via an Add-in from SOLIDWORKS, CATIA, Draftsight, and eDrawings which allows a faster design workflow for a better end-to-end experience.

Discover SOLIDWORKS 3DEXPERIENCE for Makers

What are the processes?

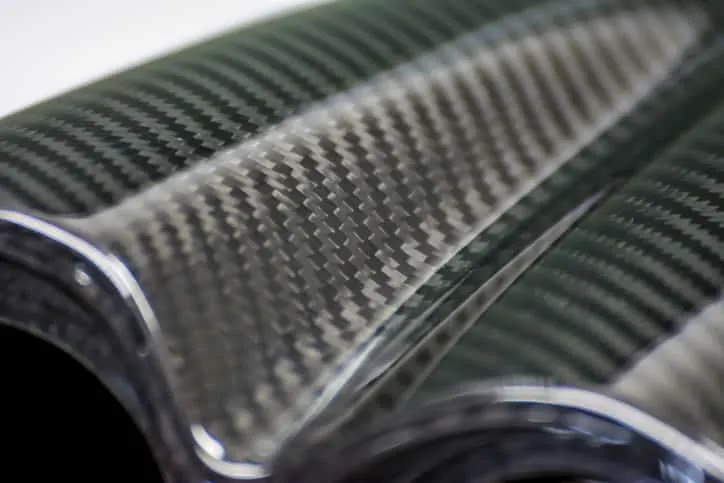

Which materials on 3DEXPERIENCE Make?

Plastics

Metal

Composite

Discover how 3DEXPERIENCE Make can answer your on-demand manufacturing needs

The 3DEXPERIENCE platform, operated by Dassault Systèmes, is a game-changer for business and innovation, providing software and collaboration tools for every stage of the product development process.

One such tool is 3DEXPERIENCE Make, an online on-demand manufacturing platform that connects buyers with an industrial ecosystem of more than 100 qualified service providers.

This one-stop-shop for on-demand manufacturing processes offers 3D printing, CNC machining, injection molding, cutting and sheet metal. Using a search tool based on your project specifications, you can be confident to find the perfect partner, process and material for your specific needs.

Tools for design, planning, testing, manufacturing and more ensure that you get your parts ordered, made and delivered in record time.

All it takes is four simple steps:

Upload your design

Optimize it live

Choose your manufacturer

Receive your custom parts

Check the video to learn more about On-demand manufacturing at 3DEXPERIENCE Make.

Advantages of on-demand manufacturing

TIME EFFICIENCIES

On-demand manufacturing streamlines and improves the interaction between a buyer and a supplier. Centralizing the entire process, providing a single point of contact and automating routine steps, such as with instant quoting, helps overcome the delays found in traditional supply chain management.

With the supply squeeze pushing up lead times, sometimes by several months, on-demand manufacturing enables products to be developed, made and delivered in a much shorter timeframe. This agility and scalability are vital if companies are to seize opportunities quickly and effectively, whenever and wherever they may arise.

COST SAVINGS

On-demand manufacturing removes the need to buy, store and manage spare inventory. This frees up money for more value-added activities such as marketing, recruiting, training, new tools and product development.

With companies focused on reducing costs while improving output, adopting an on-demand manufacturing model can be a profitable strategy.

PROCESS CONTROL

From ordering to final delivery, on-demand manufacturing provides live updates via the cloud. This makes it possible for buyers and suppliers to communicate and manage projects in real-time and with greater control.

These insights provide visibility into the status of a given project and make for effortless tracking, reporting and stock management. Clearer transparency also helps to identify areas of improvement and risk, and makes reacting when a problem does occur faster and more effective.

PRODUCT INNOVATION

Being able to quickly and affordably produce a single prototype or small sample batch provides the flexibility to test new ideas without needing to invest money in full-scale production.

As a result, the time and risks involved with new product development come down while the likelihood of it being successful goes up.

Drawbacks of on-demand manufacturing

PRODUCTION VOLUME

On-demand manufacturing is well suited for one-off customizations, low-volume such as that used in early prototyping and testing, and medium volume of between 50 and 100,000 units. For mass quantities, it may be best to select a manufacturer who specializes in traditional high-volume production.

SUPPLIER MANAGEMENT

Taking advantage of the efficiency and flexibility of on-demand manufacturing means surrendering control of the production process. As a result, you may not know the exact techniques, level of skill or technology used to fulfill your order.

This may result in a delay in learning about production or delivery issues, and then dealing with them.

QUALITY CONTROL

There are a growing number of on-demand manufacturing platforms available from both established global leaders and start-ups. How involved these platform owners are in overseeing quality standards varies.

Some are very involved in making sure standards are high across their ecosystem of manufacturing partners. Others take a more hands-off approach. As with any business arrangement, companies should fully research any potential partner before signing a contract.

RANGE OF SERVICES

Not all on-demand manufacturing platforms offer the same range and depth of services, so it’s important to understand your needs and then select the platform and partner best able to meet them.

On-demand manufacturing: How does it work?

Connect With Manufacturers Now

Upload your design. Browse our manufacturers. Get quotes and pick the one for your needs. Receive your parts.

3DEXPERIENCE Make means On-demand manufacturing made quick and easy but with the guarantee of Dassault Systemes qualified networks of manufacturers.

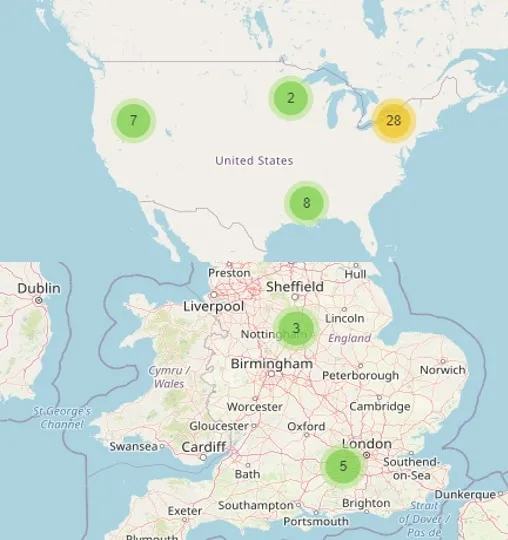

Our network of on-demand manufacturing providers

United States

Canada

United Kingdom

France

Germany

Netherlands

and many more...

FAQ On Demand manufacturing

Discover our other manufacturing services

Get multiple quotes for your parts in seconds