Spark Machining - EDM

Discover what is the manufacturing process CNC Machining Spark Machining EDM and its usage in the industry.

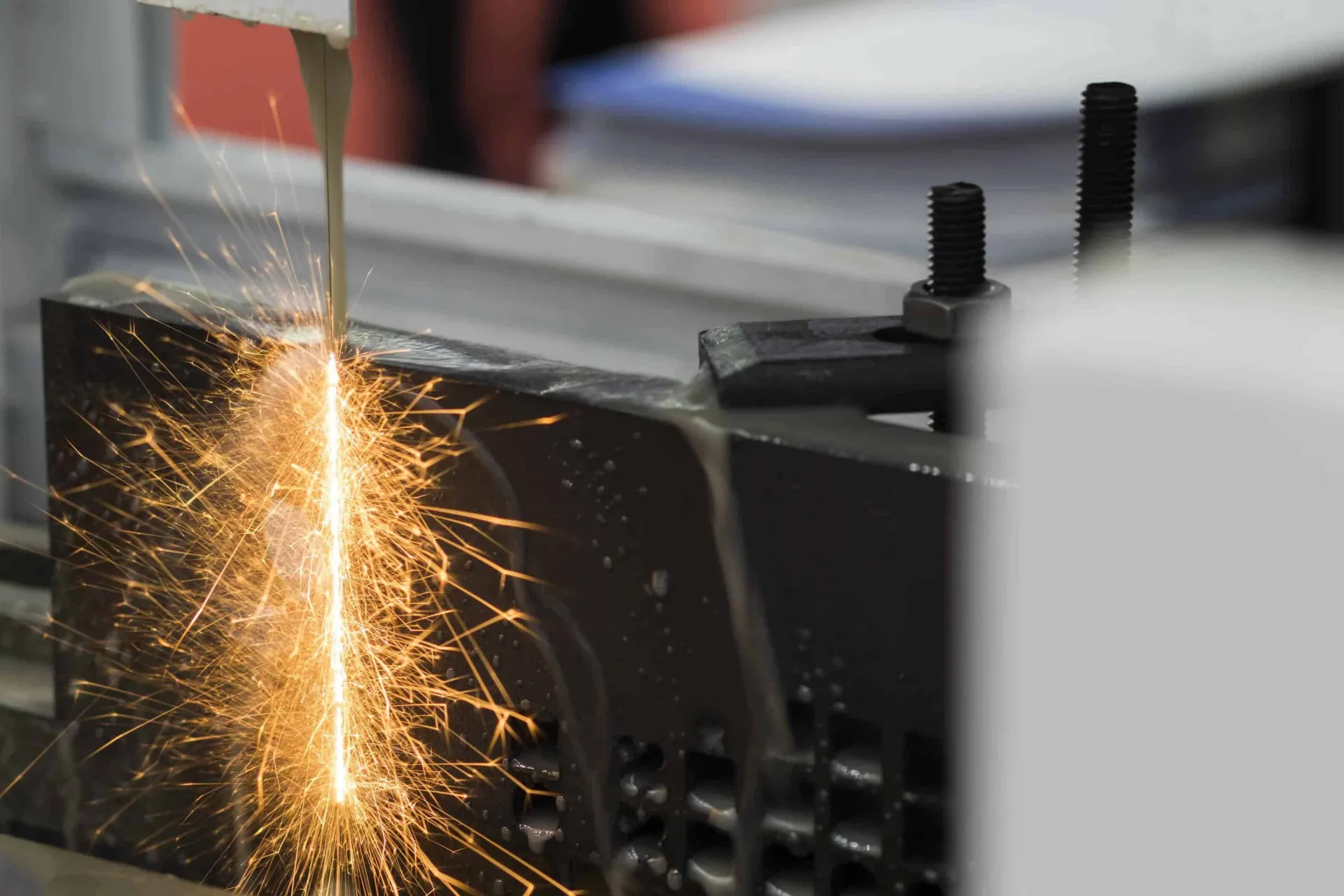

Introduction to Spark Machining

Spark machining is a Substractive machining process that attains the desired shape by producing sparks that melt tiny portions of a metal workpiece. Electrical Discharge Machining (EDM) is another term for that method, spark eroding, burning, die sinking, wire burning, and wire erosion.

Rapid reiterations of electrical current discharges between two electrodes, the tool electrode, and the workpiece electrode, work to remove material from a workpiece without ever making physical contact. This is particularly beneficial for producing fragile parts that cannot absorb the stress of conventional machining.

The English physicist Joseph Priestly first noted the erosive effect of electrical discharges in the second half of the 18th century. Later in the mid-20th century, discoveries in die-sink and wire-cut spark machining happened and launched onto the mass market. Most recently, a portable drill and tap remover have been introduced as an innovative means to remove a broken tap or drill bit from a workpiece.

EDM is primarily a method to manufacture complex shapes with hard metals or those that would be otherwise tough to machine using traditional techniques. Generally, it works with electrically conductive materials, but it is possible to machine insulating ceramics under certain conditions.

Get multiple quotes for your parts in seconds