What is Additive Manufacturing?

Transform your production capabilities with Additive Manufacturing technology, building parts layer by layer to create stronger, lighter components with unprecedented design freedom and efficiency.

What is Additive Manufacturing?

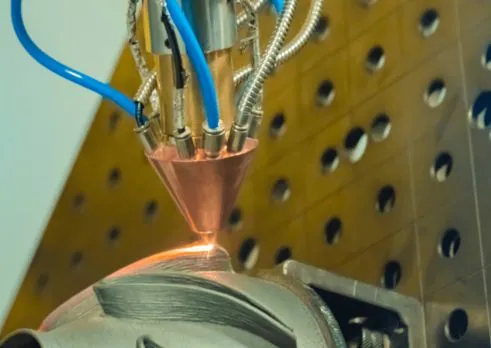

Additive Manufacturing, often referred to as 3D printing, is essentially a synonym for the same technology. Both terms describe the process of building parts layer by layer, using only the material needed for the final component. Unlike traditional subtractive processes, which cut away from bulk material, AM unlocks unprecedented design freedom, supports mass customization and drastically reduces waste.

Rooted in advanced simulation and material science, AM spans prototyping, tooling and end-use production—helping manufacturers design for performance, efficiency and sustainability from the start.

Key Benefits of Additive Manufacturing

Unmatched Design Flexibility

Break free from conventional manufacturing constraints. AM enables intricate geometries, internal lattice structures and consolidated assemblies—empowering engineers to design for optimal function and performance.

Accelerated Product Development

Eliminate tooling bottlenecks and accelerate iteration cycles. AM reduces lead times from weeks to days, enabling faster prototyping and more agile responsiveness to market demands.

Material and Cost Efficiency

By using material only where needed, AM significantly cuts waste and raw material costs. Lightweighting strategies also reduce downstream energy consumption and transportation emissions.

Scalable Mass Customization

Produce personalized or low-volume parts without compromising efficiency. With AM, configuration changes are made digitally—no retooling required—making true customization at scale possible.

Power Sustainable Production with Additive Manufacturing

Sustainable Production

Additive Manufacturing (AM) supports sustainable production by reducing material use, energy consumption and waste.

Design perspective

AM makes it possible to create complex, lightweight geometries through generative design and topology optimization—innovations that traditional manufacturing cannot achieve.

Manufacturing perspective

By building parts layer by layer, AM uses material only where needed, drastically cutting scrap and lowering the environmental footprint. On-demand and local 3D printing further reduce transportation needs and excess inventory.

Real-world example: Ta.Tamu

The Ta.Tamu project, designed with Patrick Jouin, shows how local 3D printing limits cargo shipping and emissions. This foldable chair combines generative design, simulation and life-cycle thinking to demonstrate a regenerative, low-impact approach to design and production.

Additive Manufacturing Across Industries

Discover how advanced AM technologies are transforming production workflows across diverse sectors, delivering competitive advantages through innovation.

Driving Innovation with Dassault Systèmes' Additive Manufacturing Solutions

Explore our comprehensive AM ecosystem designed to optimize every step of your additive workflow—from design and simulation to process planning and production.

Leveraging the power of Virtual Twin technology across our portfolio, Dassault Systèmes connects design, engineering and manufacturing in a unified digital thread. This approach enhances traceability, reduces risks and accelerates innovation, ensuring sustainable and efficient additive manufacturing operations.

Design High-Performance AM Parts

CATIA helps engineers fully exploit Additive Manufacturing with generative design and topology optimization, enabling lightweight, high-performance geometries impossible with traditional methods while fostering seamless design–manufacturing collaboration to speed innovation.

Simulate and Optimize AM Processes

SIMULIA delivers powerful simulation capabilities that enable engineers to predict and optimize AM part performance and build processes. These tools help eliminate costly trial-and-error cycles and ensure first-time-right manufacturing.

Prepare and Control AM Production

DELMIA transforms AM from prototyping to production with integrated build preparation, nesting and process planning tools. This comprehensive approach optimizes machine utilization while ensuring consistent part quality.

Experience the Real-World Value of Additive Manufacturing

Discover how industry leaders are leveraging Dassault Systèmes' Additive Manufacturing solutions to transform their production capabilities and drive innovation.

Use Cases: Key Business Functions of Additive Manufacturing

From design innovation to supply chain transformation, discover how AM is reshaping traditional manufacturing approaches across the product development lifecycle.

Design for Additive Manufacturing

AM-specific design approaches unlock the full potential of additive technologies by incorporating topology optimization, lattice structures and generative design. These methodologies produce components with unprecedented performance-to-weight ratios.

Rapid Prototyping and Iteration

Companies leverage AM to accelerate product development through rapid physical prototyping. This approach enables multiple design iterations in days rather than months, significantly reducing time-to-market while improving final product quality.

Tooling and Fixture Production

Manufacturing operations implement AM to create custom jigs, fixtures and tooling with complex internal features like conformal cooling channels. These applications improve production efficiency while reducing lead times for tooling procurement.

Part Consolidation and Weight Reduction

Engineers redesign multi-component assemblies as single AM parts, eliminating assembly operations while reducing weight and improving performance. These consolidated designs often incorporate internal features impossible with traditional manufacturing.

Regenerative Design: The Ta.Tamu Experience

Ta.Tamu is a collaboration between designer Patrick Jouin and Dassault Systèmes’ Design Studio, illustrating how additive manufacturing can drive sustainable innovation. The lightweight, foldable chair was conceived to be 3D-printed locally, combining generative design, topology optimization, and life-cycle assessment to minimize material usage and environmental impact.

This frugal design demonstrates how art and science, human creativity and digital simulation can merge to support a regenerative economy—promoting local production and empowering self-edition and customization.

Education: Shaping the Future of AM Talent

Universities and industry professionals can access Dassault Systèmes' AM education programs to develop critical skills for the future of manufacturing. These initiatives provide hands-on experience with industry-standard AM tools, preparing students and professionals for careers in advanced manufacturing.

Through specialized curricula and digital learning resources, Dassault Systèmes helps bridge the skills gap in this rapidly evolving field.

Dassault Systèmes' Key Values in Additive Manufacturing

Innovation Acceleration

Our AM platform enables rapid design iteration, virtual testing and process optimization, which significantly reduces development cycles and accelerates time to market.

Sustainable Production

Dassault Systèmes' AM solutions support environmentally responsible manufacturing through material optimization, part consolidation and localized production models.

Future-Ready Technology

Our ongoing investment in advanced AM capabilities ensures our customers stay ahead of manufacturing trends with cutting-edge tools for tomorrow's production challenges.

Scientific Excellence

Dassault Systèmes' AM solutions are built on rigorous scientific principles that ensure accurate simulation, reliable process planning and consistent manufacturing outcomes.

Industry Expertise

With decades of experience across multiple industries, our AM technologies incorporate deep domain knowledge that addresses specific manufacturing challenges in each sector.

Integrated Ecosystem

Our comprehensive approach connects every aspect of the AM workflow from design and materials to production and validation, eliminating data silos and enabling seamless collaboration.

Want to Go Further?

Explore the content below to learn more about Dassault Systèmes and Manufacturing Software.

Additive Manufacturing FAQs

Get in Touch with Our Experts

Fill in the form to have a Dassault Systèmes expert contact you to answer your questions and discuss any of your needs.

Let’s transform your Manufacturing Software journey together—contact us today!