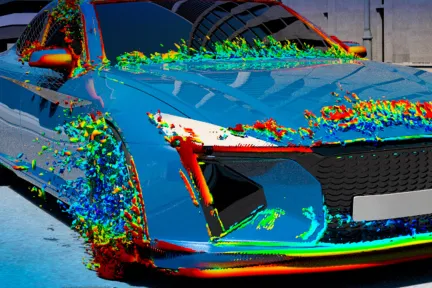

Computational Fluid Dynamics Simulation

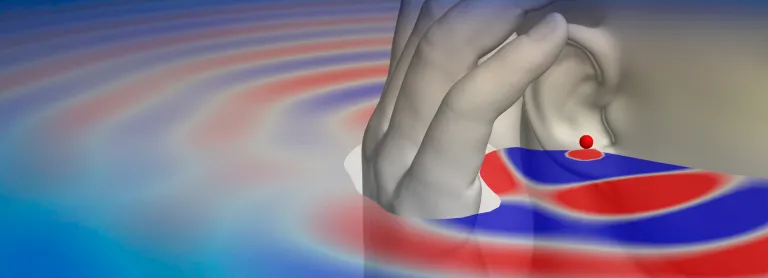

Steady-State and Transient Internal and External Flow Around and Through Solids and Structures

Fast, High-Fidelity CFD Simulation

SIMULIA's Computational Fluid Dynamics (CFD) simulations enable customers to engineer products with precise real-world performance predictions delivered quickly. Our Fluids technologies address diverse challenges across industries and applications, such as eVTOL flight and community noise testing, race-car aerodynamics optimization, and automotive WLTP fuel efficiency certification.

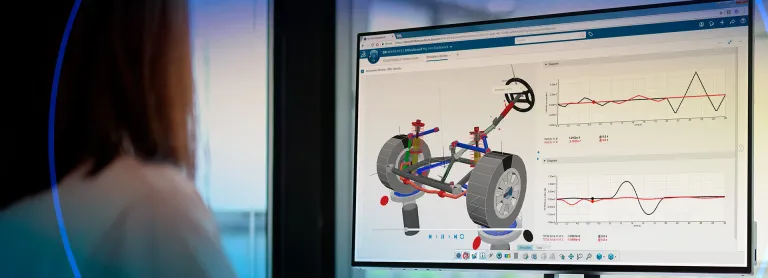

SIMULIA Fluids Simulation is driven by two complementary technologies that provide customers with scalable fluid simulation to address a broad range of real-world applications. PowerFLOW and XFlow offer world-class Lattice Boltzmann method (LBM) technology for high-fidelity simulations that accurately predict real-world performance. Fluid Dynamics Engineer enables multi-scale multi-physical insight by embedding CFD into design, simulation, optimization, data management, and business intelligence applications within the 3DEXPERIENCE platform. In addition, a Plastics Injection Molding application allows validation and optimization of plastic part and mold tooling designs early in the product development process.

SIMULIA Computational Fluid Dynamics Simulation Key Benefits

Faster design turnaround times

Simulation accelerates analysis and optimization, allowing shorter design cycles and providing a competitive advantage

Reduced reliance on testing

Compared to wind tunnel testing, simulation is faster, more cost-effective and can be implemented earlier in the design cycle. It can also reveal behavior not visible in a test

Versatile, high-performance simulation technology

Aerodynamic and aeroacoustic simulation can be performed on large, complex structures and in real-world conditions

Reduced work through automation

Automatic meshing, model-building, visualization and Design of Experiments (DoE) removes tedious set-up work and lets engineers get the results they need faster

Leverage design models

Unified modeling and simulation (MODSIM) means simulation can be performed directly on geometry from CATIA or SOLIDWORKS in a unified design environment, reducing the time needed for model building.

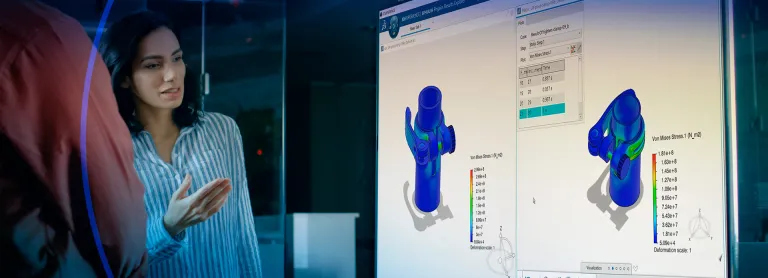

Full analysis with multiphysics simulation

Fluids simulation can be supplemented by other disciplines, such as vibro-acoustic simulation, structures simulation, electromagnetic simulation and multibody system simulation

SIMULIA Fluids Solver Technology

- Navier-Stokes

- Lattice Boltzmann

Navier-Stokes

The physical space to be simulated is divided into many small subdomains called control volumes or cells. The finite volume method is used to discretize the continuum equations that describe fluid motion, known as the Navier-Stokes equations. The resulting set of algebraic equations is solved iteratively to obtain the pressure, velocity, temperature (and other physical quantities) in each cell for steady or unsteady flows. Other discretized transport equations can be solved in the same way to represent other physical phenomena like turbulence and chemical species.

Lattice Boltzmann

Based on a discrete form of the kinetic theory of gases, the Lattice Boltzmann method tracks the microscopic motion of fluid particles through discrete space and time, to simulate the flow of gases and liquids. The fluid space is automatically discretized into cubic voxels, and boundaries into surfels, eliminating the need for conventional surface and volume grid generation. The Very Large Eddy Scale (VLES) turbulence modeling approach ensures that anisotropic fluid structures are captured with high fidelity, which is critical for aerodynamics and aeroacoustics workflows.

Discover the CFD Sub-disciplines

SIMULIA Computational Fluid Dynamics Simulation Software Products

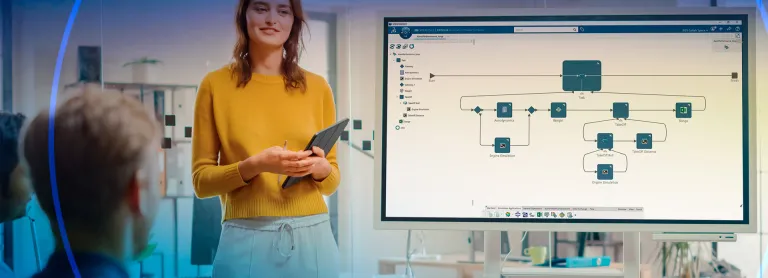

SIMULIA Computational Fluid Dynamics Software on 3DEXPERIENCE Platform

SIMULIA Computational Fluid Dynamics Simulation software products are packaged as Roles on the 3DEXPERIENCE platform to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

Start Your Journey

Explore the technological advancements, innovative methodologies, and evolving industry demands that are reshaping the world of Fluids & Computational Fluid Dynamics. Stay a step ahead with SIMULIA. Discover now.

FAQs About Computational Fluid Dynamics Simulation

CFD simulates the dynamics of fluids such as liquids and gases, as well as suspended particles and mixtures of these. The behavior of fluids is described by models such as the Navier-Stokes equations and Lattice Boltzmann method, with variables such as pressure, density, bulk viscosity, dynamic viscosity, velocity and acceleration. For many scenarios, the equations of fluid dynamics often have no known analytic solution, especially for complex behavior such as turbulence. Therefore, CFD simulation is needed to solve them.

Resolving the fluid flow equations is not trivial - there is no known general analytical solution for the Navier-Stokes equations, meaning that numeric techniques must be used. Boundary Element, Finite Element or Finite Difference methods were among the most common CFD simulation methods initially, but Finite Volume Methods have gained prominence in the past 20 years and are now standard. More recently, increased hardware performance mean that Lattice Boltzmann Methods have also become viable.

As there is no best CFD simulation method for all applications, engineers must choose the right tool for each industrial workflow.

Coupled Eulerian-LagrangianCoupled Eulerian-Lagrangian and smoothed-particle hydrodynamics (SPH) is ideal for highly coupled fluid-structure interaction (FSI) problems such as non-compressible hydraulics. These methods are implemented in SIMULIA Abaqus/Explicit.

The Finite Volume Solver is better suited for steady or moderately transient flows, such as those found in pipe flows, heat exchangers, pumps and HVAC applications. This method is used in SIMULIA Fluid Dynamics Engineer (FMK).

As a transient technique, the Lattice Boltzmann Method (LBM) is more applicable to highly transient flows such as aerodynamics and aeroacoustics. It can handle highly demanding models both in terms of geometric complexity and detail. LBM technology can also be effective for multiphase applications handling complex models that can even include arbitrary moving parts. Dassault Systèmes SIMULIA offers two LBM products. SIMULIA PowerFLOW is ideal for the aerodynamic, acoustic and soiling scenarios common in aerospace and automotive industries. SIMULIA XFlow meanwhile is typically used for complex moving, multiphase problems such as lubrication, sloshing and some Life Science applications.

Both methods are powerful CFD solvers, but they use different approaches and have different benefits. Navier-Stokes methods treat the fluid as a continuum, while Lattice Boltzmann method treats it as discrete particles.

To solve the Navier-Stokes equations computationally, the physical space to be simulated is divided into many small subdomains called control volumes or cells. The equations are discretized across the cells, and the resulting set of algebraic equations is solved iteratively to obtain the pressure, velocity, temperature (and other physical quantities) in each cell for steady or unsteady flows. Additional discretized transport equations can be solved in the same way to represent other physical phenomena like turbulence and chemical species.

The Lattice Boltzmann method of CFD simulation tracks the microscopic motion of fluid particles through discrete space and time, to simulate the flow of gases and liquids. The fluid space is automatically discretized into cubic voxels, and boundaries into surfels, eliminating the need for conventional surface and volume grid generation. The Very Large Eddy Scale (VLES) turbulence modeling approach ensures that anisotropic fluid structures are captured with high fidelity, which is critical for aerodynamics and aeroacoustics workflows.

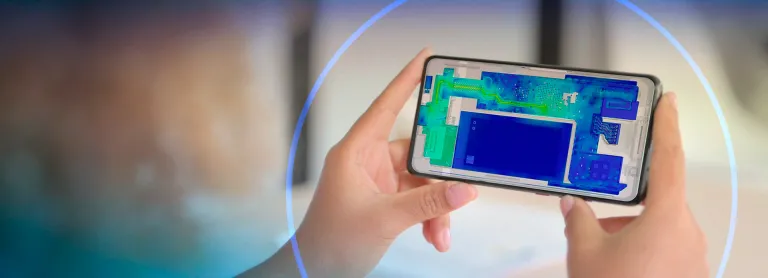

Yes, several high-performance computing (HPC) techniques can accelerate CFD simulation. GPU acceleration speeds up the simulation process and allows larger and more complex models to be simulated on a single workstation. One GPU can have the power of over 1000 CPU cores - GPUs reduce hardware cost and enable desktop supercomputing. Multi-GPU acceleration provides even more speed-up, solving extremely large or complex scenarios that cannot be simulated otherwise. GPU benefits all CFD codes, but is especially effective for Lattice Boltzmann Method (LBM) simulation.

Cluster computing can simulate even larger scenarios. Cloud offers greater control of batch simulation processes. Both on-premises and online cloud are available. On-premises cloud uses hardware operated by the user’s company, while online cloud sends the data to secure servers for processing. Online cloud is a good option for users with irregular or periodic simulation needs, avoiding the need to invest in hardware that would only be used occasionally.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering