SIMULIA

Reveal the World We Live In

SIMULIA simulation software accelerates the process of evaluating the performance, reliability and safety of materials and products before committing to physical prototypes. Explore the engineering disciplines that we support.

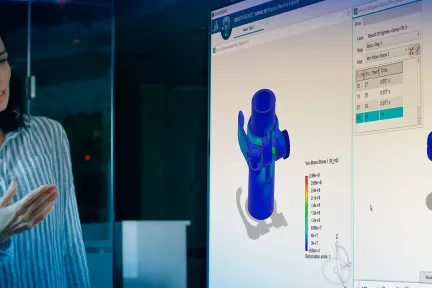

Finite Element Analysis for Mechanical and Civil Engineering

Simulation and Analysis of Electromagnetic Fields

Steady-State and Transient Internal and External Flow Around and Through Solids and Structures

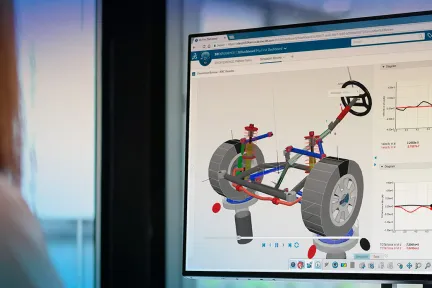

Analyse the Motion of Complex Mechanical Systems Under the Application of Mechanical Forces

Simulation and analysis of noise and vibration across the entire audible frequency range

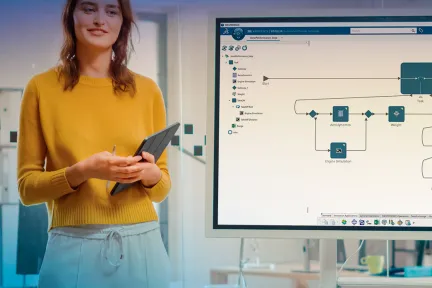

Democratize Simulation, Accelerate Innovation, and Take Advantage of the Power of Artificial Intelligence.

SIMULIA Portfolio

Explore our Software and Solutions

Featured Topics

Discover the world of SIMULIA

MODeling & SIMulation on the 3DEXPERIENCE platform

Get more from your simulations and work more efficiently with AI-assisted performance-driven design with machine learning.

Reveal the Future With Simulation in the Cloud

Simulation of Connected Systems and Devices Enables Efficient Product Design and Certification

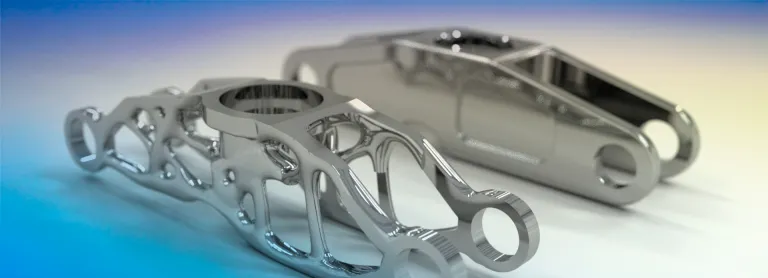

Explore the Future of Fabrication with SIMULIA's Advanced Digital Additive Manufacturing Solutions

Simulations optimize EV design, enhance performance, and shape the future of sustainable transportation

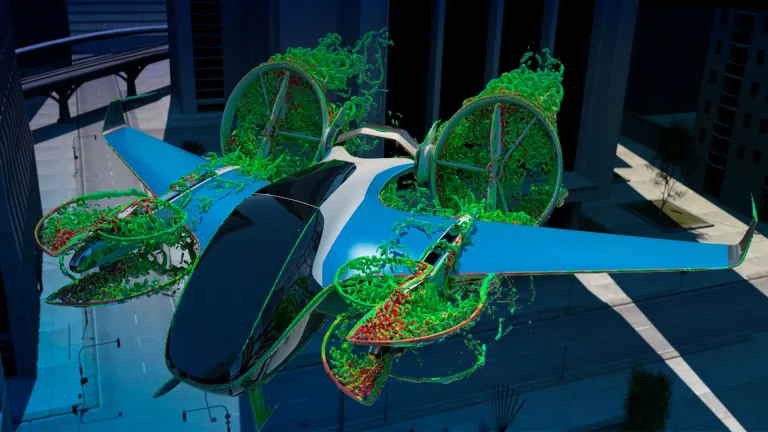

Simulation for Urban Air Mobility (UAM)

News & Offers

Customer Stories

How Companies are Using our Design & Engineering Simulation Solutions

Helix

The Next-Generation Electric Powertrains

Electric powertrain developer Helix has broken records and won awards for its high-performance electric motors and inverters. It is driving continuous improvements with 3DEXPERIENCE to achieve a finely tuned design and streamline engineering process from concept to manufacturing.

The 3DEXPERIENCE is at the center of everything we do in terms of design and then following through to production.

Blogs

Read the SIMULIA blog on the latest news and innovations from our experts.

User Communities

Providing essential SIMULIA resources and active engagement with fellow users

SIMULIA Champions Program

The SIMULIA Champions Program pays tribute to our most active and influential simulation experts and brings them together to advance the future of simulation.

Our Champions are brand ambassadors who share their extraordinary expertise with other users, inspire peers, provide important feedback and enrich our SIMULIA community.

E-Seminars

E-books, Whitepapers & other Resources

Connect with SIMULIA

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering