Kobelco Construction Machinery

Kobelco Construction Machinery leverages the Single Source for Speed and Integrated Heavy Machinery solutions to optimize design processes and improve access to information across its organization.

Our market is evolving rapidly. We must differentiate ourselves by providing high quality, high performing and compliant solutions as well as maintenance and service capabilities… We believe we can do this with the Dassault Systèmes technology.

Building on Decades of Heavy Machinery Innovation

About ninety years ago, Kobelco Construction Machinery, a subsidiary of major Japanese steel manufacturer Kobe Steel, created Japan’s first electric mining shovel – a feat of engineering innovation that set the tone for decades of pioneering technological developments. The KOBELCO SK3500D, for example, was listed by Guinness World Records for operating at the world’s highest work height of over 65 meters and is currently the world’s largest building demolition machine.

To build on its strong foundation of heavy machinery innovation and continue to transform, Kobelco Construction Machinery is strengthening its partnership with Dassault Systèmes, a collaboration which began back in 2000 when it implemented CATIA V5 for design and ENOVIA SmarTeam for product data management.

“Our market is evolving rapidly,” said Yoshiaki Shishido, Kobelco Construction Machinery’s group manager of total support group and general manager of global IT system department. “We must differentiate ourselves by providing high quality, high performing and compliant solutions as well as maintenance service capabilities. To succeed, we need to advance our digital transformation and be better equipped to utilize vast amounts of data. We believe that we can do this with Dassault Systèmes technology.”

New Opportunities for Growth

While Kobelco Construction Machinery has made great strides in leveraging CATIA V5 for 3D modeling in new product development – resulting in shortened product design and improved design cycle times – it was doing so using various highly customized legacy solutions which posed a challenge by restricting information utilization to only a limited part of the organization.

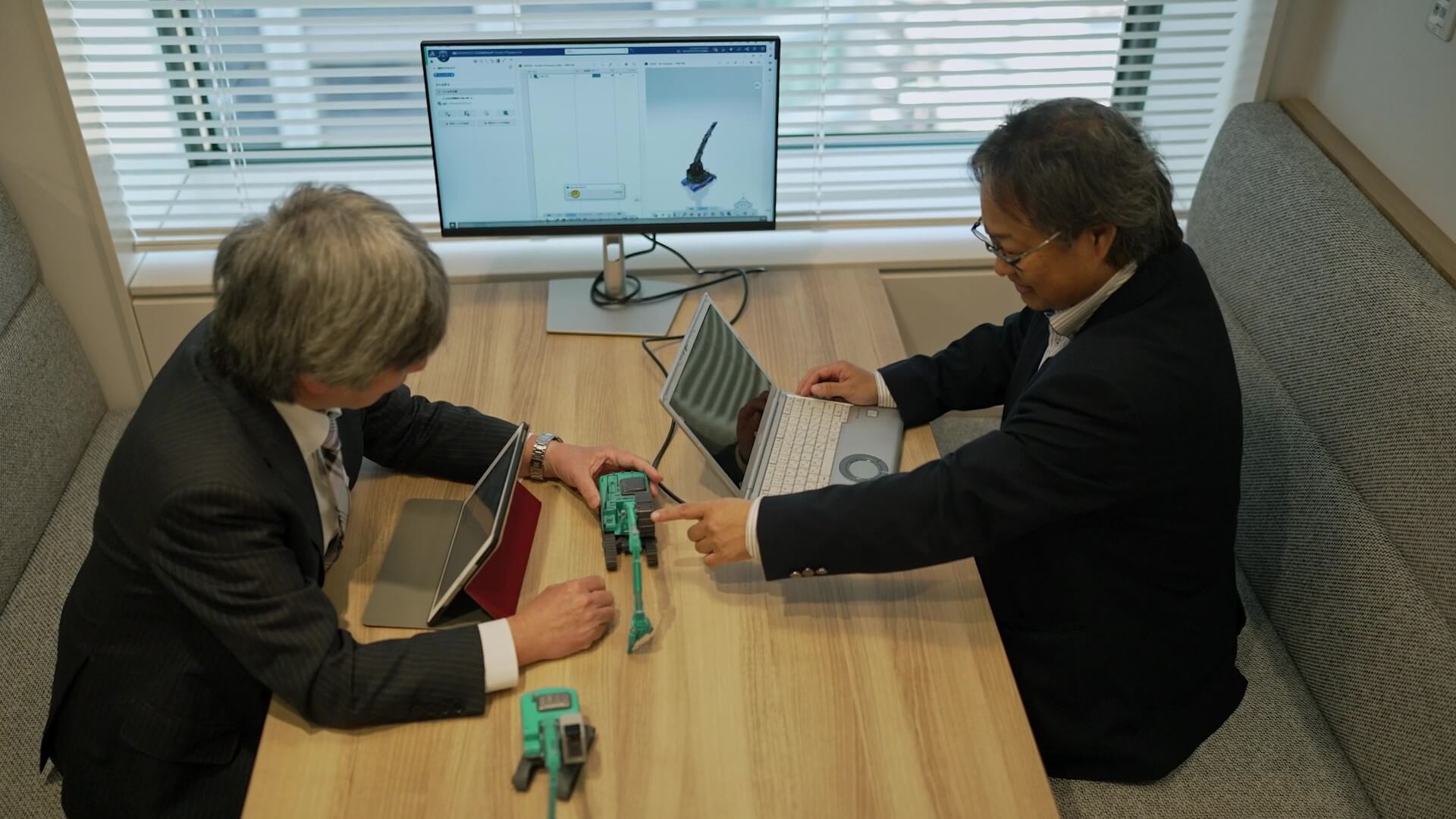

“Over the years, we have adopted several separate, individually optimized applications,” said Kentaro Harada, group manager of the engineering chain management system group in Kobelco Construction Machinery’s global IT system department. “Our design teams are dispersed across our factories in Japan, China and India. They all need to work on the same product designs. But, without access to a centralized system, they must manage their data independently. This data is currently shared overnight via an in-house system – a cumbersome process that has led to duplicated data and long wait times for everything to synchronize.”

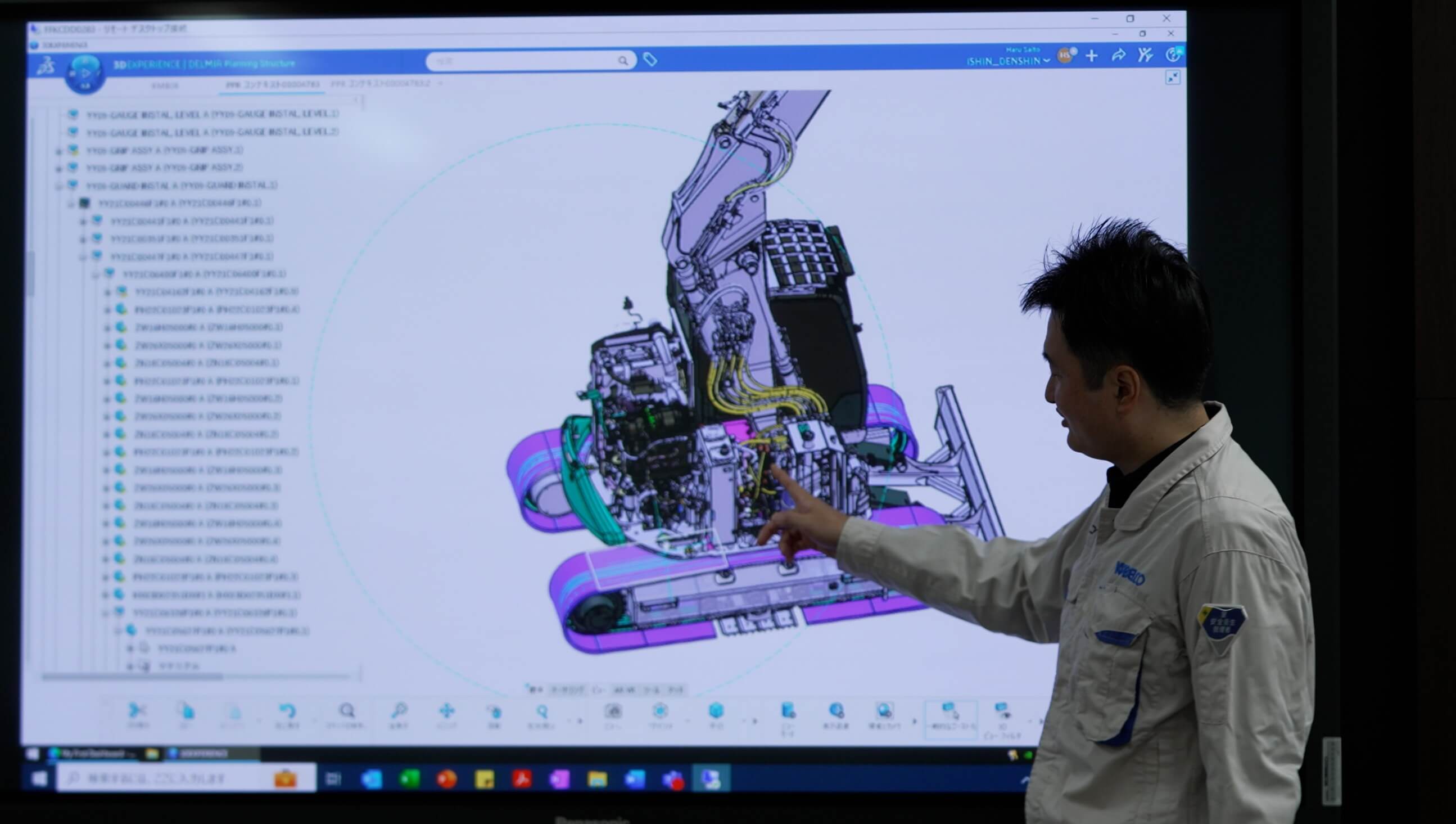

At the same time, Kobelco Construction Machinery’s system was unable to manage large assemblies – a key challenge given the size and complexity of its products. “We were unable to open a 3D model of a single construction machine, so design work had to be done in phases,” Shishido said.

In addition, without the ability to share 3D design data with other non-engineering departments, the company’s product sales and after-sales service teams have limited access to data. “In our make-to-order business, without access to 3D models, it is very difficult for our sales team to show the customer what their product will look like in advance,” Shishido said. “This makes it hard to accurately communicate product specifications.”

Embarking on a Proven Business Transformation Process

Executives at Kobelco Construction Machinery realized that, by embracing Dassault Systèmes’ cutting-edge digital technologies out-of-the-box, they could not only address their existing challenges, but also drive innovation.

To ensure it gets the most out of its adoption of new technology, Kobelco Construction Machinery has embarked on the Dassault Systèmes Value Engagement process, an approach that sees it journey through four distinct stages: Value Assessment; Value Definition; Value Commitment; and Value Delivery.

In the Value Assessment stage, Dassault Systèmes worked closely with Kobelco Construction Machinery to analyze its current business and determine key requirements. During the Value Definition stage, Dassault Systèmes helped the company to define its roadmap for implementing its new solutions and identify the value it will get from the rollout. The third stage, Value Commitment, helped the company’s various teams prepare for implementation and, following the final Value Delivery stage, the company successfully went live in May 2025. The company is now considering a second Value Engagement process to further expand the adoption of solutions.

Expediting the Heavy Machinery Design Process

Since all design data will be accessed from a single unified environment, Kobelco Construction Machinery’s various teams will no longer have to wait for data to be shared overnight between locations. “We expect to speed up the design speed significantly by strengthening collaboration between domestic and overseas design departments,” Shishido said.

CATIA’s ability to handle large assemblies will also enable transformation of the design process. “By using the 150% BOM function, engineers can design about 300 variations of product specifications effectively,” Harada said. “This means it becomes possible to visualize the product as a whole, including option specifications, while improving the standardization ratio and promoting modular design based on comprehensive spatial planning.”

CATIA will also make it much easier for Kobelco Construction Machinery’s designers to consider the commonality and modularization of structures and parts. “We will be able to apply changes to a common part at the touch of a button, instead of having to open and change each 3D model,” Shishido said.

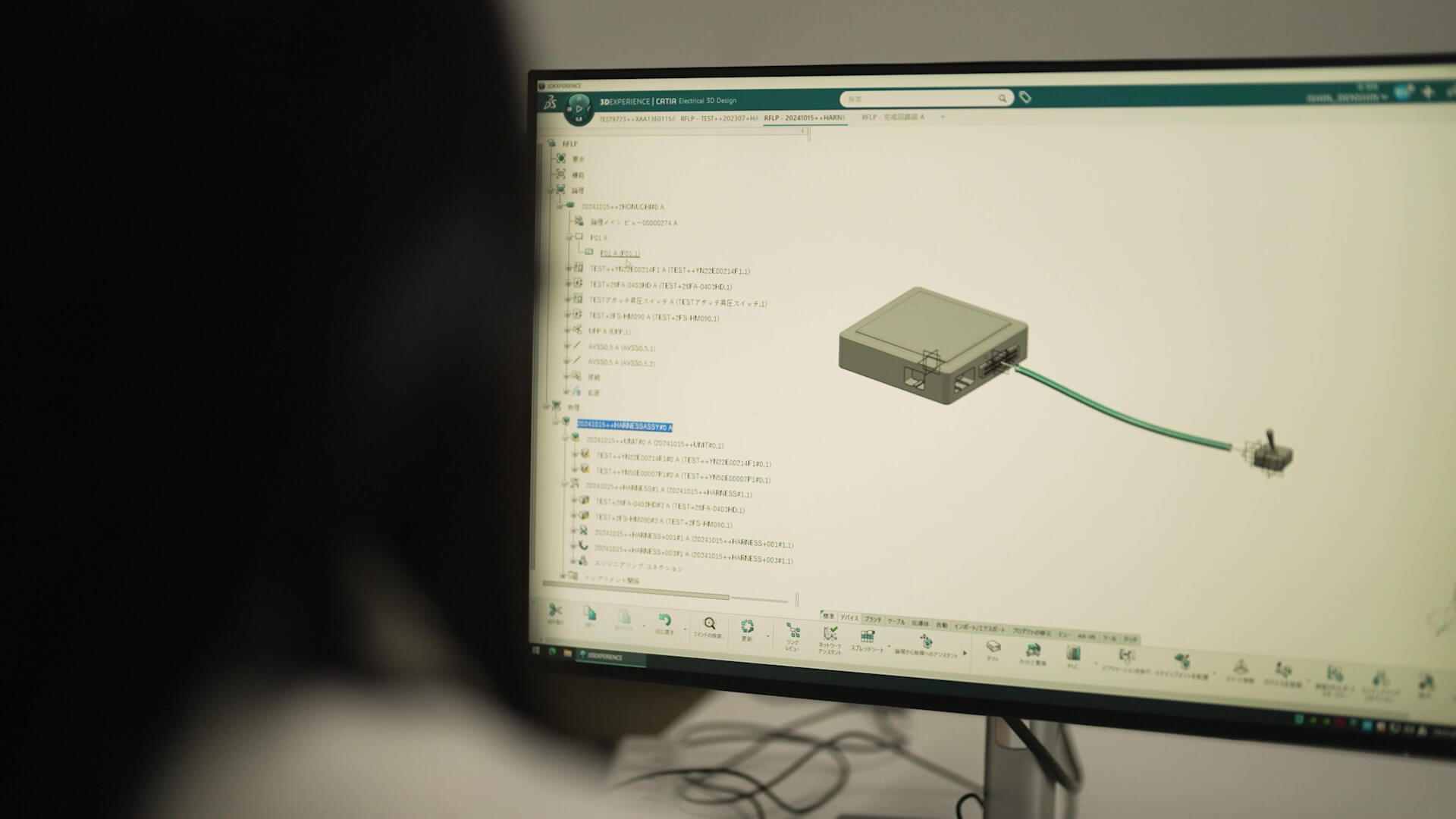

“I’m using 3DEXPERIENCE CATIA for electrical control design, and the ability to link the circuit design with the harness design is the best feature,” said Tomomi Kan, a designer in Kobelco Construction Machinery’s planning group in the development operation management department of the product development engineering division. “For example, when there’s a design change in the circuit, it’s immediately reflected in the harness design as well.”

Meanwhile, SIMULIA will be used to help Kobelco Construction Machinery’s engineers perform structural analysis. “We believe SIMULIA will help improve the accuracy of physical prototyping so that we can begin mass production in about half the time we usually take,” Shishido said.

By accelerating the engineering process and overall organizational efficiency, Kobelco Construction Machinery expects to provide products and services that enhance corporate value, and further advance its sustainability as a company.

Democratizing Data

ENOVIA’s product data management capabilities will allow 3D models to be used throughout the entire global company – and everyone will have access to a single unified BOM. This is expected to be transformational for all departments within Kobelco Construction Machinery.

“We plan to use 3D models as the basis of both a quotation system and a product parts catalog system for product sales,” Harada said. “This means we can increase the certainty of orders for our construction equipment and the accuracy of confirming customer requirements and product specifications, thereby reducing rework.”

By creating a more structured and formalized procurement process based on historical purchasing data using NETVIBES, Kobelco Construction Machinery expects to be able to make smarter purchasing decisions. Currently, Kobelco spends €400 million (56 billion yen) annually on purchased parts. By gaining more accurate data about these parts, the company will be able to procure them from the optimal supplier, at the right price and at the right time. In addition, it will be possible to strengthen price negotiations, consolidate suppliers and minimize excess inventory. If procurement costs are reduced by just 2%, this could result in annual savings of €8 million (1.1 billion yen).

Improving Production Processes

The smart factory capabilities of DELMIA offer further value. “With DELMIA, we analyze the variation between the simulated workload and actual work time at each workstation, improving accuracy,” Shishido said. “If each plant will be able to reduce cycle time from 15 minutes to 12 minutes, it will increase production from 10,000 units per plant per year to 12,000 units per plant per year.”

Once the current implementation is complete, Kobelco Construction Machinery will leverage additional platform capabilities. “We plan to use DELMIA Apriso’s manufacturing execution system to manage the quality inspection process more appropriately in our overseas plants and to estimate shipping weights,” Shishido said.

We believe that showing customers our products in action helps them better understand our products and allows us to have more meaningful conversations with them.

A Customer-Oriented Future

Kobelco Construction Machinery also plans to use NETVIBES to capture customer feedback and requirements to leverage for product and market marketing. “Our service staff and salespeople engage directly with customers and value the feedback they receive,” Shishido said. “By capturing this information and leveraging insights from it, we will ensure our products meet customer needs. We will also be able to develop more targeted marketing campaigns.”

This isn’t the only way Kobelco Construction Machinery will make better use of its data to improve the customer experience. By using 3DEXCITE, it will be able to create compelling marketing collateral that brings its products to life. “We believe that showing customers our products in action helps them better understand our products and allows us to have more meaningful conversations with them,” Shishido said.

To help it advance its ability to embrace new features and functionality offered by Dassault Systèmes technology, Kobelco Construction Machinery’s immediate priority is to transition to the cloud. To this end, Dassault Systèmes is working with the company to expand its cloud strategy. As part of the project, the cloud has been leveraged as an environment for evaluating new capabilities, yielding significant results. Looking ahead, the company is also considering migrating its production environment to the cloud.

Kobelco Construction Machinery is also expanding its use of virtual twins. “It’s one of our goals to be able to leverage virtual twins to predict what will happen in the real world,” Shishido said. “By identifying and resolving issues before production, we can achieve more precise manufacturing. Accurate maintenance work instructions will also lead to quicker product restoration and minimize downtime. Ultimately with these capabilities, we strive to maximize customer value and satisfaction, achieve lasting growth and become a leading global brand known for innovation.”

Focus on Kobelco Construction Machinery

Kobelco Construction Machinery is a provider of hydraulic excavators and crawler cranes, having continuously supplied products, services and information to their customers since their first construction machinery release in Japan, in 1930. Its sales and distribution network covers almost the entire world, including production bases with four factories in Japan, and one each in China, Thailand and India.

For more information: https://www.kobelcocm-global.com/

Focus on Kobelco Systems

Kobelco Systems’ mission is to respond to its customers’ diverse needs. The company has a wealth of business expertise, built up through first-hand experience in its customers' industries. Kobelco Systems combines this expertise with its know-how concerning the conception, design, development, maintenance and operation of advanced systems, drawing on its group companies' extensive experience in constructing IT systems worldwide.

For more information: https://www.kobelcosys.co.jp