Additive Manufacturing Simulation

Explore the Future of Fabrication with SIMULIA's Advanced Digital Additive Manufacturing Solutions

What is Digital Additive Manufacturing Simulation?

Digital Additive Manufacturing (DAM) is an advanced fabrication process in which parts or objects are built layer by layer through material addition. Traditional subtractive manufacturing methods, such as turning, drilling, and milling, remove material to achieve a desired shape. In contrast, additive techniques utilize 3D printing technology to develop components directly from digital models.

How does Digital Additive Manufacturing work?

In Digital Additive Manufacturing, a Digital Mock-Up (DMU) of the part or fabrication bed is created. This involves:

- Three-dimensional CAD representations: Geometric designs that depict the intended final product.

- Fabrication process representations: Detailed descriptions of methodologies, including material extrusion, recoating, scan paths, and energy deposition.

The entire process is managed digitally, and the resulting digital thread is converted into machine code, which gives specific commands for machines to follow during fabrication.

How does Simulation help in Digital Additive Manufacturing?

Additive Manufacturing (AM) presents unique challenges, but simulation transforms these obstacles into opportunities for innovation.

- Optimizing Design: AM's design freedom requires new paradigms. Simulation helps explore optimal forms while ensuring support structures are effectively integrated to prevent fabrication failures.

- Understanding Performance: Phase changes, driven by chemical reactions and thermal processes, significantly influence product performance. Simulation allows for predicting residual stresses and distortions that can arise during fabrication, enhancing overall reliability.

- Advanced Tools for Success: Simulation technologies, such as finite element analysis and computational fluid dynamics, enable virtual process testing and reverse product engineering. These tools provide valuable insights that refine design and production.

- Driving Efficiency: Using simulation capabilities, manufacturers can reduce development cycles, cut costs, and improve decision-making. The ability to anticipate and address potential issues before they arise mitigates program risks and ensures high-quality outcomes.

Key Benefits of Additive Manufacturing Simulation

Material Savings

Minimize waste and utilize advanced materials (e.g., TPU filaments, metal superalloys).

Design Flexibility

Use generative design techniques to create intricate geometries and lightweight structures.

Streamlined Processes

Consolidate multiple components into one part, cutting assembly time and costs.

Enhanced Sustainability

Promotes environmentally friendly manufacturing practices.

Elevate Collaboration with the 3DEXPERIENCE Platform

Digitalization minimizes time-to-market and costs by shifting design from linear to collaborative processes. Collaborative Engineering emphasizes efficient content sharing across the product lifecycle.

Design for Additive Manufacturing (DfAM) involves a multidisciplinary approach, utilizing generative design and topology optimization to reveal new opportunities. Virtual testing through simulations provides critical insights into build failure predictability and post-build product performance, which are closely tied to manufacturing processes and design specifications.

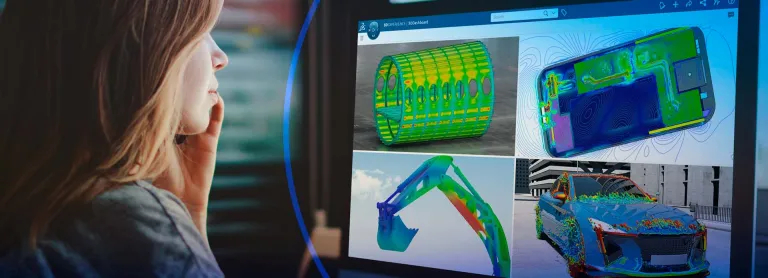

The 3DEXPERIENCE platform enables seamless data integration across disciplines, supports content lifecycle management, and cultivates a collaborative engineering environment. Effective content lifecycle management, maturity, and robust data organization enhance issue resolution, change management, routing, and testing, fostering a productive collaborative atmosphere.

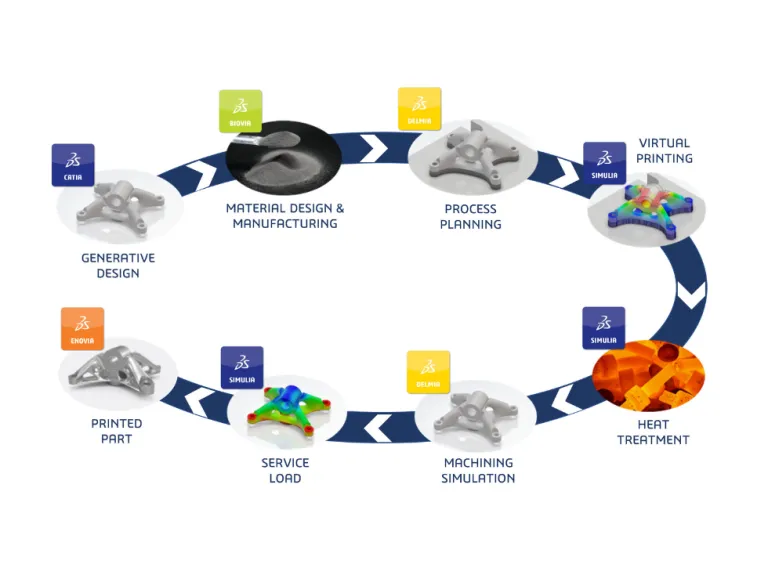

Additive Manufacturing Digital Thread

Dassault Systèmes offers a portfolio of integrated applications to maximize the capabilities of additive manufacturing techniques by connecting all disciplines for an authentic end-to-end development chain from product design to manufacturing and simulation. The 3DEXPERIENCE platform provides numerous advanced roles and a rich set of powerful applications to cover all aspects of digital product development. The digital thread provided by the 3DEXPERIENCE platform ensures a tight connection between these powerful and intuitive applications, as highlighted in the tabs below.

- 3DEXPERIENCE Marketplace

- Function-Driven Generative Design

- Part Selection

3DEXPERIENCE Marketplace

3DEXPERIENCE Make is an on-demand manufacturing platform that connects designers and engineers with industrial manufacturing service providers. It connects the industrial ecosystem of Designers, Engineers, Buyers, and Production planners with industrial manufacturing service providers such as Xometry, Sculpteo, American Additive, Get It Made, Any-Shape, and more.

With our robust algorithm, you can get quotes in seconds from our network of service providers for your 3D printing and CNC machining project.

Function-Driven Generative Design

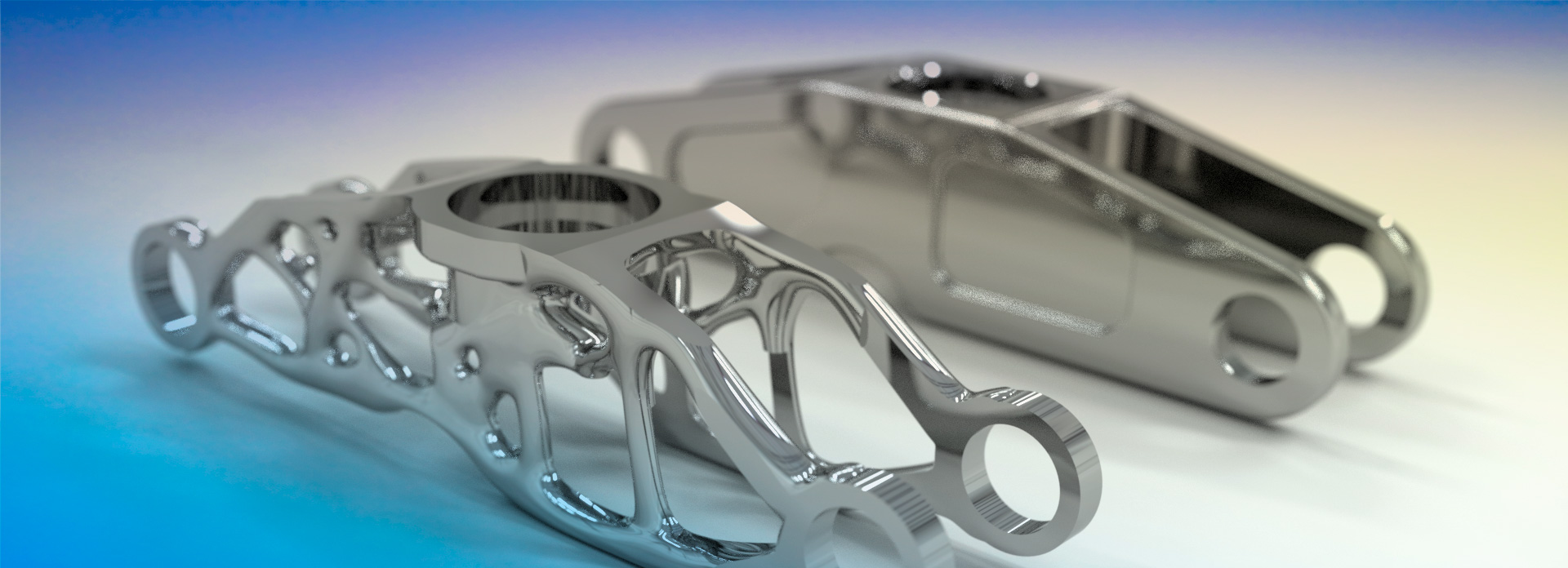

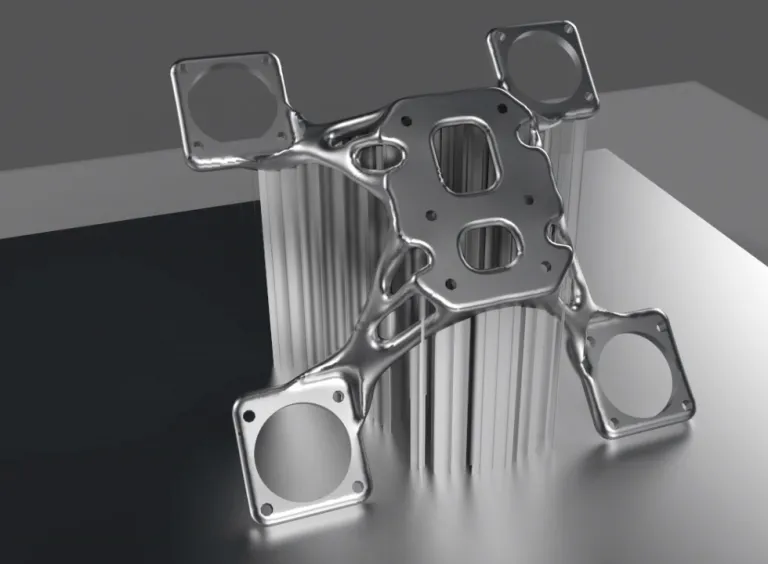

The emergence of additive manufacturing techniques enables the creation of efficient organic shapes and complex lattice structures that go beyond traditional engineering design. Unlike conventional methods that rely on best practices and an engineer's experience, Generative Design focuses on achieving optimal designs for specific functions based on defined constraints.

Additive manufacturing provides the flexibility to establish functional constraints that define design volumes, control mechanical interfaces, and target metrics like mass, stiffness, strength, and durability—all without restricting form. The Generative Approach within 3DEXPERIENCE integrates design, simulation, and optimization through guided workflows, delivering a streamlined solution for users within a single interface.

Part Selection

Powerful search tools in 3DEXPERIENCE can evaluate your part library and digital bill of materials to identify potential candidates for additive manufacturing.

Digital collaboration and intelligence on our platform ensure seamless real-time information sharing between all stakeholders so that product designers, engineers, and managers have a full view of the project at all times.

- Process Design & Production Planning

- Virtual Printing

- Materials Engineering and Development

Process Design & Production Planning

Fabrication applications on the 3DEXPERIENCE platform provide guided workflows to design and plan production and production processes associated with Additive solutions and machines. Commencing with creating or reusing build volumes and plates, automatically nest parts to maximize build volume usage, capture and reuse rules to assess optimal part orientation and compute minimal support structures. Specify custom rules for slicing, scan patterns and process parameters for the entire build or individual parts. Visualize the scan path for diagnostic checks and reuse process data in downstream Virtual Printing simulations and studies.

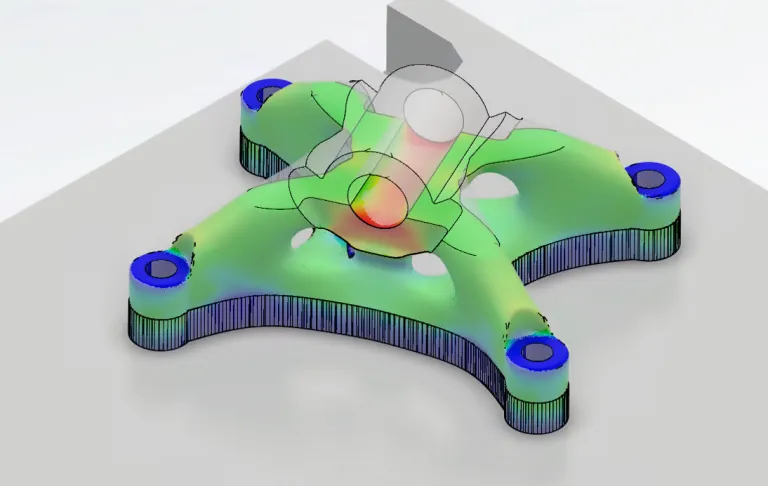

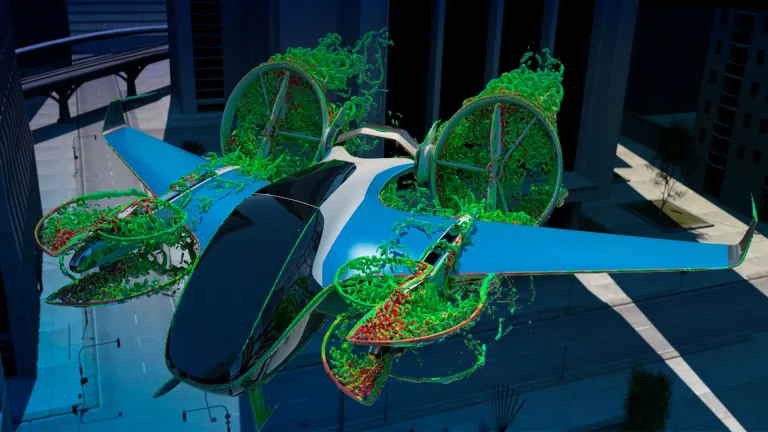

Virtual Printing

Use the 3DEXPERIENCE platform to lower time and material costs. Simulate part-build behavior and process sensitivities, including scan path and support structure performance. Accelerate simulations by integrating and reusing design data. Create user interfaces and workflows for manufacturing methods like Direct Energy Deposition, Select Laser Sintering, or Polymer Extrusion. Apply validated thermal-mechanical solutions to predict distortion and residual stress while identifying risks such as crack initiation and machine interference. Include assessments of fatigue life, account for post-build heat treatment, and ensure as-manufactured geometry matches as-designed geometry through digital compensation.

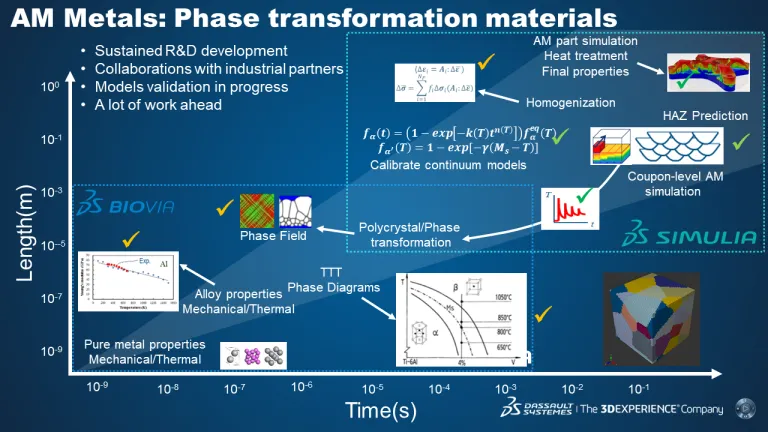

Materials Engineering and Development

Create virtual printers with multiple lasers or heat sources to control material deposition and removal while optimizing cooling methods for advanced manufacturing. Design metal alloys for additive manufacturing by analyzing micro-mechanics simulations to understand grain orientation and phase properties. With user-defined material models and comprehensive process parameters in our thermal-mechanical simulations, you can precisely engineer manufacturing processes and material properties for demanding AM applications. Coupled with powerful optimization tools in 3DEXPERIENCE, you have complete control over advanced AM process workflows.

Customer Testimonials

Listen to our customers in their own words. Check out these videos.

Start Your Journey

The world of Digital Additive Manufacturing is changing. Discover how to stay a step ahead with SIMULIA

Additive Manufacturing Resources

External Resources for Additive Manufacturing Simulation

America Makes and Air Force Research Laboratory Challenge Series: Winner Macro-scale Process-to-Structure Predictions

- AFRL AM Challenge Series Improved Understanding of the Internal Structure and Resultant Performance of Metallic Components Produced by AM | America Makes (July 20,2020)

NIST AM-BENCH Test Series: Best Results Predicting Residual Stresses

- AM-Bench 2018 Benchmark Challenge Submissions and Awards | NIST (June 20,2018)

Full thermal-mechanical simulation methods for accurate distortion and stress prediction, including buckling

- Effective residual stress prediction validated with neutron diffraction method for metal large-scale additive manufacturing | Materials and Design -Journal- Elsevier (July 2021)

The full thermal-mechanical solution provides a detailed thermal response that can be used to predict microstructure properties including melt pool, unfused powder, phase transformation, grain morphology, and mechanical properties

- Estimates of the mechanical properties of laser powder bed fusion Ti-6Al-4V parts using finite element models | Materials and Design -Journal- Elsevier

- A metallurgical phase transformation framework applied to SLM additive manufacturing process | Materials and Design -Journal- Elsevier

Advanced solver capabilities

- Reduced order modeling via PGD for highly transient thermal evolutions in additive manufacturing | Computational Methods in Applied Mechanics and Engineering

PARTNERSHIPS

- Join the DELMIA Fabrication Community to learn how to connect additive manufacturing printers to the 3DEXPERIENCE platform

- Learn how Renishaw and Dassault Systemes work together to deliver a no-compromise end-to-end AM design experience

NEWS

- Dassault Systèmes in Additive Manufacturing | additivemanufacturing.com

- RIZE and Dassault Systèmes partner to enhance additive manufacturing user experience | tctmagazine.com (December 10, 2019)

- Science in the Age of Experience: Additive Manufacturing Symposium Draws Expert Discussion on Progress, Challenges | 3DPrint.com (Jun. 20, 2018)

- Aerospace, Architecture, Consumer Applications Highlight 3D Printing Usage in Additive Manufacturing Symposium | 3DPrint.com (Jun. 21, 2018)

- Expert Discussion Looks to the Future of 3D Printing, Supply Chain, Democratization | 3DPrint.com (Jun. 21, 2018)

- Workforce is Key to the Development of Additive Manufacturing: Interview with Women in Manufacturing | 3DPrint.com (Jun. 20, 2018)

- Bursting Additive Manufacturing’s Last Bubbles | Rapid Ready Tech (Jun. 20, 2018)

- Mainstreaming of Additive Manufacturing: An Ecosystem Perspective | 3DPrint.com (Jun. 22, 2018)

FAQs about Additive Manufacturing Simulation

The 3DEXPERIENCE platform integrates design, simulation, and production workflows, enabling seamless collaboration and data management. It helps optimize processes, improve accuracy, and accelerate product development cycles.

Many industries benefit from SIMULIA's additive manufacturing capabilities, including aerospace, automotive, and medical sectors. These industries require high-performance components with intricate designs that traditional manufacturing methods cannot achieve. By utilizing SIMULIA's tools, companies can innovate faster and significantly improve their product offerings.

Yes, SIMULIA supports multi-material additive manufacturing by allowing simulations that account for different material properties and interactions. This capability enables designers to create more sophisticated parts that harness the strengths of various materials, optimizing performance and functionality.

SIMULIA is a useful tool for additive manufacturing. It offers simulations that optimize designs by analyzing material behavior and thermal effects. This can enhance part quality and streamline workflows with other Dassault Systèmes tools.

Through advanced simulations, SIMULIA tackles common challenges in additive manufacturing, such as thermal distortion and material weaknesses. By modeling the additive process, users can gain insights into potential defects and make necessary adjustments during the design phase. This proactive approach minimizes errors and wasted materials, ultimately leading to cost savings and improved product quality.

- Vat Photopolymerization – Uses liquid resin cured by light (e.g., SLA - Stereolithography, DLP - Digital Light Processing)—example: High-detail prototypes in automotive and medical industries.

- Material Jetting Deposits droplets of material layer by layer (e.g., PolyJet, NanoParticle Jetting). An example is full-color, multi-material prototypes for product design.

- Binder Jetting – Binds powder materials using a liquid agent (e.g., sand, metal, or ceramic printing)—examples: Metal casting molds, sand cores, and architectural models.

- Powder Bed Fusion (PBF) – Uses a laser or electron beam to fuse powder particles (e.g., SLS - Selective Laser Sintering, DMLS - Direct Metal Laser Sintering, EBM - Electron Beam Melting). Example: Aerospace and medical implants due to high strength and precision.

- Directed Energy Deposition (DED) uses a focused energy source (laser, electron beam, or plasma) to melt material as it is deposited. Examples include repairing and building large metal parts in aerospace and defense.

- Material Extrusion Deposits material through a nozzle (e.g., FDM—Fused Deposition Modeling). Examples include consumer 3D printing, jigs, and fixtures in manufacturing.

- Sheet Lamination Bonds thin sheets of material layer by layer (e.g., UAM—Ultrasonic Additive Manufacturing, LOM—Laminated Object Manufacturing). Examples include low-cost prototyping and hybrid manufacturing for metal components.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering