Course Descriptions

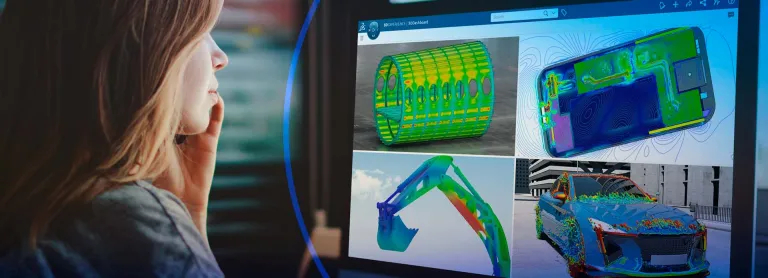

Explore the Possibilities of Deepening your Simulation Knowledge

Training Course Descriptions

Most SIMULIA training courses are available as instructor-led or on-demand training. Expand a topic below to find the available training courses. Click the link in the section heading to download a catalog with descriptions of the courses in that library. To find the schedule of public training for a course, click the course title.

To find out more about subscriptions to our on-demand libraries, visit Learning Experiences for SIMULATION. To request a DS instructor-led training, find a partner to deliver training and more click here.

To find a description of the courses in this section, download the SIMULIA 3DEXPERIENCE Courses catalog.

The following courses are available on-demand. Click below to see the table of contents for each course. To find out more about accessing these on-demand courses, visit Learning Experiences for SIMULATION.

- 3DEXPERIENCE Simulation Primer for Abaqus/CAE Users

- Abaqus Study Essentials

- Connector for Abaqus/CAE Essentials

- Connector for CST Essentials

- Connector for PowerFLOW: Connecting PowerDELTA and 3DEXPERIENCE

- Connector for Simpack Essentials

- Explore the Structural Performance Engineer Role

- Getting Started with Automation and Optimization

- Getting Started with Physics Simulation

- Physics Simulation Review Essentials

- Process Experience Studio Essentials

The following courses are available as both instructor-led and on-demand. Click below to see the global public training schedule filtered for each course.

- Additive Manufacturing Scenario Essentials

- Antenna Placement Essentials

- Composite Structures Simulation Essentials

- Design Exploration Essentials

- Durability Simulation Essentials

- Fluid Simulation Essentials

- Fluid Simulation: Advanced Topics

- Linear Structural Scenario Creation Essentials

- Linear Structural Validation Essentials

- Material Calibration Essentials

- Mechanical Scenario Creation Essentials

- Mechanical Scenario Creation: Linear Dynamics

- Model Assembly Design Essentials

- Motion Analysis Essentials

- Multiscale Experiment Creation Essentials

- Parametric Design Improvement: Fluids

- Parametric Design Improvement: Structural

- Performance Study Essentials

- Performance Trade-off Essentials

- Physics Results Explorer Essentials

- Plastic Injection Essentials

- Plastic Part Filling Essentials

- Process Composer Essentials

- Results Analytics Essentials

- Simulation Model Design Essentials

- Simulation Scripting Essentials

- Static Study Essentials

- Structural Model Creation Essentials

- Structural Model Creation: Geometry and Meshing

- Structural Scenario Creation Essentials

- Structural Simulation Essentials

- Structural Simulation: Heat Transfer and Thermal-Stress Analysis

To find the description of the courses in this section, download the Learning Experience for SIMULIA Structures catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the global public training schedule filtered for each course.

To find a description of the courses in this section, download the Learning Experience for SIMULIA Structures catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the public training schedule for each course.

- Abaqus for Offshore Analysis

- Abaqus/CAE: Geometry Import and Meshing

- Abaqus/Explicit: Advanced Topics

- Adaptive Remeshing in Abaqus/Standard

- Advanced Abaqus Scripting

- Analysis of Composite Materials with Abaqus

- Analysis of Geotechnical Problems with Abaqus

- Automotive NVH with Abaqus

- Buckling, Postbuckling and Collapse Analysis with Abaqus

- Co-simulation with Abaqus and Dymola

- Composites Modeler for Abaqus/CAE

- Connector Elements and Mechanism Analysis with Abaqus

- Crashworthiness Analysis with Abaqus

- CZone for Abaqus

- Electrochemical Simulation with Abaqus for Li-ion Batteries

- Element Selection in Abaqus

- GUI Customization with Abaqus

- Heat Transfer and Thermal-Stress Analysis with Abaqus

- Linear Dynamics with Abaqus

- Metal Forming with Abaqus

- Metal Inelasticity in Abaqus

- Modeling Contact and Resolving Convergence Issues with Abaqus

- Modeling Contact with Abaqus/Standard

- Modeling Extreme Deformation and Fluid Flow with Abaqus

- Modeling Fracture and Failure with Abaqus

- Modeling Rubber and Viscoelasticity with Abaqus

- Modeling Stents Using Abaqus

- Obtaining a Converged Solution with Abaqus

- Structural-Acoustic Analysis Using Abaqus

- Substructures and Submodeling with Abaqus

- Testing and Analysis of Elastomers (In-person only: Course description)

- Tire Analysis with Abaqus: Fundamentals

- Tire Analysis with Abaqus: Advanced Topics

- Writing User Subroutines with Abaqus

To find a description of the courses in this section, download the Learning Experience for SIMULIA Electromagnetics catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the public training schedule for each course.

To find the description of the courses in this section, download the Learning Experience for SIMULIA Structures Catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the global public training schedule filtered for each course.

To find the description of the courses in this section, download the Learning Experience for SIMULIA Structures Catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the global public training schedule filtered for each course.

To enquire about Manatee training and services please contact us through our Manatee page.

To find a description of the courses in this section, download the Learning Experience for SIMULIA Electromagnetics catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the public training schedule for each course.

To find a description of the courses in this section, download the Learning Experience for SIMULIA Fluids catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the public training schedule for each course.

- Introduction to PowerDELTA

- Complete Guide to PowerDELTA (Online only)

- Introduction to PowerFLOW

- Introduction to PowerINSIGHT (Coming soon)

- Introduction to PowerACOUSTICS

- Introduction to PowerTHERM (Coming soon)

To find a description of the courses in this section, download the Learning Experience for SIMULIA Multibody Systems catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the public training schedule for each course.

To find the description of the courses in this section, download the Learning Experience for SIMULIA Structures Catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the global public training schedule filtered for each course.

To find a description of the courses in this section, download the Learning Experience for SIMULIA Fluids catalog.

Most SIMULIA training courses are available as instructor-led or on-demand training; for more about on-demand libraries, visit Learning Experiences for SIMULATION.

Click below to see the public training schedule for each course.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering